RTV (Room Temperature Vulcanization) molding and 3D printing are revolutionizing the manufacturing and prototyping industries. Each technology offers unique strengths, but together, they create an unbeatable combination of efficiency, precision, and creativity.

RTV Molding: An In-Depth Look

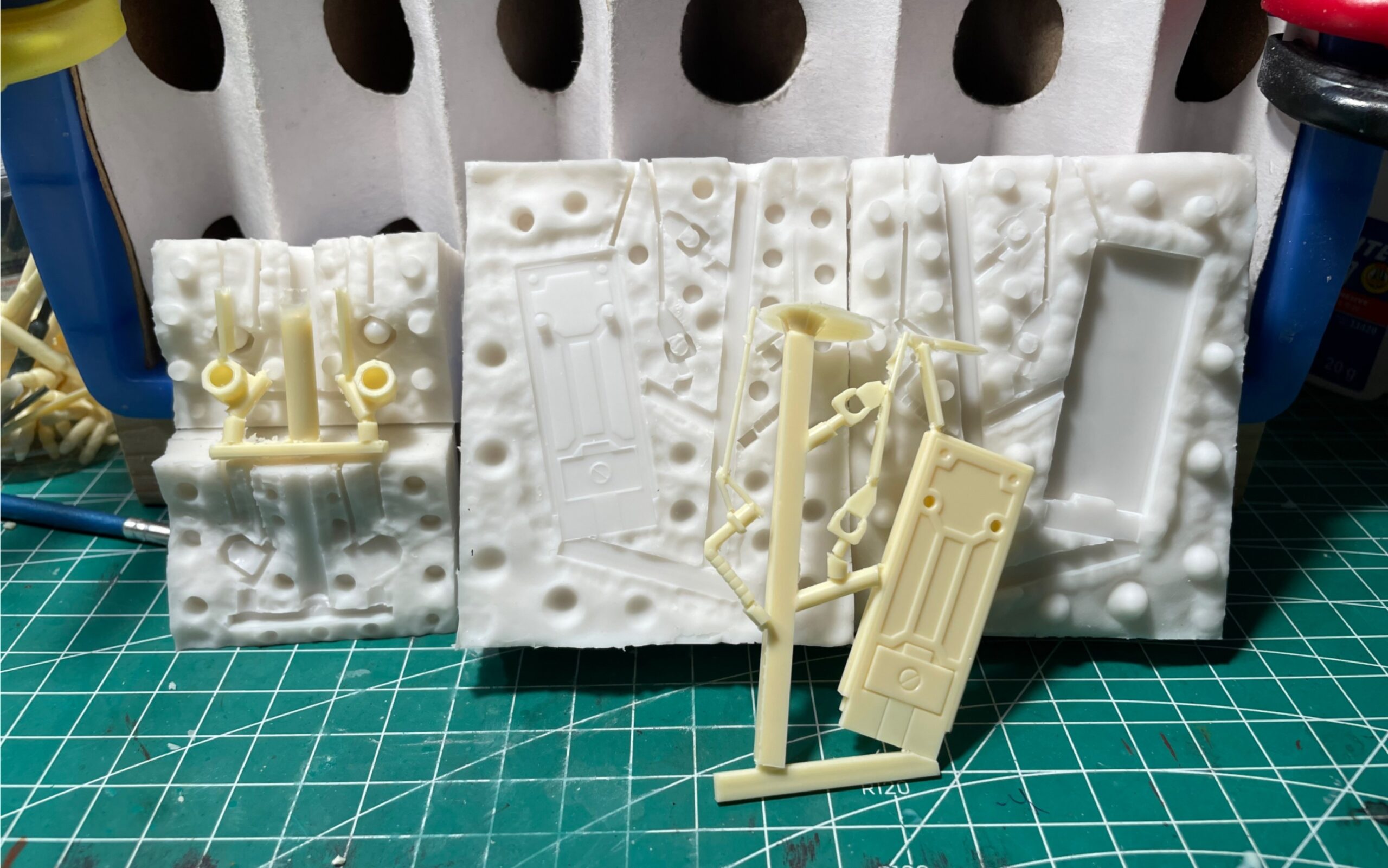

RTV molding, commonly using silicone, is known for its ability to capture intricate details and textures. This makes it ideal for high-quality prototypes and short-run productions. The process involves several key steps:

- Master Model Creation: A detailed master model is often created using 3D printing, ensuring precision and consistency.

- Mold Preparation: The master model is placed in a mold box, and liquid silicone is poured over it, capturing all intricate details. The silicone is mixed with a curing agent and poured over the pattern, taking up to 24 hours to cure.

- Curing: The silicone cures at room temperature, forming a strong yet flexible mold ready for use almost immediately.

- Casting: Various materials, such as urethane thermoset plastic known for its wide range of mechanical, visual, and electrical properties-are cast into the mold, replicating the master model with high fidelity.

Key Advantages

- Retains Tiny Features: The mold material retains tiny and detailed features and tolerances similar to those in 3D printed parts (minimum features 0.025″/0.6mm).

- Versatile Patterns: Wood and metal can be machined to make the pattern, but 3D printing the mold pattern has shown to reduce lead times by up to 90% and costs by up to 70%.

- Durable Molds: Molds can be used for up to 100 parts, typically between 15-30 units per mold, depending on the casting material.

Cost Breakdown

- Pattern Cost: Varies based on geometry; 3D printing is a primary method, followed by subtractive CNC parts.

- Mold Cost: Mainly depends on the amount of silicone used, which costs around $11/in³.

- Unit Cost: Determined by the geometric volume of the part and post-processing work required.

For example:

- Pattern: $320

- Mold: $900

- Unit: $70/unit

- Mold Life: 30 sets

- Per Unit Cost: ~$110

3D Printing: The Frontier of Innovation

3D printing, or additive manufacturing, builds objects layer by layer from digital models. This technology allows for the creation of complex geometries and detailed designs that traditional methods struggle to achieve.

Key Advantages:

- Rapid Prototyping: Swift iterations and concept testing.

- Customization: Production of bespoke parts tailored to specific needs.

- Material Versatility: Utilization of various materials, including plastics, metals, and composites.

Synergy of RTV Molding and 3D Printing

Combining RTV molding with 3D printing maximizes the strengths of both technologies:

- Master Model Production: High-precision 3D printed master models ensure consistent and accurate molds.

- Efficiency and Cost-Effectiveness: 3D printing excels at prototyping, while RTV molding is perfect for cost-effective short-run production.

- Design Flexibility: Rapid iteration and refinement of designs using 3D printed masters and RTV molds.

- High-Quality End Products: Detailed RTV molds and precise 3D printed masters result in superior-quality products.

Pros and Cons

Pros:

- Lower Lead Time and Upfront Costs: Compared to injection molding.

- Lower Production Costs: Compared to 3D printing.

- Minimal Post-Production: Due to the high-quality finish of RTV molds.

- Material Properties: A wider range of casting materials with improved mechanical properties.

Cons:

- Limited Mold Life: Molds must be reproduced every 20-100 units.

- Surface Contaminants: Can inhibit the curing process.

Comparison with 3D Printing and Injection Molding

3D Printing:

- Ideal for rapid prototyping and low-volume production.

- Costs increase with part size and complexity.

Injection Molding:

- Best for large-scale production.

- Higher upfront costs and lead times, but lower per-unit costs for large volumes.

RTV molds offer flexibility and detail that traditional injection molds cannot, making them ideal for detailed design features and small production runs of up to 500 units.

FacFox: Your Partner in Advanced Manufacturing

At FacFox, we combine RTV molding and 3D printing to deliver innovative solutions tailored to your specific needs. Our state-of-the-art technology and skilled professionals ensure high-quality results, whether for prototyping, small-run production, or custom manufacturing. Explore our services and experience the FacFox difference today.

Unlock the future of manufacturing with FacFox’s RTV molding and 3D printing solutions.