Compared with traditional production methods, metal 3D printing has the advantages of greater flexibility in design freedom, shorter R & D period, and fewer costs, thus enabling the production of thin-walled, irregularly curved surfaces, lattice structures and other parts which are hard or even impossible to produce by traditional machining processes.

The scope of FacFox’s metal printing services covers aeronautics and aerospace, educational research, industrial molding, energy and power, customized medical appliance, creative accessories, etc. The materials suitable for printing include titanium alloys, aluminum alloys, stainless steel, mold steel, precious metals, etc.

Q&A

What is the printing method we use?

SLM (Selective Laser Melting). It is in an additive manufacturing method specially developed for 3D Printing metal alloys. It creates parts additively by fusing metal powder particles together in a full melting process.

Unlike DMLS, SLM fully melts the powder, and therefore it needs to reach a higher temperature than this other metal 3D printing technique. The build chamber is filled with an inert gas (either argon or nitrogen at oxygen levels below 500 parts per million) in order to create the perfect conditions for melting.

The full melting process allows the metal to form a homogeneous block with good resistance. It fits perfectly for pure metals like titanium or aluminum. Because we need a higher temperature to fully melt the material, the cooling time will be longer than for DMLS.

How many metal materials we can offer?

- Titanium alloys: TA1,TC4

- Aluminum alloys: AlSi10Mg,AlSi7Mg

- High-temperature alloys: IN718(GH4169),Hastelloy X(GH3536),GH3230,CoCrWMo

- Stainless steel: 304L,316L,17-4PH,S130

- Mold steel: 18Ni300,H13

- Pure silver and pure copper

- Other special powders

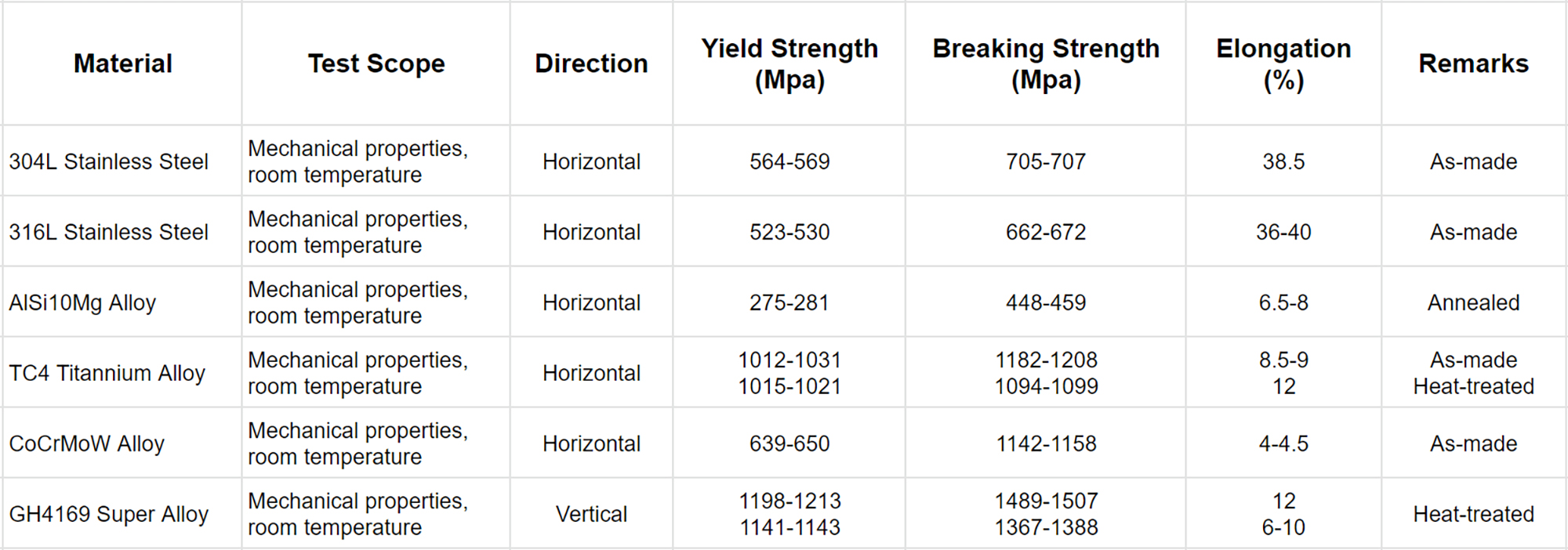

Mechanical Datasheet for Common Materials

What’s the printing capability?

We own three kinds of full-size metal 3D printers that are all stable and reliable with compact sizes and distinguished features. Based on Selective Laser Melting (SLM) technology, all three kinds of 3D printers can produce parts with high precision and excellent mechanical properties and better material utilization. The full series of equipment is driven by a world-class optical system and a servo drive with ultra stability and reliability.

Printer 1:

- Building Volume: Φ120mm×100mm

- Precision: ±0.02mm

- Laser Power: 200W or 500W

Printer 2:

- Building Volume: 250mm×250mm×300mm

- Precision: ±0.05mm

- Laser Power: 500W

Printer 3:

- Building Volume:500mm×500mm×1000mm

- Precision optics:±0.05mm

- Laser Power:500W or 1000W

What is the price of metal printing service?

The cost of metal prints consists of three parts: the operation & maintenance cost for 3D printer, material cost, and labor cost,. And as for our high-precision metal printing service, the price relies a lot on the machine rather than the materials. The operation & maintenance cost of the printer is affected by printing hours, which depends on the model itself.

As the cost of materials only occupies a small proportion of the total cost, the unit prices of maraging steel, aluminum, and SS304L are similar. The design of the model will impact the necessary supporting structure and further affect the consumption of materials. Besides, although the metal powders can be recycled, their mechanical properties have changed to some extent, thus they are not suitable to make some high-strength parts. The material you required also matters. For example, 316L has a better performance than 304L and is used more often, so if you want to print 304L products, you need to judge and weigh between the high start-up cost of the printer and the order value.

The complexity of your design will also result in different labor cost. Our specialists participate in the whole process, from the examination and optimization of the 3D model, to printing, post-processing, and quality checking process.

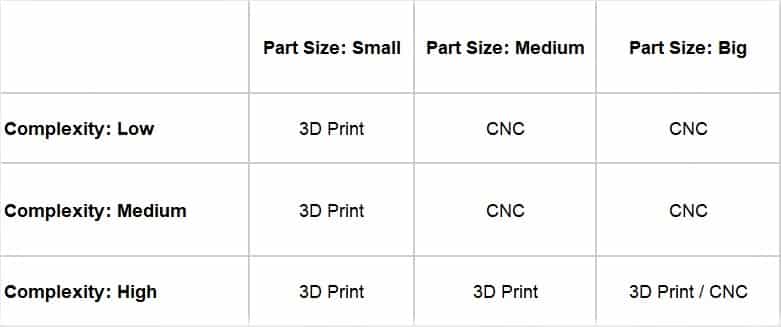

Is metal 3D printing superior to the CNC machining?

Metal 3D printing

- Suitable for parts with inner runner system, complex geometric structure, or lightweight requirement.

- Design in the software takes the place of creating physical tools.

CNC machining

- Suitable for processing heavy parts or highly accurate parts.

- Can achieve tighter tolerances as CNC machining does not need additional post-processing like ‘heat treatment and reprocessing’.

- Generally better for low-volume production if the geometry is manufacturable.

- Need special tools like undercut to create a right angle even in the case of five-axis machining.

For automotive, aerospace, and other high-precision products, the required tolerances of metal parts exceed the tolerances that 3D printing can provide. However, the design flexibility of 3D printing (usually used to reduce weight/enhance ergonomics) is exactly what these applications require. Using CNC machining on the basis of 3D printed parts can provide the best results. In some cases, tolerances can be as tight as ±0.005 mm.

Similarly, considering the fine surface treatment that requires tight tolerances, especially the parts that need to be accurately matched with other parts, we can use 3D printing to make a slightly larger part, and then adopt CNC machining, such as 5-axis milling, to meet the accuracy requirements.

Cases

Product Name: Preswirl Nozzle

Size(mm): φ400×80

Material: High-temperature alloys IN718

Printing Hours: 37

Note: This large-size complex curved blade surface was directly printed in one piece.

Product Name: Aeroengine Fan Blade

Size(mm): 310×350×724

Material: Stainless steel 304L

Printing Hours: 176

Note: It adopts topology optimization for internal design to reduce the structure weight. The height of the blade is 724mm which breaks through the technical limit of SLM construction and hits a new record in the industry.

Product Name: Hollowed Blade of the Final Turbine

Size(mm): 100×100×400

Material: Stainless steel 304L

Printing Hours: 49

Note: The hollow structure of the blade reduces the weight, and the surface is designed with drainage holes to prevent corrosion, which makes it hard to precisely manufacture with the traditional process.

Product Name: Blade with Lattice Structure

Size(mm): 78.7×75.8×44

Material: AlSi10Mg

Printing Hours: 7

Note: The internal lattice structure of the blade guarantees mechanical properties while greatly reducing the whole weight.

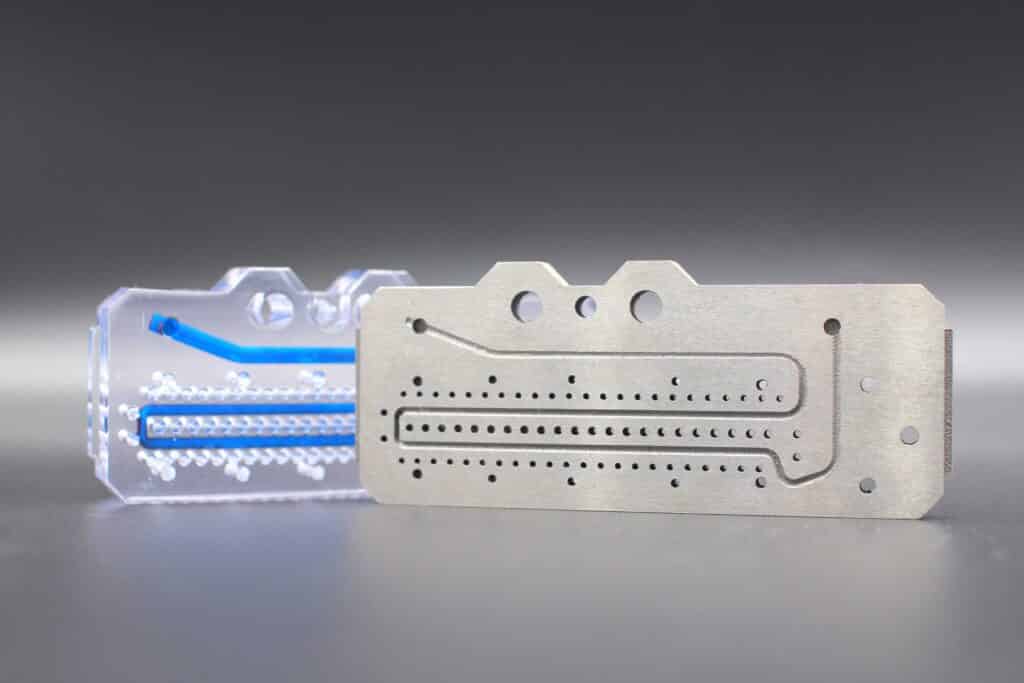

Product Name: Industrial Mold

Size(mm): 49.8×56×52.7

Material: H13

Printing Hours: 9

Note: It disrupted the traditional diffusion welding method and adopted the direct-print forming of the internal cooling waterway. The hardness of the printed part reaches 52HRC.

Product Name: Industrial Mold

Size(mm): φ32×276

Material: 18Ni300

Printing Hours: 16

Note: The internal complex waterway can be designed without limitation by the traditional processing method and the special-shaped waterway improves cooling efficiency.

Product Name: Blower Intake Section

Size(mm): 200×200×155

Material: Aluminum alloys AlSi7Mg

Printing Hours: 64

Note: Formed integrally. Compared with the traditional welding process, it better ensures the uniformity of the properties and positions of all blades, thus guarantees the stability of air volume and pressure in the intake section.

Product Name: Spiral Nozzle

Size(mm): 44.7×44×90

Material: GH3536

Printing Hours: 13

Note: The complex blade curved surface is directly formed, and the unique nozzle is designed with unobstructed flow channels to minimize liquid blockage and maximize the flow of liquid on a given size of the pipe.

Product Name: Turbine

Size(mm): φ210×53

Material: High-temperature alloys IN718

Printing Hours: 20

Note: Direct shaping of complex blade surfaces shortens the production time than traditional processing methods and is suitable for low-volume production.

Product Name: Bone Trabecular Structure

Size(mm): 19×26×115

Material: TC4

Printing Hours: 11

Note: The bone trabecular structure is realized by SLM technology, and the porosity can reach up to 80%.

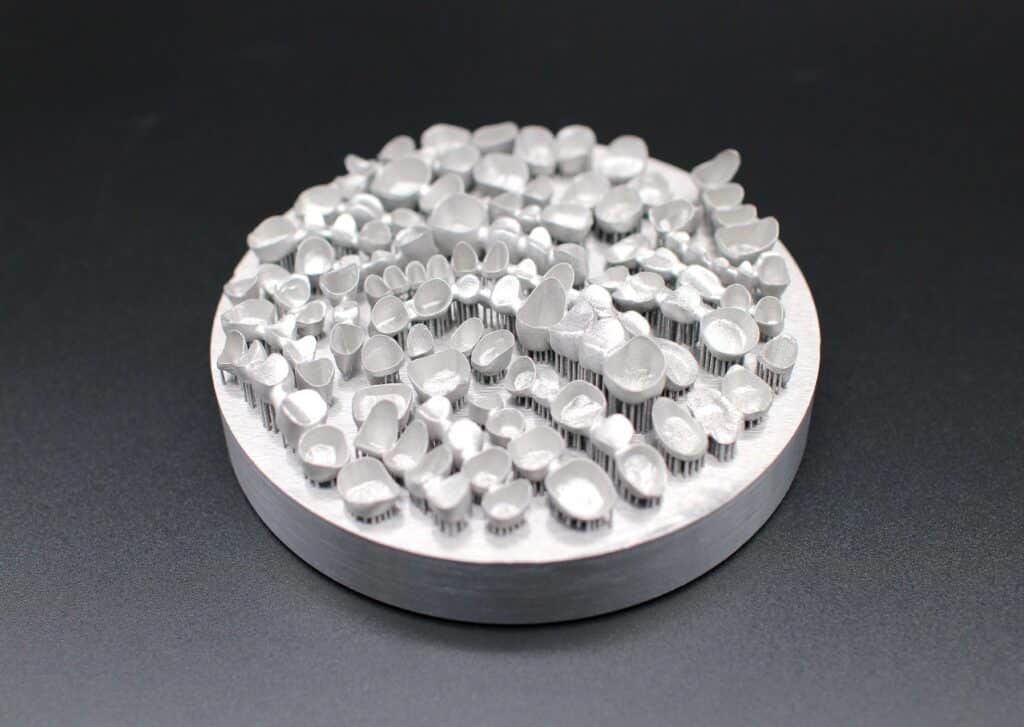

Product Name: Dentures

Size(mm): φ120×8

Material: CoCrWMo

Printing Hours: 5

Note: High precision and fast production realize rapid dental customization.

Product Name: Octopus

Size(mm): 96×112×155

Material: Stainless Steel 304L

Printing Hours: 6

Product Name: Chess

Size(mm): φ26×30-70(H)

Material: Stainless steel 304L

Printing Hours: 40 per set