Traditional building models are made of cork, balsa wood and foam, which are very labor-intensive and expensive, and the turnaround time can be from weeks to months.

Embracing new technologies is a magic weapon for victory. With the rapid development of digital design and 3D printing technology, you can master the latest technology and form the best testing process.

Thanks to the digital design and reliable 3D printer, compared to competitors, it can provide scale models with less cost and turnaround time.

The super high efficiency and acceptable price make it possible to visualize the models of each period in the design process instead of making one single model in the end. How it can appeal to customers is self-evident.

Benefits of Using 3D Printing in Architecture

Among all the benefits of using 3D printing, we can summarize significant improvements in 4 aspects: cost, time, quality, and workflow.

For models

- Cost and time:Due to the small initial investment and the low cost of model production, 3D printers reduce costs and allow us to produce more models. The printing time is less than the handmade production period. Not to say that architects can just devote minutes to input orders into printers, and do other business with the accompany of unwearied machines.

- Quality:3D printing servers can professionally change the nozzle sizes and help to improve the printing details. It takes years of experience to choose suitable materials and machines for every different model, based on its size and structure and details.

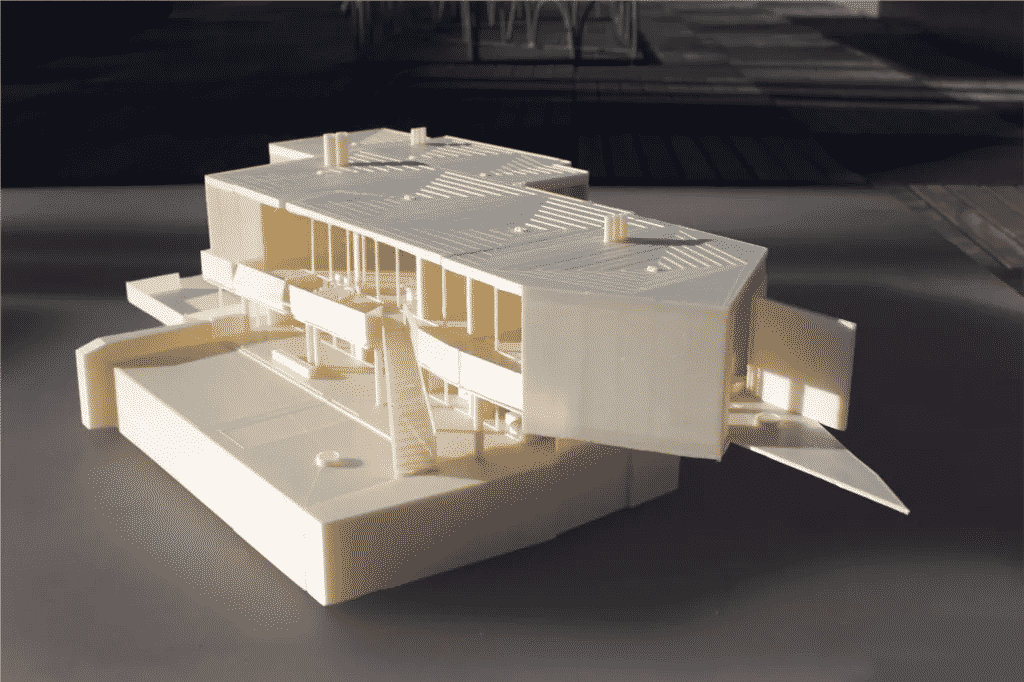

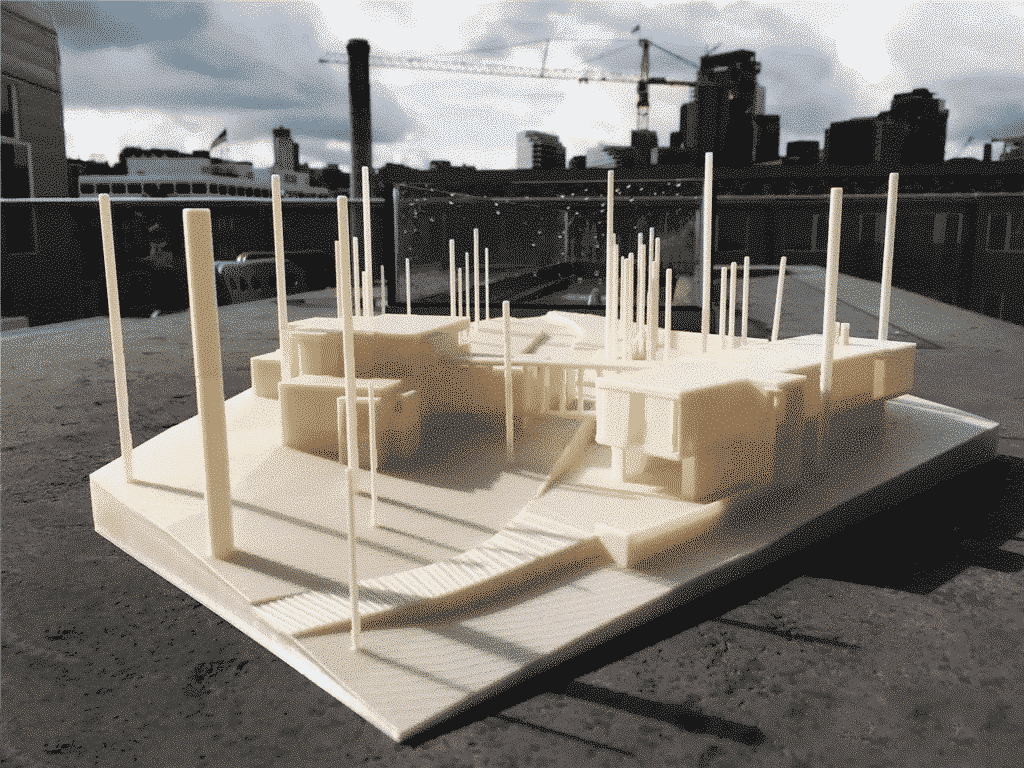

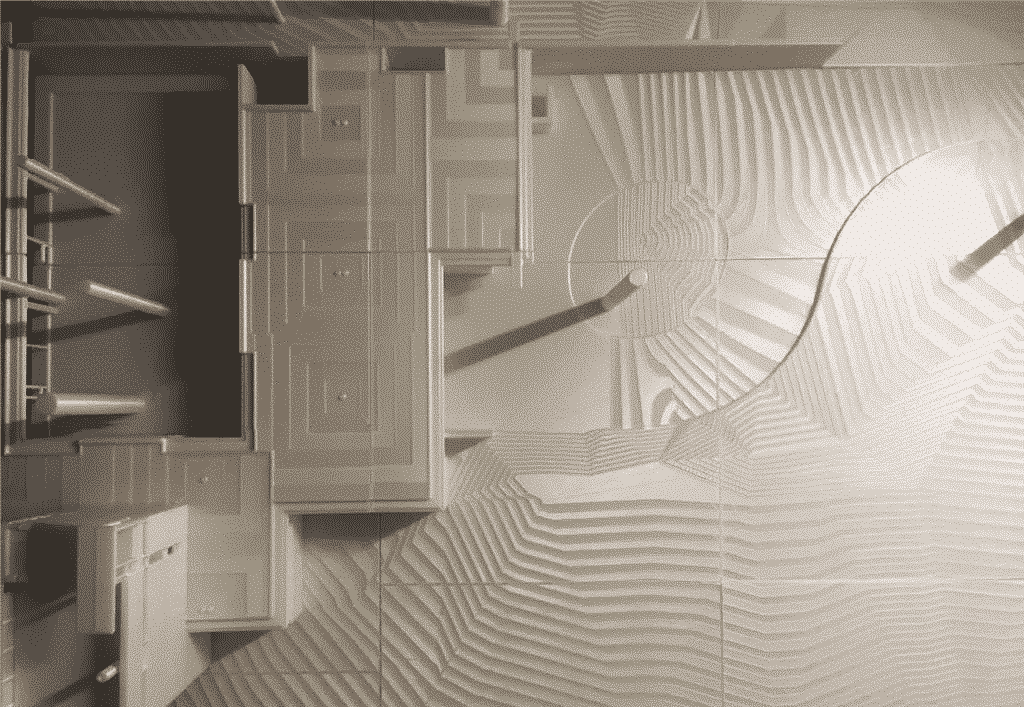

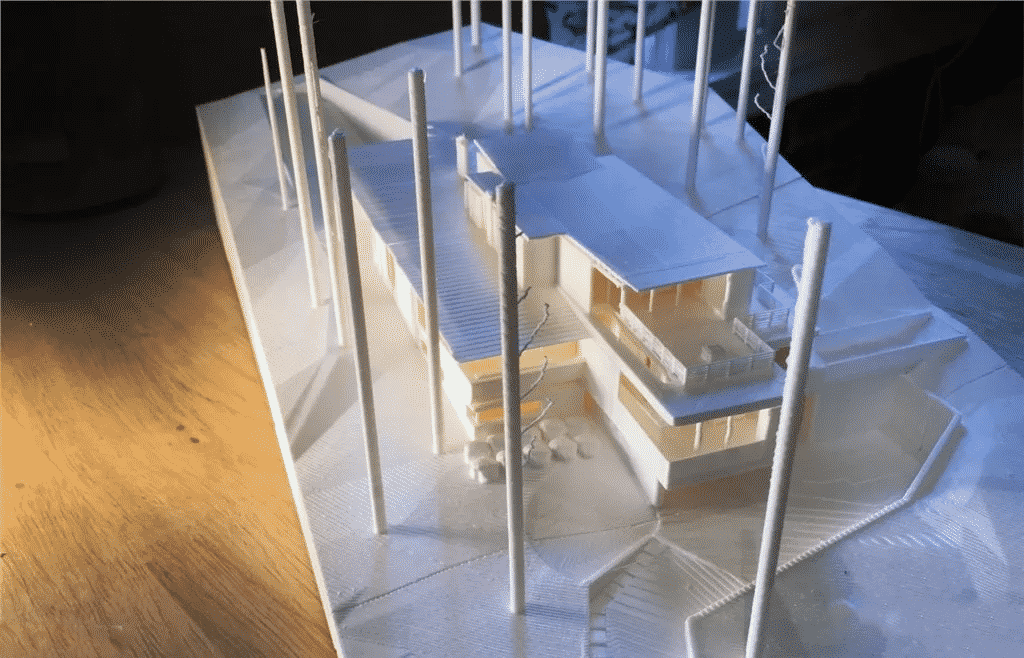

You can print the model in one piece to present the overall features and the supporting facilities. The model is expected to have a smooth surface and precisely reflect all the exterior structures, sometimes painting is needed to attract customers.

When the model is targeted to show the inner structure of constructions, you’d better print the parts separately. The process of printing the model in smaller parts and gluing them together allows the team to spend more time thinking about the overall design and what elements to emphasize during each printing process. In this case, the model needs to be accurately printed, or else any deviation in size and structure will lead to failure in assembling.

For Customers

- Compare different designs:

3D printers can produce different versions of models during the whole stage of communication. You know, nearly all the customers change their minds over and over in the long period communications. Both architects and customers can compare and point out which parts are better and which need to be redesigned.

- Timely communication:

With 3D printed scale models, architects can meet and communicate with colleagues and clients multiple times, collect collaborative responses in time, and make quick changes without spending too much time or money.

The Challenge of 3D Printing in Architecture

- In terms of consumables, excellent adhesion performance is preferred. The consistent results are always appreciated by customers, which is very important in batch production. The shrinkage rate of materials is also important for large-format printing. If the base of the model is large, the printed bottom tends to wrap and ruin the model. Thus you need to adopt a low shrinage-rate material and heat the working platform.

- Some larger models require 100 to 300 hours to print. That is to say, the printer needs to be operating continuously for at least several days, which makes the reliability of 3D printers another key factor.

Conclusion

Architects have become accustomed to investing time and energy into physical models and taking them as the main outcome of their business. In the future, with the development of 3D printing, more architects can obtain better results. And the ever-improving ecology also means architects can enjoy better on-demand printing service, more affordable and high-quality printers and materials, advanced and easy-to-use software, etc.

A 3D printed model can intuitively validate an idea or reflect the flaws in our design. The combination of classical model making with new technologies such as 3D printing has helped architects lift their designs to another level.

“Classic model making methods will always have their place in the architect’s toolkit.”