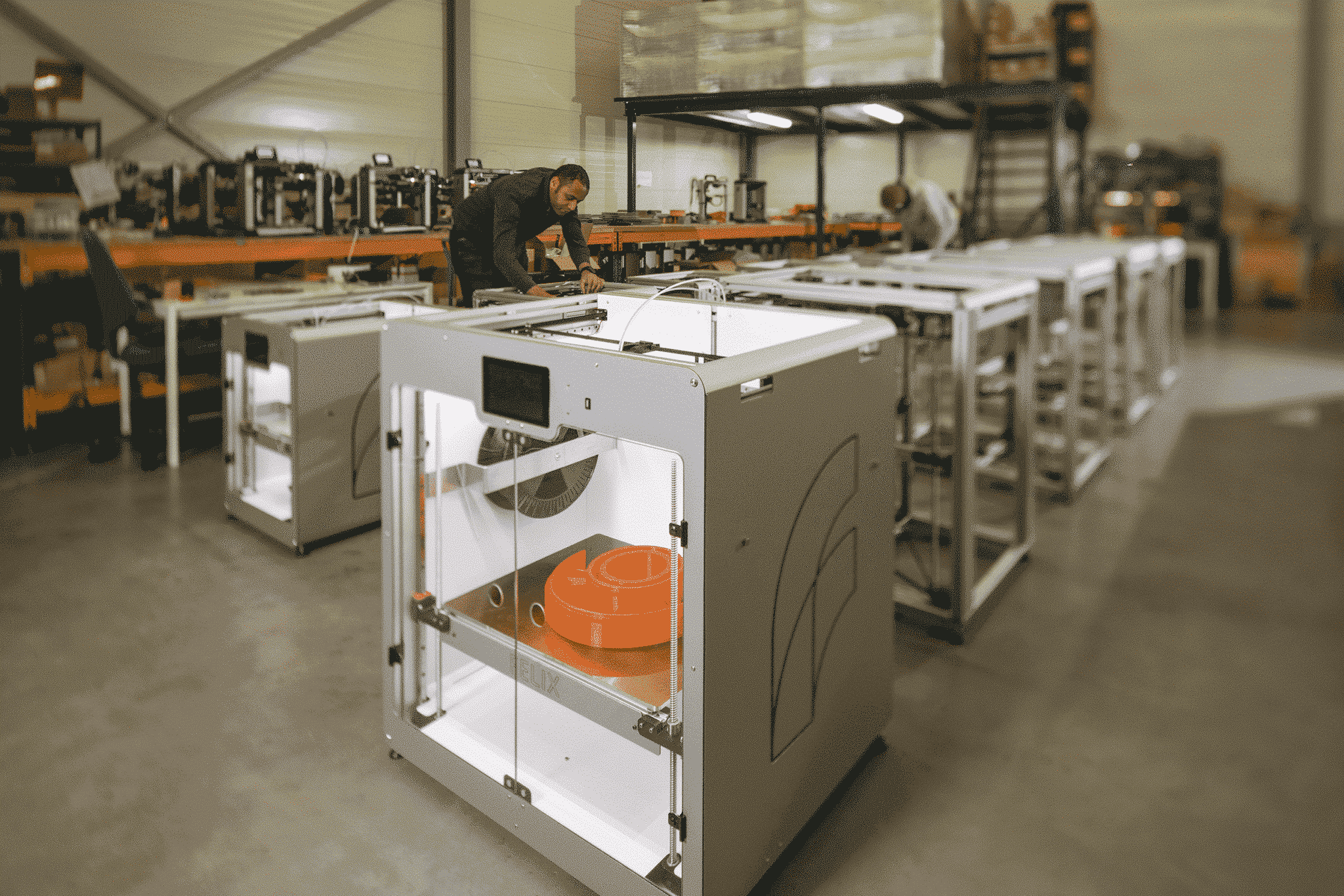

Unfortunately, many people imagine an FDM 3D printer and low-quality plastic models when they hear ‘’3D printing’’. But this technology has come a long way in a short amount of time.

Nowadays, there are whole factories providing you with Additive Manufacturing at the highest standards and quality, capable of mass-producing goods. So, how do different types of industrial 3D printers work?

Traditional FDM 3D printers

Fused Deposition Modeling was developed in the 80s and brought a new revolution to rapid prototyping. At first, it wasn’t very cost-effective, however, it was fast. Now everyone can get a desktop 3D printer and produce simple models in their own house.

FDM 3D printers use plastic filament. The filament comes in a thin thread. It is pushed into a nozzle where it’s heated up, becoming flexible. The nozzle extrudes the filament out in the shape of your model, layer by layer.

FDM printers are capable of pretty thin layers, however, they will also be visible.

Real Additive Manufacturing: Industrial 3D printing

3D printing didn’t stop evolving at FDM printers. Today we have industrial 3D printers that use powder. How exactly does it work and how can powder be turned into a solid object? Let’s find out! There are several materials to talk about: plastic, resin, metal, and multicolor 3D printing.

Turning plastic powder into your functional parts

Industrial plastic 3D printing is based on powder. This powder can be a mixture of different elements. The most basic one is fine polyamide powder. Additionally, it can be enhanced with aluminum particles like our Alumide material.

SLS vs FDM

Plastic 3D printing is still the most popular method. If you’re wondering if FDM technology is good enough for your project, you should also consider SLS. The choice entirely depends on your project.

How is industrial metal 3D printing possible?

Metal 3D printing

Metal 3D printing is pretty powerful and leaders of their industry such as Airbus already utilize this production method to manufacture their fully functional parts. Industrial 3D printers work like plastic ones. A layer of metal powder is spread on the printing bed, then a laser or binding agent is applied locally to solidify the material.

The laser is used for SLM and DMLS technologies, the difference is that in the DMLS process the material is sintered whereas SLM laser fully melts the powder. Binder Jetting, on the other hand, uses a binding agent to fuse the powder.

Liquid 3D printing

Last, but not least, we came to talk about resin Additive Manufacturing. It all started with SLA technology, where a thin layer of liquid resin is spread, and then cured in the shape of the model. The solidified part is lifted then from the liquid resin and the process repeats itself.

But resin 3D printing has been evolving and new, more efficient technologies were developed. One of them is DLS, an innovative method by the world’s leader in resin Additive Manufacturing, Carbon. Their technology is based on continuous 3D printing, unlike SLA where the process has to be stopped to refill the resin tank with each layer. Thanks to that, the parts are produced faster and at the same time, they are stronger.

Is Industrial 3D printing for you?

Real Additive Manufacturing is for anyone who’s production requirements are strength, good quality, and great mechanical properties. From flexible materials to heat-resistant, there are plenty of choices, and one will surely suit your manufacturing needs.

If this topic is interesting for you, check out the 25 best industrial 3D printers. It might also happen that you don’t want to spend hundreds of thousands of dollars on 3D printers, you should consider using an online 3D printing service. All the industrial Additive Manufacturing technologies we just talked about are available to you. Get an instant quote by uploading your file or contact our 3D printing experts to answer any of your questions.

Hungry for more 3D printing news? Sign up for our Newsletter and follow us on Facebook!