In 1983, Chuck Hall, the father of 3D printing, built the world’s first 3D printer and used it to make a small cup. The small black cup is very inconspicuous, but it paved the way for a quiet revolution that is now changing the medical industry.

Here are a few ways that 3D printing revolutionizes the medical industry.

Personalized prosthesis

Amanda Boxtel is a patient with paralysis below the waist. Although the traditional machine set designed by Ekso Bionics can help her move again, she can’t maintain the regularity and freedom of normal movement, and it is uncomfortable to use. Unlike mass-produced traditional prostheses, 3D printed prostheses are customized for each user. By capturing Amanda’s unique size digitally, she got a tailored suit. The 3D printed legs are beautiful, strong and light-weighted, fulfilling her desires in every aspect. Now, this technology can also be used to make ventilated scoliosis scaffolds with beautiful appearance and shape, prostheses and more products.

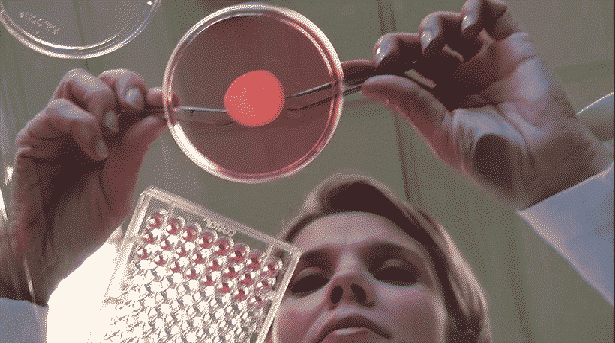

Bioprinting and tissue engineering

Surgeon Jason Chuen wrote in the latest issue of the Australian Medical Journal, reminding colleagues of a major technological breakthrough that human organ transplants will be no longer required eventually. It works as follows:

The process of 3D printing is to instruct the computer to stack layers of specific materials (usually plastic powder or metal powder), casting one layer at a time until the final product (whether it is a toy, a pair of sunglasses or scoliosis support ) is done.

Medical technology now uses this technology to make micro-organs (“organoids”) in the same way using stem cells. Once printed, these organoids can grow in the patient’s body, and can take on heavy responsibilities when organs (the kidney or liver) fails.

3D Printed skin for burn patients

This may sound like a scene from Mary Shelley’s sci-fi masterpiece, Frankenstein, but its impact and cost savings make this technological breakthrough in the field of 3D printing even more significant.

For centuries, when it comes to healing broken skin, the options for burn patients are extremely limited. Skin grafts are painful and leave scary scars; the effectiveness of spa solutions is limited.

But Spanish researchers are now using the principles of 3D printing, prototyping a 3D bioprinter that can generate human skin. The researchers used bio-ink containing human plasma and material extracts obtained from skin biopsies.

The printer is able to generate about 100 square centimeters of human skin in about half an hour. This technology has a bright future and brings the gospel to the majority of burn patients.

Pharmacy

Finally, 3D printing is also expected to change the pharmaceutical industry and greatly simplify the daily lives of patients with multiple diseases.

Many people take a lot of pills every day. People are dizzy about when to take different kinds of pills, the interactions and the requirements of the pills.

Unlike traditionally manufactured capsules, 3D printed pills hold multiple drugs at the same time, each with a different sustained release time.

This so-called “multi-effect pill” concept has been tested on diabetic patients and the results show great promise.

Conclusion

In the medical world, drugs/therapies, organs, and equipment are necessary components. The promising 3D printing technology is bound to revolutionize the medical world.

Thanks to the advantages of precision, speed and substantial cost reductions, the way we treat and manage physical health will no longer be the same, and this is something to celebrate.