Introduction

3D modeling or CAD (Computer-Aided Design) allows engineers and designers to build realistic computer models of parts and assemblies. These models can be then 3D Printed or CNC machined as well as used to run complex simulations. A wide range of parameters can be simulated such as strength or temperature resistance before any physical models have been created, enabling a much faster and cheaper workflow.

Solid Modeling

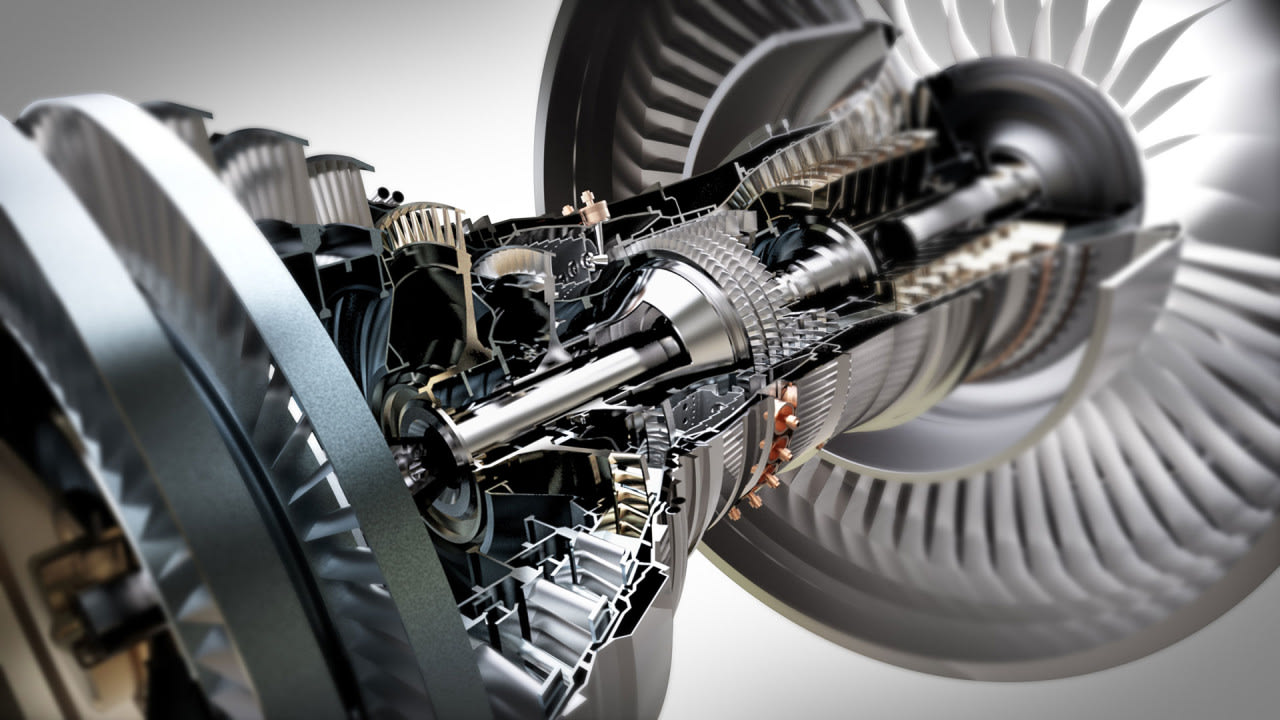

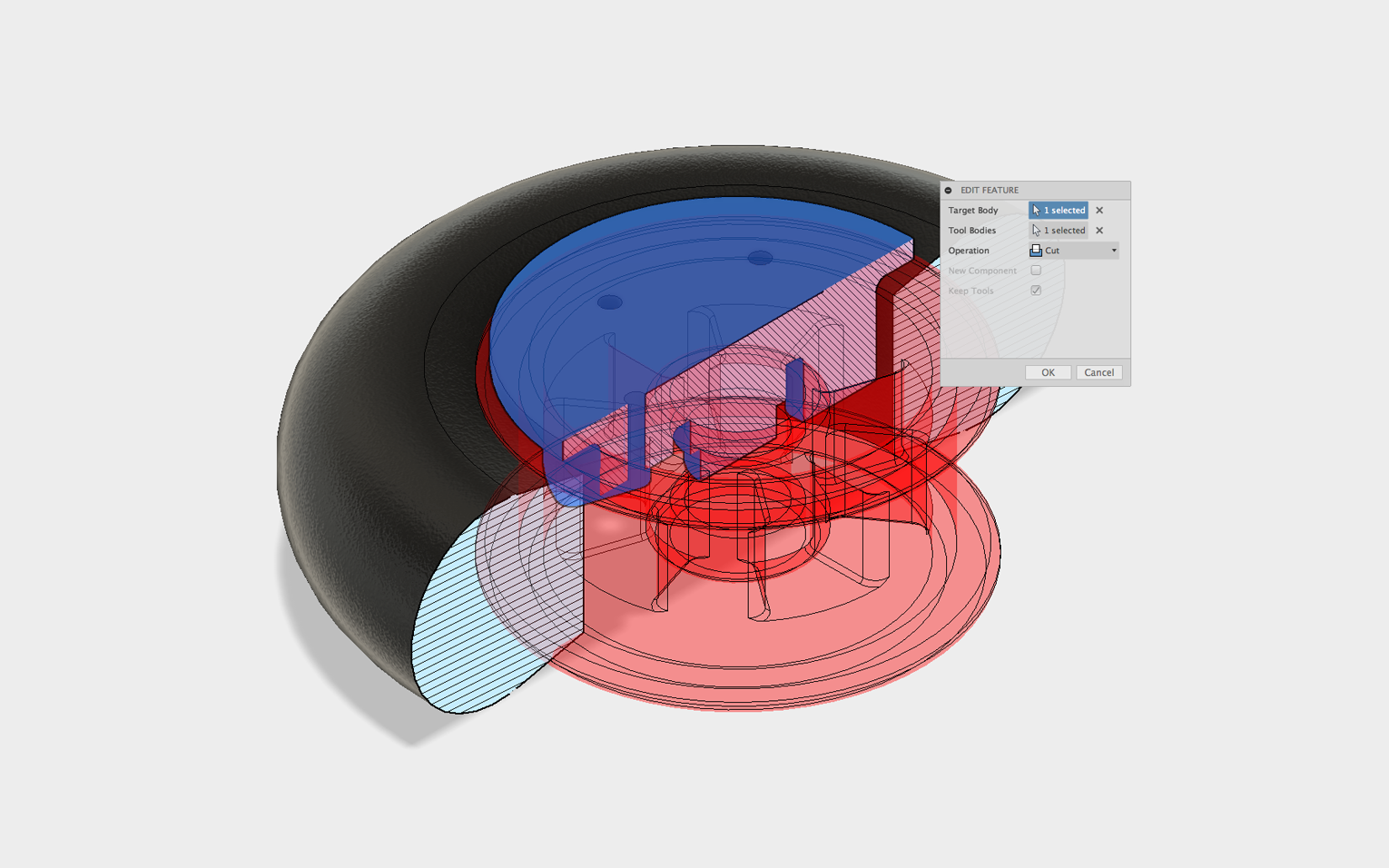

Solid modeling creates solid 3d models as if they are actual parts, with a logical workflow which is similar to the processes which would be used to manufacture the part. Some of these operations include extruding, drilling and threading operations. Solid models can intersect, join and subtract objects from one another to create the desired part.

Another advantage of solid modeling is that it is usually parametric, meaning that changes, or parameters are saved at every stage of the modeling processes and can be edited at any time during the design. This is very useful as it allows features of the model to be quickly modified without needing to create the part from scratch.

Assembly modeling is also an important stage in solid modeling, allowing individual parts to be assembled together, forming complex models. Assemblies can be used to insert standard components such as fasteners or bearings, that have been downloaded directly from the manufacturers. Motion elements can also be applied to assemblies, allowing detailed motion analysis to be used to evaluate the mechanical performance of the design.

Surface Modeling

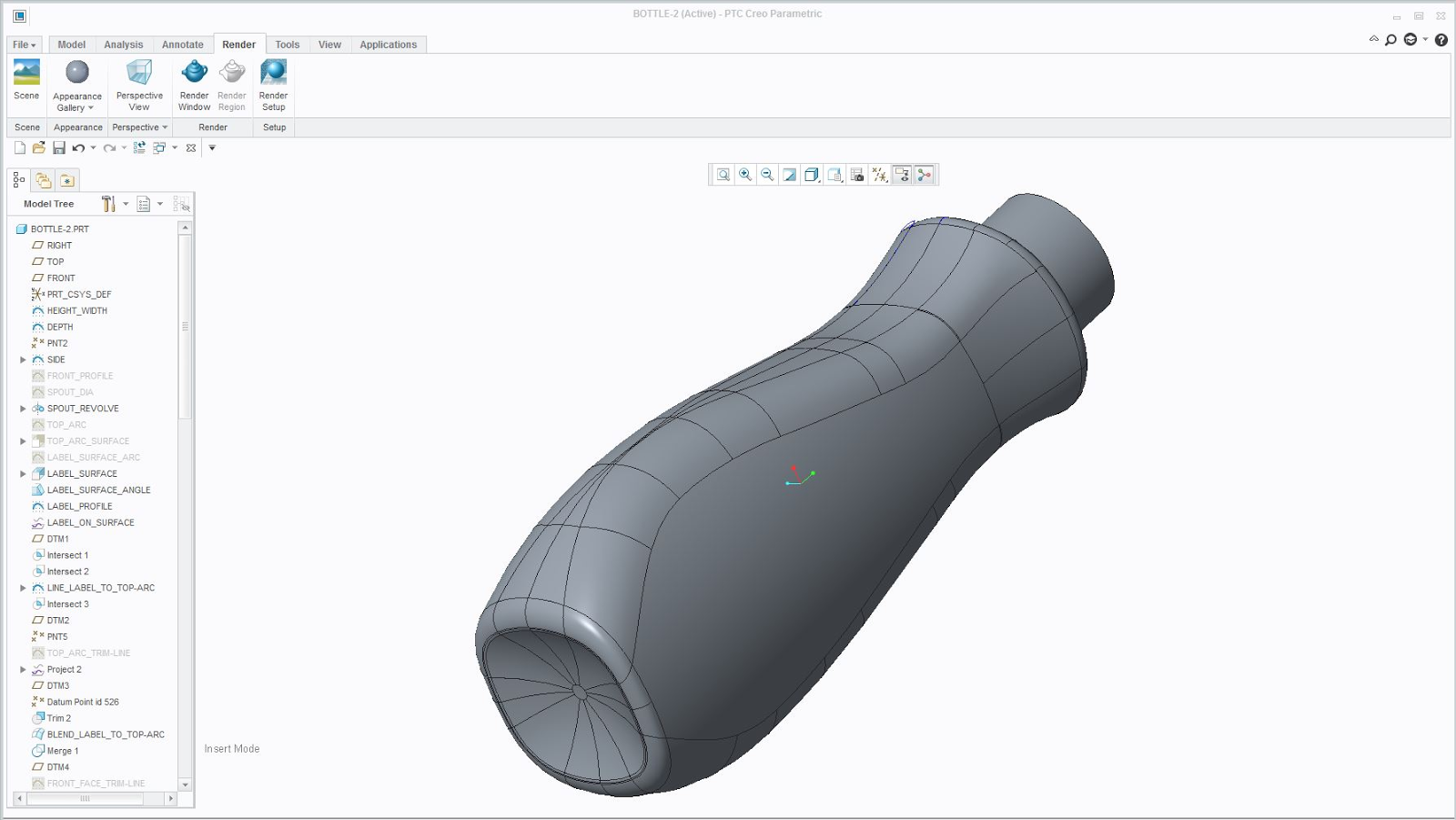

Surface modeling is usually used for more aesthetic features of a product. It is much easier to create more organic and free-form geometry using this type of CAD software. Many of the constraints found in solid modeling are not an issue with surface modeling, however, this comes at a cost of sometimes being less accurate.

As the name suggests surface modeling only contains surfaces of the part, with no solid interior. However, once the part has enough surfaces to close the part, it can be filled and then used for 3D printing. When developing designs using surface modeling, it can be hard to go back and make changes because usually it is not parametric.

Each type of modeling software has benefits and drawbacks, depending on the type of design being produced this needs to be considered. Sometimes using both solid and surface modeling is needed to combine the benefits of each.

Sculpting

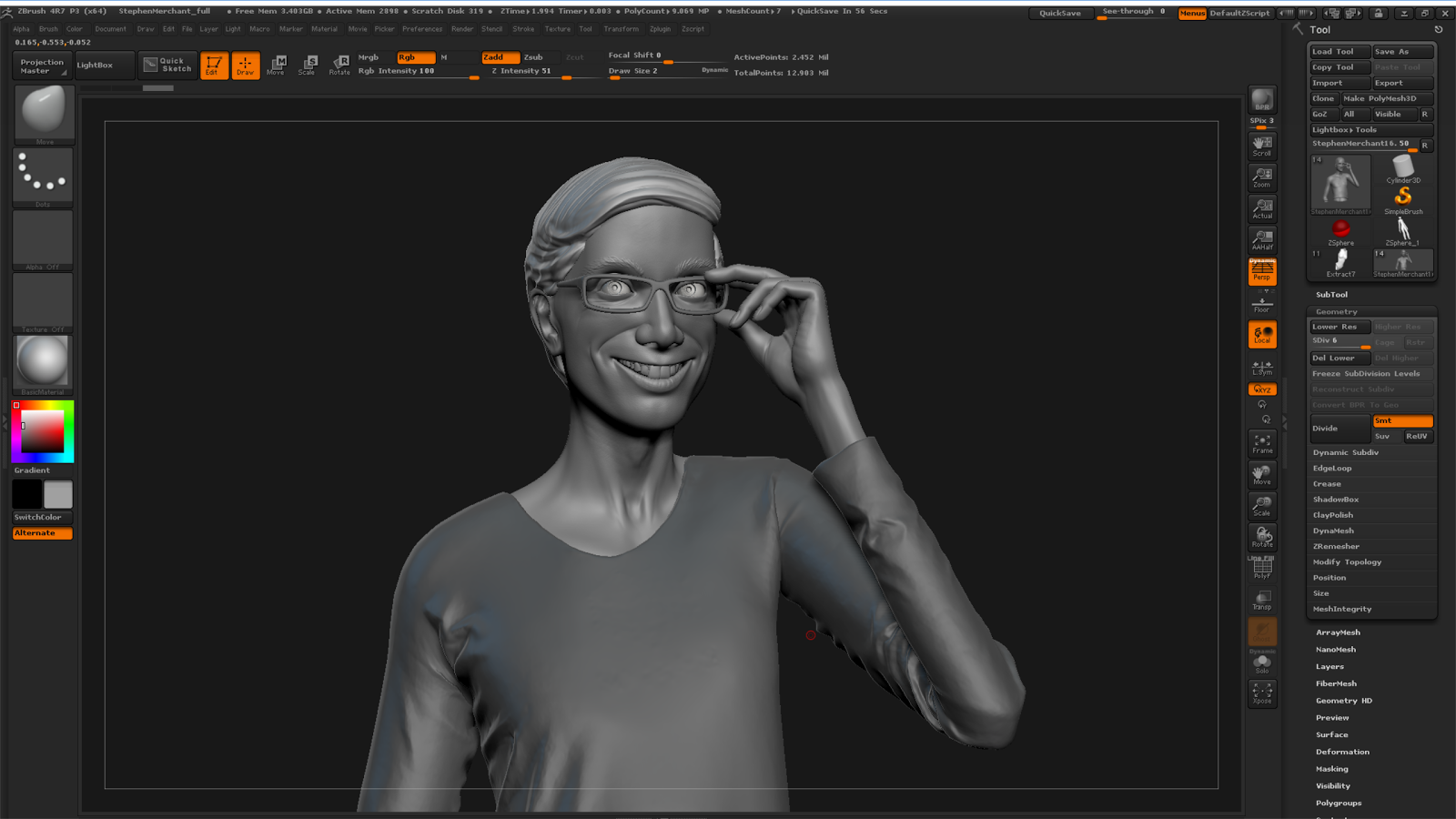

Sculpting or organic modeling is mainly used for creating freeform surfaces with intricate details such as characters, jewelry, or organic shapes found in nature such as trees or rock formations.

Sculpting software packages such as Pixologic’s ZBrush or Autodesk’s Mudbox were designed with classical sculpting in mind. They allow digital sculptors to start from a simulated ball of clay and use a pressure-sensitive drawing tablet or monitor to manipulate their object with brushes that reflect classic sculpting tools such as a small rake or thumbs to move, add or remove material from their object.

Using these tools, artists create sculptures that consist out of tens of millions of polygons that capture all the intricate details of a character’s face in order for these to come alive in big-budget movie productions.

CAD Software

A wide range of CAD software exists with different packages available for a number of different industries. The most common of these are presented in Table 1.

Table 1 – Common industry CAD software programs.

| Software | Description | Common File Type |

|---|---|---|

|

Solidworks – Industry-standard engineering software used for part and assembly modeling, includes simulation features as well as drawing and assembly tools. | .sldprt .sldasmslddrw |

|

AutoCAD – Autodesk AutoCAD, a software package for 2D and 3D CAD, has been used since 1982! AutoCAD is used across a wide range of industries, by architects, project managers, engineers, graphic designers, and many other professionals. | .dwt .dwg |

|

Inventor – Inventor has very similar features to Solidworks, with professional 3D mechanical design, drawing tools, and product simulation tools. | .ipt .iam .idw |

|

Fusion 360 – Autodesk Fusion 360 is gaining a lot of popularity with engineers and designers. It is similar to Solidworks, with the addition of integrated manufacturing tools and sculpting tools. It is also available for free for students, enthusiasts, hobbyists, and startups. | .f3d |

|

Sketchup – Entry-level software which is easy to use but with basic features. Mainly used for applications such as architectural models & interior design. | .skp |

|

Solid Edge – Solid Edge provides solid modeling, assembly modelling and 2D orthographic view functionality for mechanical designers. Solid Edge is a direct competitor to SolidWorks, PTC Creo, and Autodesk Inventor. | .prt .asm |

|

Creo – PTC Creo is a suite of design software with a focus on product design for discrete manufacturers. The suite consists of apps, each delivering a distinct set of capabilities within product development. | .prt .asm |

|

Onshape – Onshape is a full internet based CAD software package. It makes extensive use of cloud computing, with compute-intensive processing and rendering performed on Internet-based servers. | Cloud Only |

|

Rhino – Multi-use, free form surface modeler for engineering, architecture and jewelry design. | .3dm |

|

ZBrush – ZBrush is a digital sculpting tool that combines 3D/2.5D modeling, texturing and painting. The main difference between ZBrush and more traditional modeling packages is that it is more akin to sculpting. | .obj |

|

3ds Max – Autodesk 3ds Max is a professional 3D computer graphics program for making 3D animations, models, games and images. | .3ds .max |

All of the CAD programs shown in Table 1 are able to output STL or OBJ files for 3D printing or STEP and IGES for CNC manufacturing.

Industry Data

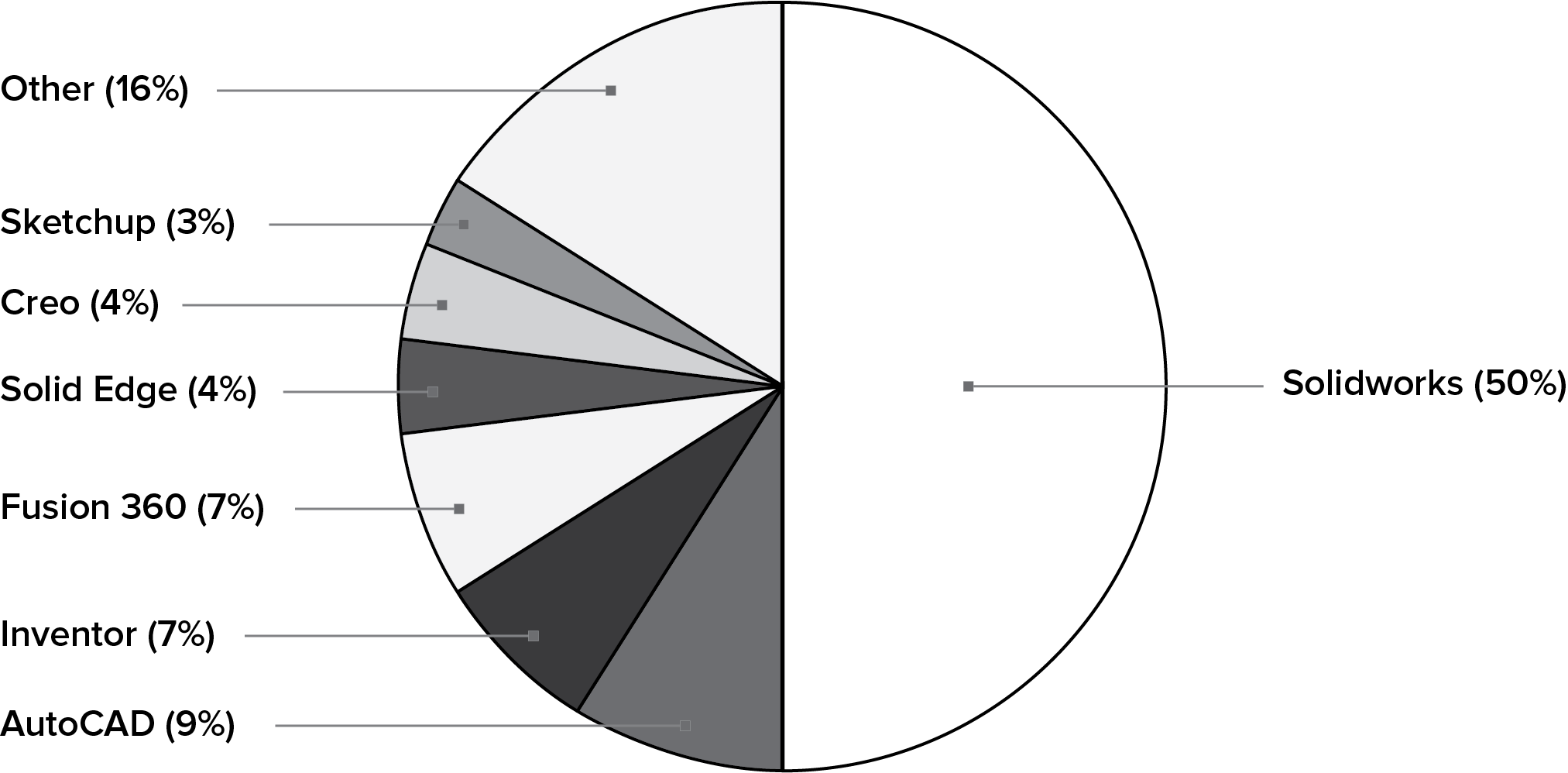

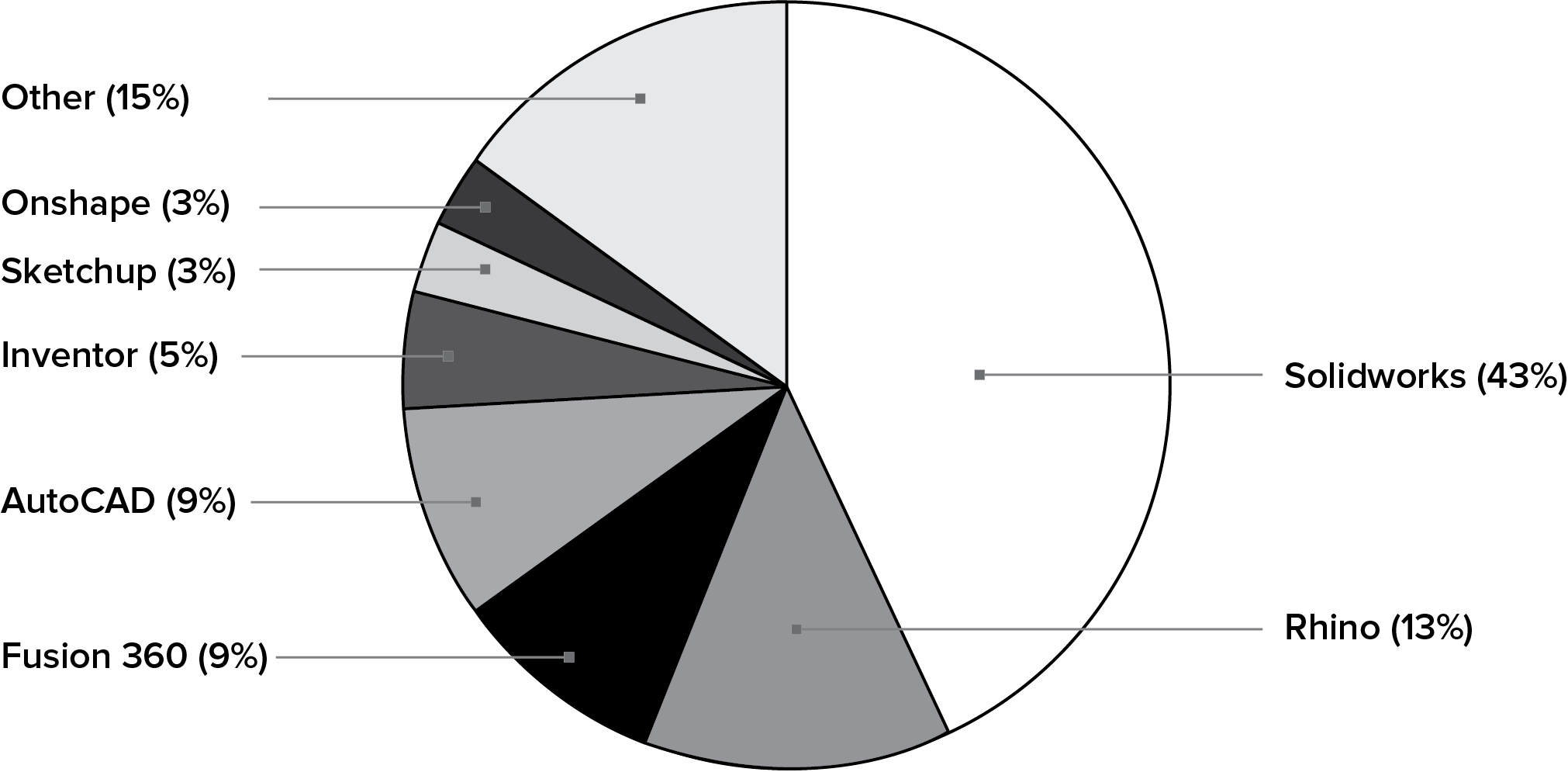

A survey sent out by Hubs to over 750 professional customers asked designers and engineers which CAD software they are currently using. The results are presented in Figure 5 and Figure 6.

The survey found that the majority of engineers and designers use Solidworks for CAD design. Engineers then preferred AutoCAD, Inventor, and Fusion 360 (the only free professional CAD software package on the list) while Rhino proved to be the second most popular modeling tool for designers. As an interesting note, Rhino did not appear on the list for engineers even though it ranked highly for designers.