Every 3D printing service provider wants their business to run like a Swiss watch. The time from a request to order is minutes, the orders are all sorted through and prioritised easily, machines utilized to full capacity, parts produced and delivered on time, leaving customers satisfied.

However, for many 3D printing service providers achieving this level of coordination remains a juggling act.

In this article, we attempt to uncover the main challenges service providers face when running a 3D printing business and what solutions are available to help you succeed in the dynamic and ever-evolving 3D printing services market.

The 10 key challenges for 3D printing service providers

Business challenges

1. Attracting new leads and converting them into customers

Acquiring new customers and securing repeat business is critical, yet also an ongoing challenge for many 3D printing service bureaus.

For an early-stage business, the ability to convert customers quickly may well be a matter of life and death (not to mention making sure you do so at a cost of acquisition that is lower than the revenues that are produced by the effort).

There’s been no better time for service providers to consider ways how they can mitigate the risks and reach more customers with the help of the technology.

2. Balancing pricing and operational costs

Running a successful service bureau requires a delicate balance between providing services at a competitive price and ensuring profits are made and operational costs covered.

However, for some companies, their pricing strategy consists of copying those offered by their competitors or is simply focused on under-cutting others.

Both these approaches, without a solid understanding of what prices should be charged for your services, can lead to severe financial problems. At worst it could mean the difference between making a profit or a loss.

3. Predicting capacity

With the current uncertainty, it’s difficult to predict future demand and plan capacity.

However, 3D printing businesses must understand their capacity to be able to plan your production efficiency and scale it, as it grows.

Too often, however, a lack of visibility into your capacity can lead your business to overextend its operational capacities, inevitably putting you in a situation where some customers will not receive on-time deliveries.

4. Providing better customer service

With manufacturing businesses focusing on delivery and quality of products to maximize revenue and profit, customer service often falls by the wayside.

Needless to say, customers have higher expectations these days. They value responsiveness, real-time feedback and speed.

However, you’ve been struggling to deliver on these expectations. You’ve probably been in a situation when you got flooded by requests and couldn’t quote requests faster, or couldn’t provide customers with timely status updates.

How you handle your customers is crucial to your business’s success. Handle them poorly, and they bolt to a competitor, slashing revenues.

5. Staying competitive

In 2021, the 3D printing service bureau market is arguably more competitive than ever.

On one hand, many machine OEMs now offer production services alongside selling their machines.

On the other hand, the relatively low cost of professional desktop 3D printers has led to a rise in the number of new service bureaus being founded.

Online manufacturing platforms, based on a Manufacturing-As-A-Service model, are also helping to shape the services landscape by offering companies access to a global network of suppliers, on-demand.

There is a clear opportunity for 3D printing service providers to differentiate themselves from competitors, for example by leveraging their unique expertise.

Operational challenges

6. You’re spending a lot of time pricing parts and verifying that they are suitable for printing

The process of manually pricing parts is long, cumbersome and inefficient. Your team also often has to ensure their files are printable. If there is an issue, they need to repair the files, using a separate software tool.

Further adding to this is the need for a constant exchange of emails with customers to inform or educate them on the options and collect all the necessary data needed for successful printing.

As a result, it can take several hours a day to just calculate part costs, repair files and communicate this information to customers. Your staff could be using this time much more efficiently, for example on more value-generating tasks like improving operations.

7. Current processes lead to errors and re-work

How much does a mistake in data collection cost your business?

Collecting the information about the order manually is extremely prone to errors. This is particularly true for service bureaus that use a combination of systems, such as CRM and accounting systems, spreadsheets and other tools to coordinate activities.

Too often this results in disconnected systems, with staff having to manually input the same information multiple times into multiple systems.

If you are maintaining multiple databases that separately gather data – one for production, for example, and one for ordering and billing – you are exposing your business to risk as you struggle to align data across systems.

8. A lack of visibility and real-time access to data

Having insight into real-time data is crucial for your company’s administration or management.

However, your team struggles to notice any gaps or missed opportunities, since important information can easily become lost in the noise of hundreds of emails, spreadsheets and siloed systems.

Most likely, it’s also difficult to quickly provide customers with updates on their order status, because spreadsheets can’t provide real-time information on where the order is in the workflow.

9. Ensuring quality

3D printing remains an emerging industry, and challenges relating to quality processes and standardization are industry-wide.

However, achieving the right certification for 3D-printed parts remains a challenge for service bureaus today, particularly when it comes to highly-regulated industries like medical, aerospace and defense.

Adding to the challenge is the fact that regulations and standards vary across industries. Attaining ISO 13485 certification, for example, will almost certainly be a must for service providers manufacturing medical devices.

10. Lack of accountability within the team

The day-to-day operations of any business, small or large, are driven by tasks. Managing these tasks effectively is an arduous yet fundamental process.

When you have several orders on your plate to complete in the upcoming days, it’s key to be able to assess the requirements and urgency of those projects.

However, without syncing between team members, prioritization of important tasks, and constant feedback, accountability is hard to foster.

Solving the 3D printing business challenges

Most of these challenges we covered are clear signs that your service provider business can benefit from automation.

Automating manual tasks and processes, as well as helping you coordinate tasks between people and synchronize data between systems, is the capability of 3D printing manufacturing execution and workflow automation software.

What is MES/workflow automation software?

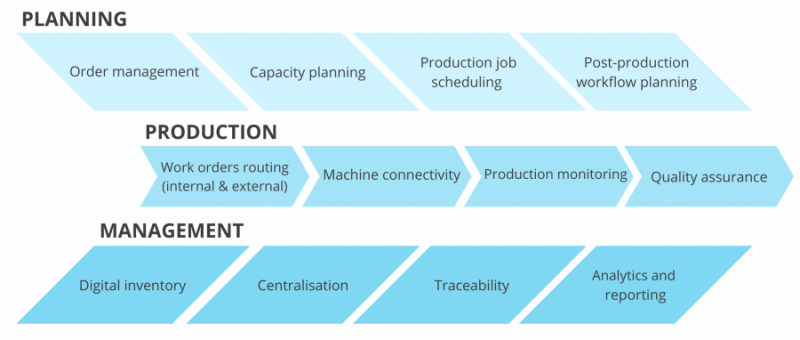

Manufacturing Execution System (MES) and workflow automation software have been specifically developed to overcome the challenges in 3D printing workflow management to bring the benefits of streamlined, coordinated and more efficient 3D printing operations.

MES software, built upon unique requirements of 3D printing and additive manufacturing technology, supports the management, monitoring and automation of all real-time processes.

This can include, but isn’t limited to, automating cost calculations, standardizing requests, conducting printability analyses and scheduling production.

In a section below, we take a look at the different solutions MES workflow automation provides to solve key challenges in managing 3D printing operations.

How can MES workflow solutions help you run a 3D printing business more efficiently?

1. Provide instant quotes to your customers

One way to use workflow software is by integrating an online quotation and ordering portal into your website to allow customers to complete the ordering process by themselves. Such a platform uses your pricing formulae and can also be customized to your brand (think logos, colours, technologies, materials etc.)

A web quotation platform allows customers to receive quotes instantly and without the need to send emails and make calls.

It also helps them to place orders at any time (even outside of your working hours) and complete the buying process intuitively and in a matter of minutes, in the vast majority of cases.

Importantly, you can also track customers who drop off in the RFQ process with a tool that tracks portal activity and re-engage them, ultimately increasing conversion.

Furthermore, implementing an instant quotation platform isn’t only beneficial for your customers – it’s also one of the best things you can do for your team. Being able to automate important yet manual tasks, such as price calculations, allows your team to focus on activities that bring in more revenue.

2. Automate internal cost calculations

Sometimes, you’d want to price requests internally, either because a certain project will require manual review or you’d like to provide a special discount for returning customers.

In any case, you can use the ordering portal to allow your customers to submit requests for internal review.

AMFG’s platform uses a powerful pricing engine and automated file repair tools, helping you to ensure part printability and price it accurately within minutes.

“Our improved efficiency [with the help of AMFG] means that we can also provide an enhanced, tailored service to customers who have more complex projects, or where they require additional downstream services. It’s a win, win!”

Rupert Sleightholme, Projects Manager, ARRK Europe

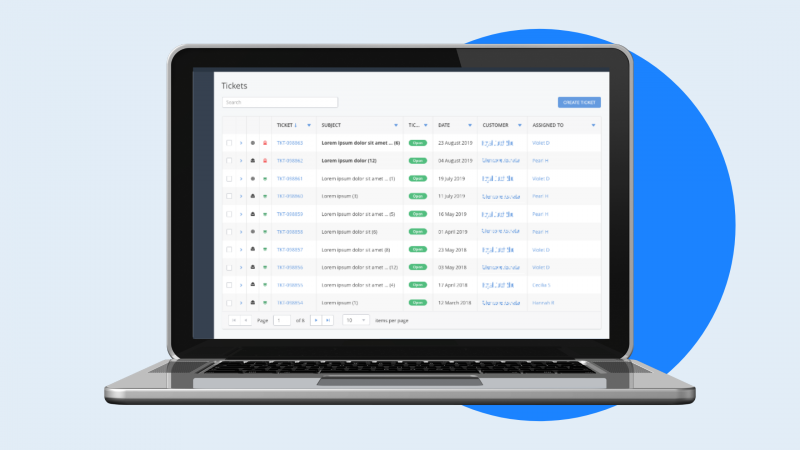

3. Communicate with customers

Spending time on back and forth emails is time-consuming and, if the number of requests is growing, it can quickly become painful to find the right contact or message to respond.

What workflow software does is it centralizes all communication within one platform.

What this means is that you can send messages to customers through the platform. Moreover, you can create and customize templates and set up automated emails to make communication even faster.

One scenario of using this feature is by linking order status to an email template. Once the order status changes – for example, when the order is dispatched – it triggers an automated email to a customer, informing them on this status.

Another way to cultivate good communication with the help of the workflow software is by providing your customers with a personal dashboard, where they can track the status of their orders in real-time.

With such a platform, customers also get access to their order history, where they can easily reorder desirable parts with just one click.

4. Foster accountability through prioritization

This, in turn, allows your team to prioritize more important tasks and work more efficiently because they aren’t going back and forth between inboxes, trying to decide what to do next.

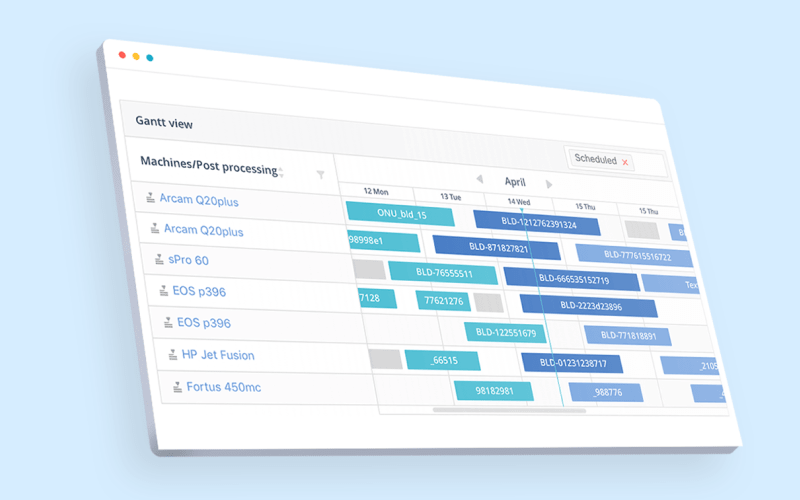

5. Manage and schedule production

Order prioritization will go a long way to help you prioritize certain production jobs. This can help ease your pain and make it easier to produce the parts you need to ship most urgently.

With MES software, scheduling production jobs also becomes easier. AMFG’s platform connects the ordering and production stages, so you can easily assign ordered parts to a build you’ve created based on the technology, machine and material.

Finally, advanced MES software will enable you to connect your 3Dprinters with the software and view machine data, like utilization, job status, processing parameters, and much more.

Armed with the data, you can better understand the operational performance of your 3D printing operations and optimize processes to drive production efficiency.

6. Integrations

Today, 3D printing businesses use a range of different software to ensure the successful running of their operations. For this reason, integration between business-critical systems is vital to ensuring the seamless flow of data between different areas of your company.

3D printing workflow solutions that can be successfully integrated into your current software infrastructure, including ERP and PLM, provides an unprecedented level of visibility, synchronization across and control over the entire 3D printing process.

The benefits of integrating MES workflow software into your 3D printing business

- Automated processes, from quotation to production and dispatch, help you reduce errors, save time and drive increased productivity.

- An increase in leads, and new customers, since a large part of the sales process is automated with the help of a 24/7 ordering portal. As a result, you can capture more leads, increase conversion and ensure scalable growth.

- Shorter lead times. With the time saved and the high level of team coordination achieved, the project can sail smoothly forward and be shipped to the customer faster.

- Improved customer experience. A dedicated portal to sell your services online streamlines the customer journey. A simple reordering process cultivates repeat customers. Plus, the portal creates a professional feel that elevates your brand.

- Better accountability & transparency. With workflow automation systems that help in the robust assigning of tasks, work gets done faster and delivered on time.

- Increased quality and continuous improvement. With man-made errors reduced and all process steps tracked and documented, it’s easier to ensure part quality and uncover opportunities to improve.

“Our turnover has increased by 20%+ year-on-year over the last three years. In the last year alone, we’ve generated over £50,000 revenue just through [AMFG’s] quotation tool…This allows us to deal with the increasing volume of enquiries without compromising on service.”

Jonathan Warbrick, Business Development Manager, Graphite Additive Manufacturing

Automation is the future for the 3D printing service business

A recent report by market research firm, IDC, forecasts that spending on 3D printing services will reach $4.8 billion in 2022, indicating a very promising outlook for the sector in the years ahead.

To fully capitalize on this opportunity, 3D printing service providers will need to automate as much of their business as possible – especially the front-end activities like quoting, order entry and customer service.

MES and workflow software is the ideal automation solution that 3D printing service providers can use today to achieve greater efficiency and business growth in the months and years to come.