VALUE-ADDED DECORATING AND ASSEMBLY FOR PLASTIC COMPONENTS

FacFox employs the latest innovations, technologies and automation for our molded plastic components and injection molding assembly, as well as for our secondary and integrated operations. Our process can provide you with fully labeled, decorated and assembled plastic injection molded parts and sub-assemblies for improved quality, increased efficiencies and overall cost savings. Whether your order consists of vacuum metalized plastic parts that require specialized assembly and packaging or you are looking for welding services for your custom injection molded plastics, we have the experience and integrated operations to meet your needs.

1.Decorating and Labeling Injection Molded Components

- In-mold decorating (IMD) and In-mold labeling (IML)

- Silk Screening

- Pad Printing

- Hot Stamping

- Vacuum Metalized Plastic Parts

- CNC Trimming

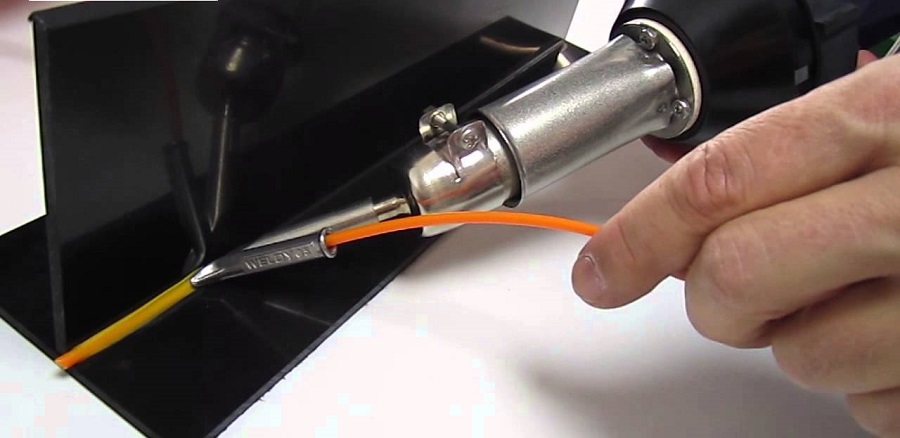

2. Welding of Plastic Molded Parts

a. Ultrasonic welding

b. Spin welding

c. Vibration welding

3. Secondary CNC Machined Parts

4. Assembly

5. Packaging Components

From concept to delivery, FacFox provides competitive advantage in custom injection molded plastics through early production team involvement in the design and engineering phase, design for manufacturability, project management, in-house mold building, material selection support for rotational molding and blow molding.

Add a Comment

You must be logged in to post a comment