Conclusion

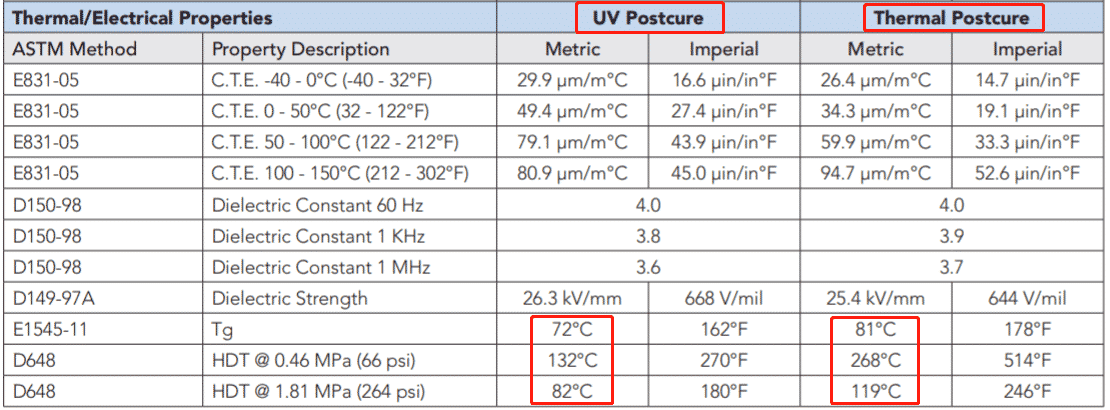

In many occasion, you will find there are 2 methods introduced in HDT(heat deflection temperature) of SLA resin, like this:

Apparently, thermal postcure will increase the HDT of resin material, so how do we conduct UV postcure and thermal postcure? Below is the example of our postprocessing procedure for Somos PerFORM SLA resin.

Postprocessing

Part-cleaning Procedure

- Drain excess material off the parts in the vat.

- Remove the platform from the machine and remove the parts.

- Wash the parts for 20 minutes in an automated parts washer, such as Ramco, or an ultrasonic cleaner. Please contact your machine’s manufacturer for use of recommended solvents.

- If needed, place the parts in an ultrasonic cleaner filled with non-volatile solvents, such as TPM or Propylene Carbonate, for 20 minutes. If excess material is still present after 20 minutes, repeat another 20 minutes in the ultrasonic cleaner.

- Drain parts, then rinse them with 99% isopropanol (IPA). Brush the parts with isopropanol. This removes the solvent, as well as any remaining excess material.

- Dry the parts with compressed air and place them in a well-ventilated area to allow all absorbed solvent to vacate the part.

Manual and Ultrasonic Cleaning

During a build, you may find that excess material builds up on flat surfaces and in cavities. There are two ways to clean these:

- If the surface is flat, simply scrape it with a spatula to remove any excess material. You can return the excess material to the vat prior to re-mixing.

- Cavities and tight angles that act as trap volumes can be cleaned using an ultrasonic cleaner. The excess resin can then be returned to the vat prior to re-mixing.

Post Cure Procedures

UV Post-cure

After thoroughly air-drying the parts and checking that they are free from liquid resin residue, UV post-cure the parts for 20 minutes, rotating the part once after 10 minutes.

Thermal Post-cure

To increase the heat resistance and tensile strength of parts made with Somos® PerFORM, we recommend you thermally post-cure them. Follow these steps to thermally post-cure your parts:

- Place the parts in a programmable oven and use the following cycle:

- Warm up: Raise the oven temperature above 160 oC and maintain this for 2 hours.

- Cool down: Ramp the oven temperature down to room temperature over 2 hours.