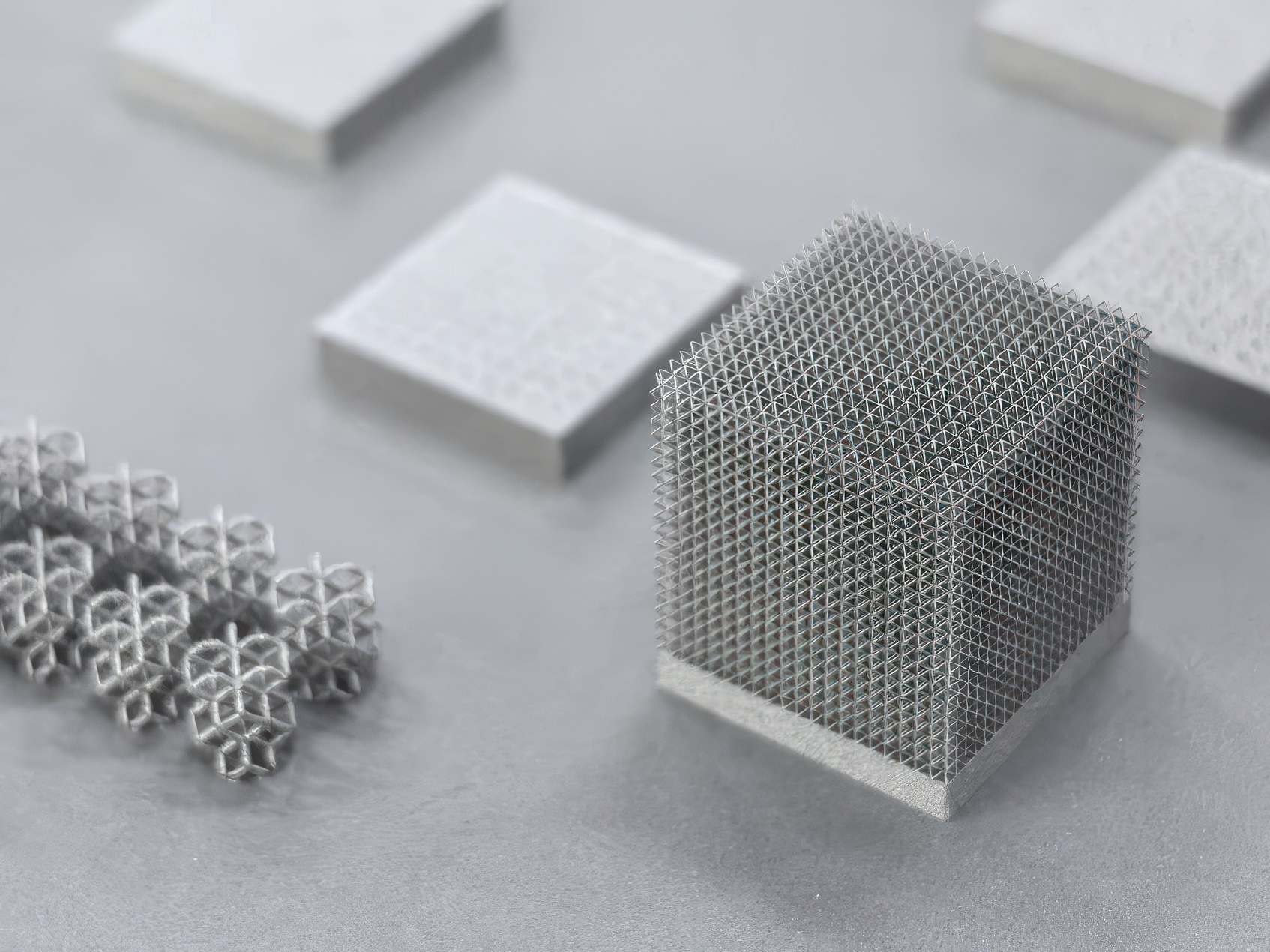

Lattice structures are highly optimized geometric configurations characterized by a series of discrete, orderly arranged points or rods interconnected to form an overall structure. This design significantly increases the surface area of the material and, due to its unique mechanical properties and excellent support capabilities, shows extensive application potential across various fields. When this technology is advanced to micron-level metal 3D printing, its advantages are notably enhanced, bringing revolutionary changes to precision manufacturing, microelectromechanical systems (MEMS), biomedical engineering, and more.

Enhanced Lattice Structures in FacFox’s Micron Metal 3D Printing

FacFox’s micron-level metal 3D printing employs advanced manufacturing processes to significantly upgrade lattice structures. Specifically, the rod diameter is reduced to 60μm, and the grid gap is minimized to ≥200μm. This makes the structure appear denser, yet from certain angles, it allows easy visual penetration. The key characteristics of lattice structures include:

- High Surface Area Ratio: By reducing the continuity of solid material, lattice structures increase the surface area, facilitating processes such as heat exchange, gas permeation, or chemical reactions.

- Lightweight and High Strength: Through finely designed connection points and rods, lattice structures can maintain high strength while significantly reducing overall weight, achieving lightweight design.

- Excellent Support: The complex internal structure provides effective support for unstable parts during the printing process, reducing the risk of deformation and cracking.

Applications of Lattice Structures in Micron Metal 3D Printing

- Ultra-Thin Wall Printing: In the printing of ultra-thin wall metal components, lattice structures can serve as internal support structures, effectively alleviating thermal stress generated during heating, maintaining the flatness and shape accuracy of thin walls. Additionally, by designing reasonable connection structures, the forces between thin walls can be balanced, reducing deformation.

- Thermal Management: In applications requiring efficient heat conduction or thermal insulation, lattice structures can achieve precise thermal management by optimizing their geometric shape and material selection.

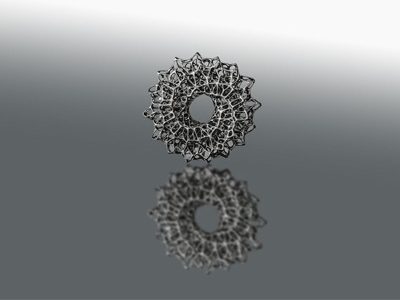

- Biomedical Engineering: In the biomedical field, lattice structures can be used to manufacture bone tissue engineering scaffolds, vascular stents, and other devices with specific porosity and mechanical properties. These scaffolds not only promote cell growth and tissue regeneration but can also be adjusted to match the biomechanical needs of different body parts.

Advanced Applications and Future Prospects

Lattice structures are not only beneficial for traditional applications but also open new possibilities in advanced fields:

- Heat Exchangers and Cooling Systems: The additional surface area of lattice structures can be utilized in heat transfer applications, such as heat exchangers and cooling systems, where efficient thermal management is crucial.

- Catalytic Converters and Filtration Systems: The high surface area and customizable porosity of lattice structures make them ideal for catalytic converters and filtration systems, enhancing chemical reactions and filtration efficiency.

- Aerospace and Automotive Industries: Lightweight and high-strength lattice structures are increasingly being used in aerospace and automotive industries to reduce weight while maintaining structural integrity, leading to improved fuel efficiency and performance.

As technology continues to advance, the applications of lattice structures in micron-level metal 3D printing will further expand. In the future, we can expect to see more innovative designs, multi-material printing, and other advanced technologies, achieving more complex and intelligent functional structures. With deeper research into materials science and computational mechanics, the performance of lattice structures will also be further optimized and enhanced, bringing revolutionary changes to more fields.

FacFox’s Micron Metal 3D Printing Services

FacFox’s micron metal 3D printing capabilities are truly exceptional, offering unparalleled precision and quality.

- Our printing accuracy ranges from 2 to 10 microns, with a surface roughness (Ra) of 0.8 to 2.8 microns, ensuring a smooth finish.

- We can form a variety of structures above 10° without the need for supporting structures, enhancing design flexibility and efficiency.

- Our typical layer thickness is just 5 microns, allowing us to meet the stringent demands of precision structures.

Whether you need intricate components or highly detailed parts, FacFox’s advanced 3D printing technology delivers the accuracy and reliability you require. Explore the future of manufacturing with FacFox and experience the revolutionary potential of micron metal 3D printing for your next project. Visit FacFox to learn more and get started today!