In the ever-evolving industrial manufacturing landscape, thin-wall metal printing technology is becoming a crucial force driving product innovation and performance optimization. Thin-wall structures, designed with thicknesses typically less than or equal to 1mm and sometimes reaching micron levels, offer significant benefits. These include reduced weight, improved heat dissipation, and minimized forming dimensions, enabling lightweight and efficient product designs.

FacFox’s Role in Thin-Wall Metal Printing

FacFox is at the forefront of promoting and applying thin-wall metal printing technology. Their advanced micron-level 3D printing technology can achieve metal thin-wall forming sizes as small as ≥30μm. This precision brings revolutionary changes to traditional fields such as aerospace, automotive manufacturing, and electronic devices, while also expanding into new applications like medical devices and precision molds.

Market Applications and Advantages

Thin-wall metal structures, characterized by their thickness being much smaller than their other dimensions, are widely used in engineering applications across power machinery, aerospace, and electronic devices. These structures offer several notable benefits:

- Lightweight Design: Reducing wall thickness significantly lowers the weight of components, facilitating lightweight product designs.

- Efficient Heat Dissipation: Thinner walls allow heat to be conducted to the surface more quickly, improving heat dissipation efficiency.

- Material Savings: Thin-wall designs reduce material usage while maintaining structural strength, lowering production costs.

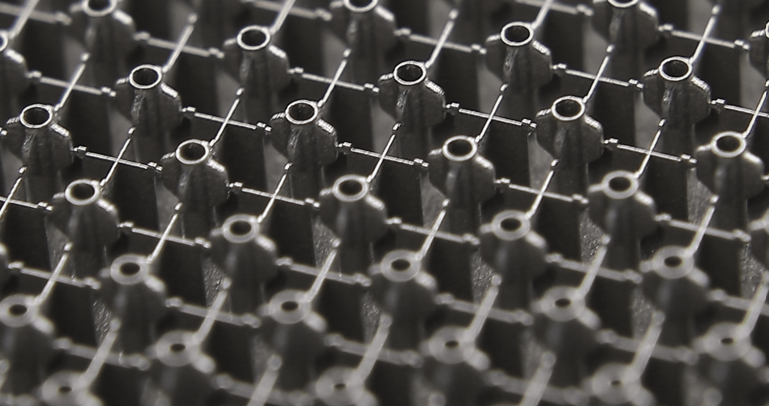

Case Study: Heat Sink Manufacturing

For example, a heat sink with dimensions of 15×30×30mm, printed using FacFox’s advanced micron equipment, features an inner wall thickness of just 0.1mm. This showcases exceptional manufacturing precision, with each thin-wall interval’s error uniformly controlled within 0.005mm. Such precision is crucial for enhancing heat dissipation efficiency and lightweight design.

Medical Applications: Spiral Pumps

In the medical field, spiral pumps are widely used. However, the unique structure of the pump body has always posed challenges in terms of processing difficulty and cost. Micron-level 3D printing technology offers significant advantages for processing pump body structures, such as lightweight pump bodies, thinner spiral blades, and more blade layers, greatly increasing work efficiency. Using different metal materials ensures both durability and fatigue resistance while enhancing efficiency and design flexibility. Smaller forming structures can promote the miniaturization of medical devices, providing more working space when inserted into the human body.

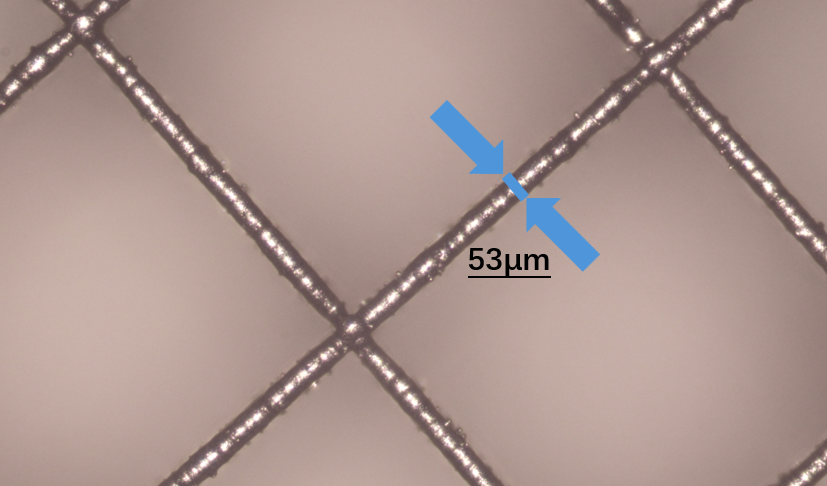

Micro-Links in Precision Printing

Moreover, micron-level thin-wall manufacturing technology is not only reflected in products but also plays a role in unseen areas. Micro-links, used in small-size precision printing, connect various products for better quality inspection and post-processing. These structures need to be small and thin to facilitate subsequent processing. For example, a micro-link with a wall thickness of just 60μm effectively achieves this, ensuring efficient and smooth post-processing without affecting the product.

FacFox’s Commitment to Excellence

FacFox is dedicated to full-scale laser additive manufacturing equipment and product manufacturing. Beyond conventional precision, the company boasts exclusive micron-level metal additive manufacturing technology, Micro-LPBF/SLM, which significantly optimizes the precision (≥2 microns), surface roughness (Ra≥0.8 microns), and enables support-free printing of various structures above 10 degrees.

Conclusion

Explore the future of manufacturing with FacFox’s advanced 3D printing services and unlock new possibilities for your products!