FacFox offers several different nylon plastic materials: Selective Laser Sintering (SLS) PA12 known as Versatile Plastic, Selective Laser Sintering (SLS) PA11, Multi Jet Fusion (MJF) PA12, and Multi Jet Fusion (MJF) PA12 Glass Beads. SLS materials are produced using EOS machines while Multi Jet Fusion materials are produced using HP machines. While the material properties are similar, they are each slightly different, making each more suited for a specific application over another.

Below we’ll discuss what makes each material special and then compare their technical specifications.

Selective Laser Sintering (SLS) PA12

SLS PA12, otherwise known as Versatile Plastic, is the most widely used 3D printed plastic due to its balanced property profile. These balanced properties, including high strength and good chemical resistance, make it a great multipurpose material suitable for a wide range of functional applications. Machines producing SLS PA12 have the largest build platform, allowing larger parts to be printed. A range of colors is available that is not available in the other nylon materials. Several finishes are also available for SLS PA12 including Processed, a tumbled finish which removes some material to create a smoother finish, and Premium, the smoothest finish with a semi-glossy surface.

Multi Jet Fusion (MJF) PA12 & PA12GB

PA12 produced using Multi Jet Fusion technology has very similar properties to Versatile Plastic / PA12 produced with SLS. However, due to slightly different printing technology, it has more consistent, isotropic properties throughout the part. For example, SLS PA12 will have slightly compromised strength in the z-axis of printing (between printing layers). Multi Jet Fusion PA12, however, has the same strength in the z-axis as the x-y (within layers). MJF PA12 also has a slightly higher elongation at break. This improved elasticity makes it more resistant to breakages and as a result, thinner wires and wall features are able to be produced. Multi Jet Fusion is printed at a lower layer thickness over SLS PA12 providing better resolution of small details. Additionally, Multi Jet Fusion produces a final part with a surface that is slightly more sealed than those produced with SLS. As a result, for some geometries, watertight properties can be achieved.

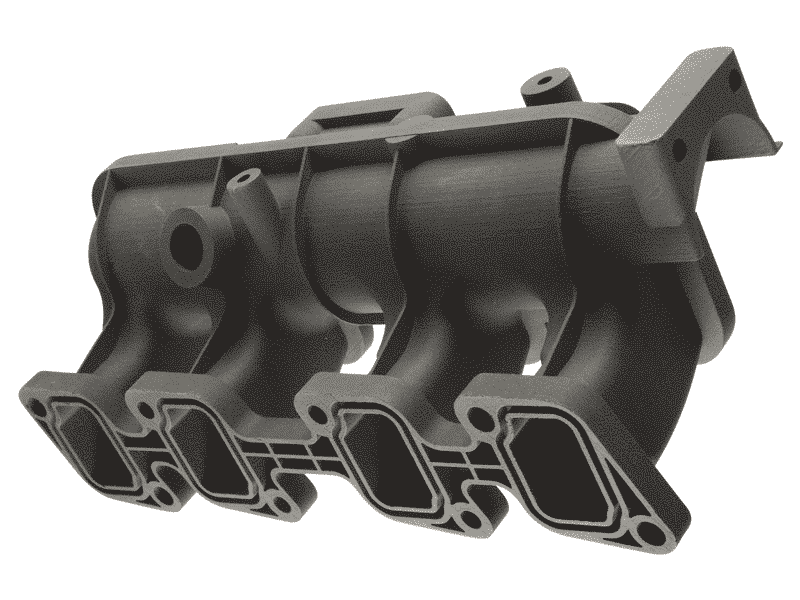

MJF PA12 with Glass Beads is filled with 40% glass bead particles and as a result, is a much stiffer material. The higher rigidity makes this well-suited for structural parts and housings that will remain stiff and strong over time. It will hold up better over time, specifically for applications that may be exposed to friction and wear, such as tooling and molds.

Selective Laser Sintering (SLS) PA11

In contrast to PA12 Glass Beads, SLS PA11 is the most flexible nylon material due to its much higher elongation at break. It also has a slightly higher strength than the other three materials. This combination of high strength and good elongation at break makes it the most impact-resistant material of the four choices. Popular applications include sports equipment, orthotics, and prosthetics, hinges (where high ductility is important). PA11 also has higher temperature resistance and is based on renewable resources, therefore making it more environmentally friendly.

Below is a table to directly compare material properties:

| Tensile Strength X-Y | Tensile Strength Z | Glass Transition Temp | Tensile Modulus X-Y | Tensile Modulus Z | Strain at break X-Y | Strain at break Z | Density | |

| SLS PA12(Versatile Plastic) | 48 MPa | 42 Mpa | 349 deg F | 1650 MPa | 1650 MPa | 24% | 4% | 0.93 g/ cm3 |

| MJF PA12 | 48 MPa | 48 MPa | 369 deg F | 1800 MPa | 1800 MPa | 20% | 15% | 1.01 g/cm3 |

| MJF PA12 w/ Glass Beads | 30 MPa | 30 MPa | 367 deg F | 2500 MPa | 2700 MPa | 10% | 10% | 1.3 g/cm3 |

| SLSPA11 | 48 MPa | 48 MPa | 396 deg F | 1600 MPa | 1600 MPa | 45% | 30% | 0.99 g / cm3 |