In the rapidly evolving landscape of industrial manufacturing and medical technology, the design of micro-porous structures has emerged as a game-changer. These structures are driving significant advancements across various fields by enhancing the surface area of materials, leading to more efficient and compact energy storage and management solutions. In the medical sector, micro-porous structures are revolutionizing minimally invasive surgeries, utilizing cutting-edge techniques like laparoscopy and thoracoscopy to minimize surgical trauma and expedite recovery. This approach aligns with the principle of achieving optimal therapeutic outcomes with minimal intervention, significantly reducing patient pain and recovery time.

FacFox’s unique micron-level 3D printing technology has further advanced the development of micro-porous structures, ushering them into the “micron era.” With a surface roughness (Ra) value of 0.8-2.8μm, these structures ensure smooth flow within micro-channels, and the minimum forming pore size of 50-100μm opens up new possibilities for industrial design.

Key Features and Advantages

- High Surface Area: Micro-porous structures possess an extremely high specific surface area due to their small pore size. This makes them ideal for supercapacitors, as they provide numerous charge storage sites, thereby increasing energy density. Micro-porous carbon materials, for example, can significantly enhance the performance of supercapacitors.

- Excellent Mass Transfer: These structures facilitate the transfer and diffusion of substances within the material, improving mass transfer performance. In the pharmaceutical field, micro-porous materials can be used as drug carriers for controlled release, ensuring stable drug release in the body and maximizing therapeutic effects.

- Lightweight: Micro-porous structures can maintain material lightness while improving strength and toughness through intelligent structural design. This meets the lightweight requirements of aerospace and automotive industries, where reducing weight without compromising strength is crucial.

- Superior Mechanical Properties: Research and scientific reports indicate that samples prepared using micron-level SLM (Selective Laser Melting) technology exhibit enhanced mechanical properties, making them suitable for high-performance applications.

- Wide Material Application: 3D printing, with its unique processing technology, can adapt to various metal materials, including refractory metals. This versatility provides more options for manufacturing micro-pore sizes, catering to diverse industrial needs.

Market Application Cases

Aerospace Components

These components are primarily used in fluid dynamics and pressure experiments, playing a crucial role in automated production, robotics, and aerospace testing and maintenance. For instance, an L-shaped pipeline sample with a diameter of 100μm at the small end requires confirmation of the inner wall’s smoothness to ensure proper flow and accurate test parameters.

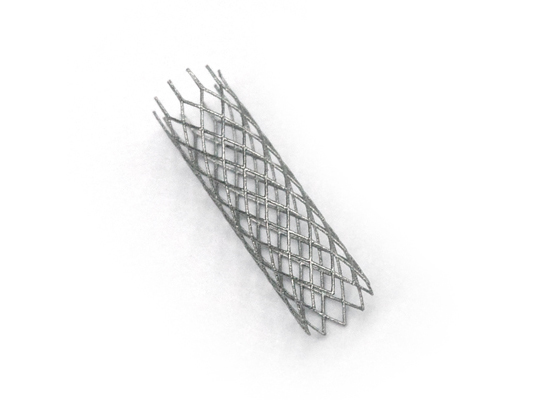

Medical Coronary Stent

These stents incorporate drug injection methods to effectively reduce the risk of wound infection. With a minimum wall thickness of 30μm and a hollow stent diameter of ≥100μm, they are printed as a single piece using medical-level stainless steel, ensuring good biocompatibility.

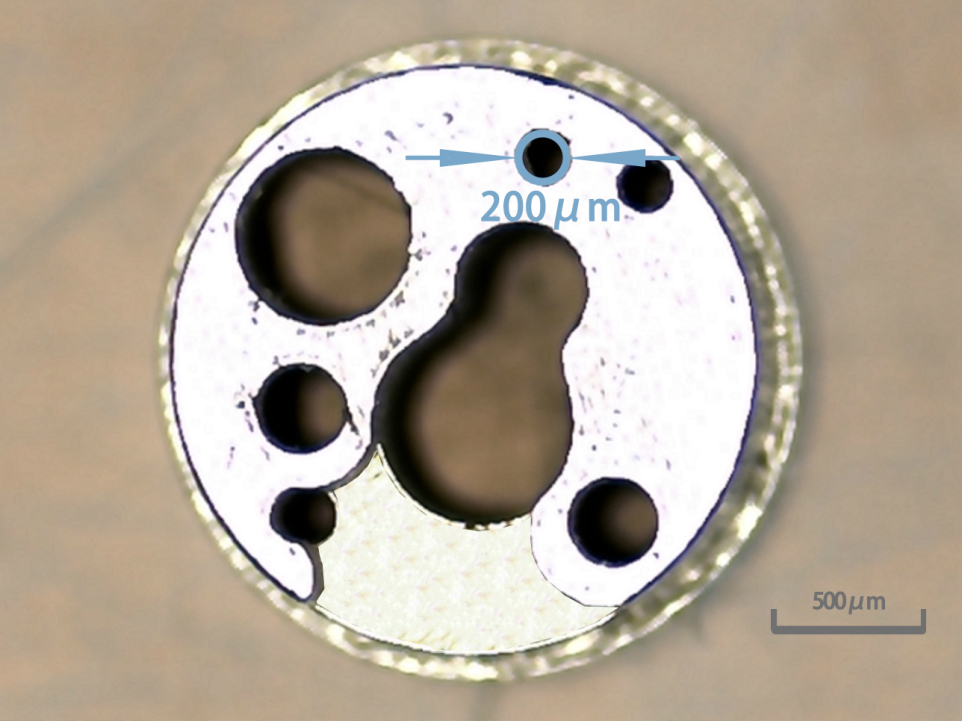

Medical Samples

A 3mm diameter sample designed with seven pore structures, the smallest forming pore being only 200μm. This design meets specific functional transmission needs and improves overall performance through intelligent layout, greatly expanding design possibilities.

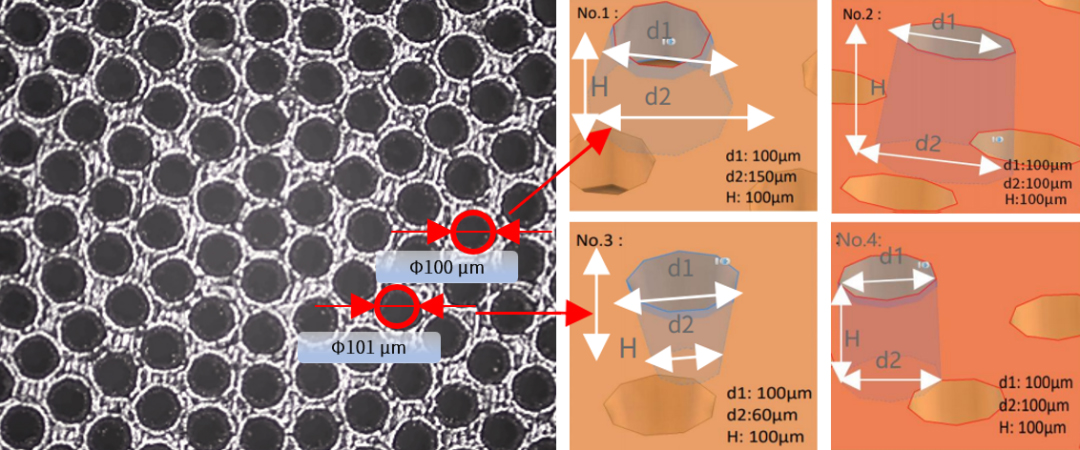

Micro-Porous Matrix Structures

Comprising multiple pores with diameters ≥100μm, these structures must ensure dimensional accuracy, flow, and integrity of each pore. They exhibit high internal smoothness, with strict control over energy density and temperature gradient variations during printing.

Comparison with Other Processes

- SLS (Selective Laser Sintering): This process results in relatively poor surface quality due to the powdery surface of the formed parts.

- EBM (Electron Beam Melting): Conducted in a vacuum environment, EBM reduces oxidation and other adverse factors, theoretically achieving higher precision and surface quality. However, it is costly and has limitations in large-scale production.

- Electrolytic Process: This process may produce stray electric field corrosion during processing, affecting precision and surface quality. Subsequent processing costs are high.

- CNC (Computer Numerical Control): When processing small holes, the cutting area is inside the workpiece, making chip removal and heat dissipation challenging. This can affect processing precision and surface quality. Additionally, small hole processing is limited by tool size and rigidity.

FacFox is dedicated to full-size laser additive manufacturing equipment and product manufacturing. In addition to conventional precision, the company possesses exclusive micron-level metal additive manufacturing technology (Micro-LPBF/SLM), significantly optimizing the precision (≥2 microns), surface roughness (Ra≥0.8 microns), and enabling unsupported printing of various structures above 10 degrees.