What are 3D Printed Benchmarks and Unit Tests?

In the world of software development, benchmarks and unit tests are essential for ensuring code quality and performance. Similarly, in 3D printing, we can leverage these concepts to enhance print quality and reliability.

Benchmarks

These are standardized 3D models designed to test specific aspects of a 3D printer’s capabilities. They can evaluate factors like layer adhesion, overhang performance, detail resolution, and overall print quality. Popular examples include the 3DBenchy and the Torture Test.

Unit Tests

Smaller, focused tests that examine specific components or features of a 3D model. They can be used to verify dimensions, tolerances, and how different parts fit together. By printing and analyzing these smaller sections, you can identify and address issues early in the design process.

Why are they important?

- Improved Print Quality: Benchmarks and unit tests help identify and rectify printer calibration issues, material inconsistencies, and design flaws.

- Time and Cost Savings: By catching problems early, you can avoid wasting time and materials on failed prints.

- Reliable and Consistent Results: Regular testing helps maintain consistent print quality over time.

- Optimized Printer Settings: Benchmarks can help fine-tune printer settings for specific materials and applications.

How to Implement Benchmarks and Unit Tests

Step 1: Select Appropriate Benchmarks.

Choose benchmarks that align with your specific printing needs and goals.

Step 2: Design Effective Unit Tests.

Create small, isolated test components that cover critical aspects of your model.

Step 3: Establish Testing Protocols.

Develop clear guidelines for printing, measuring, and evaluating test results.

Step 4: Analyze and Iterate.

Continuously analyze test results to identify areas for improvement and refine your printing process.

Popular Benchmark Models

3DBenchy

A small sailboat model that tests a wide range of printing parameters.

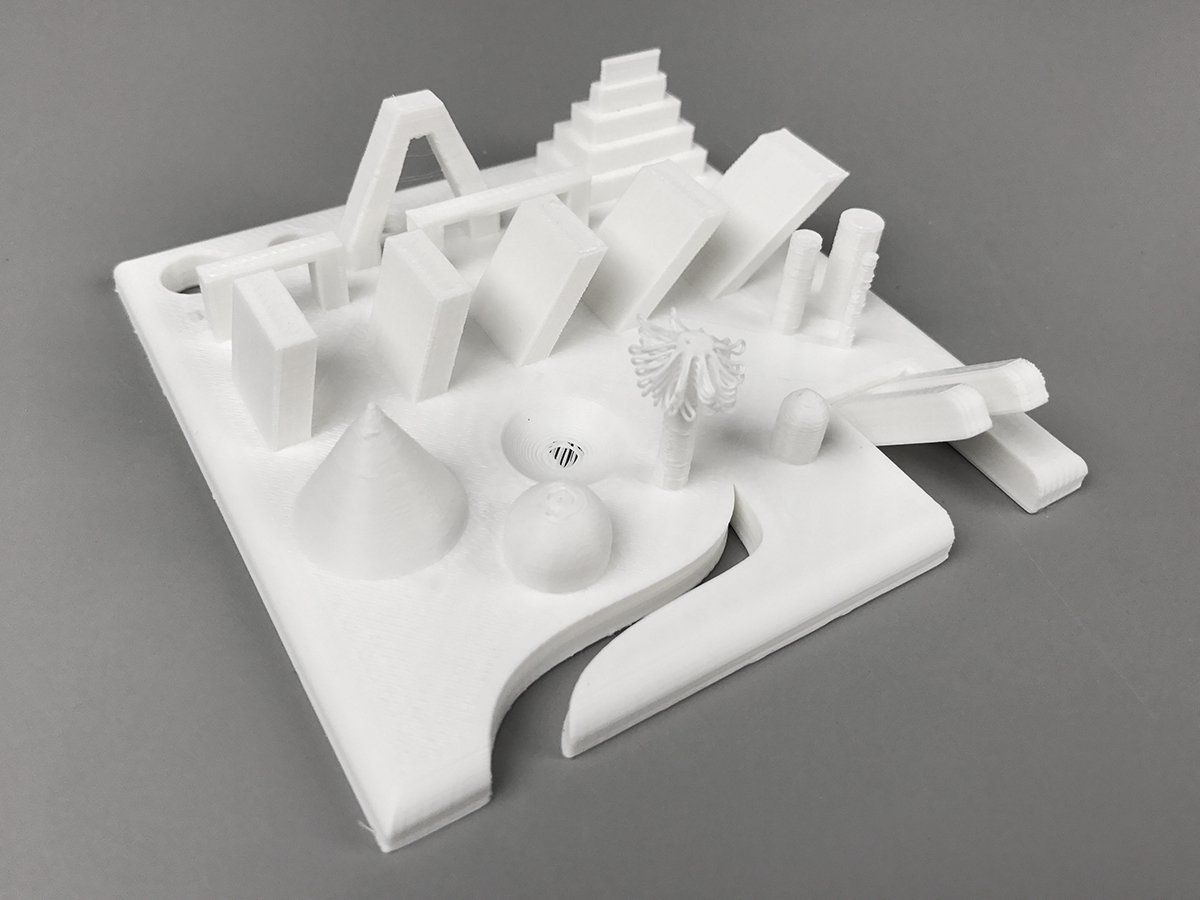

Torture Test

A complex model with intricate details to assess a printer’s capabilities.

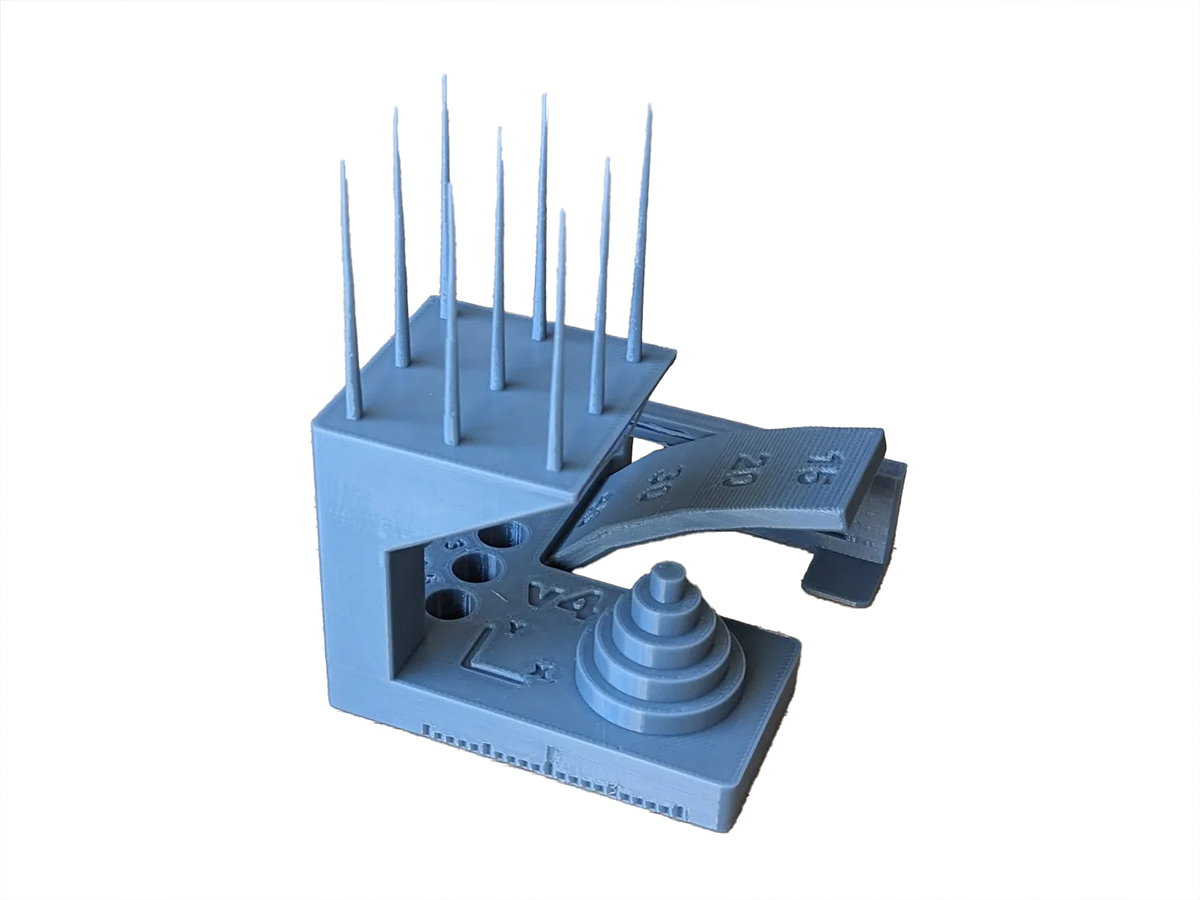

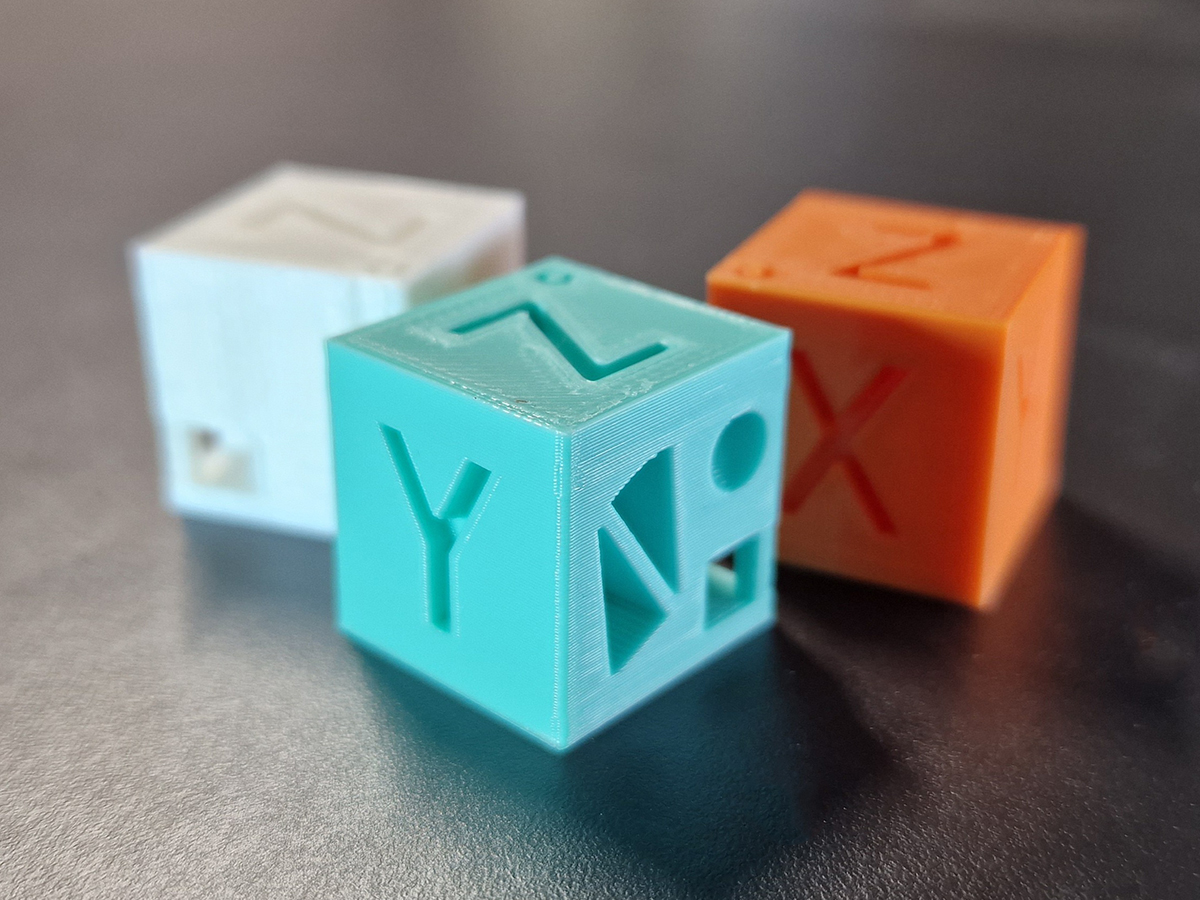

Calibration Cubes

Simple cubes with varying dimensions for checking dimensional accuracy.

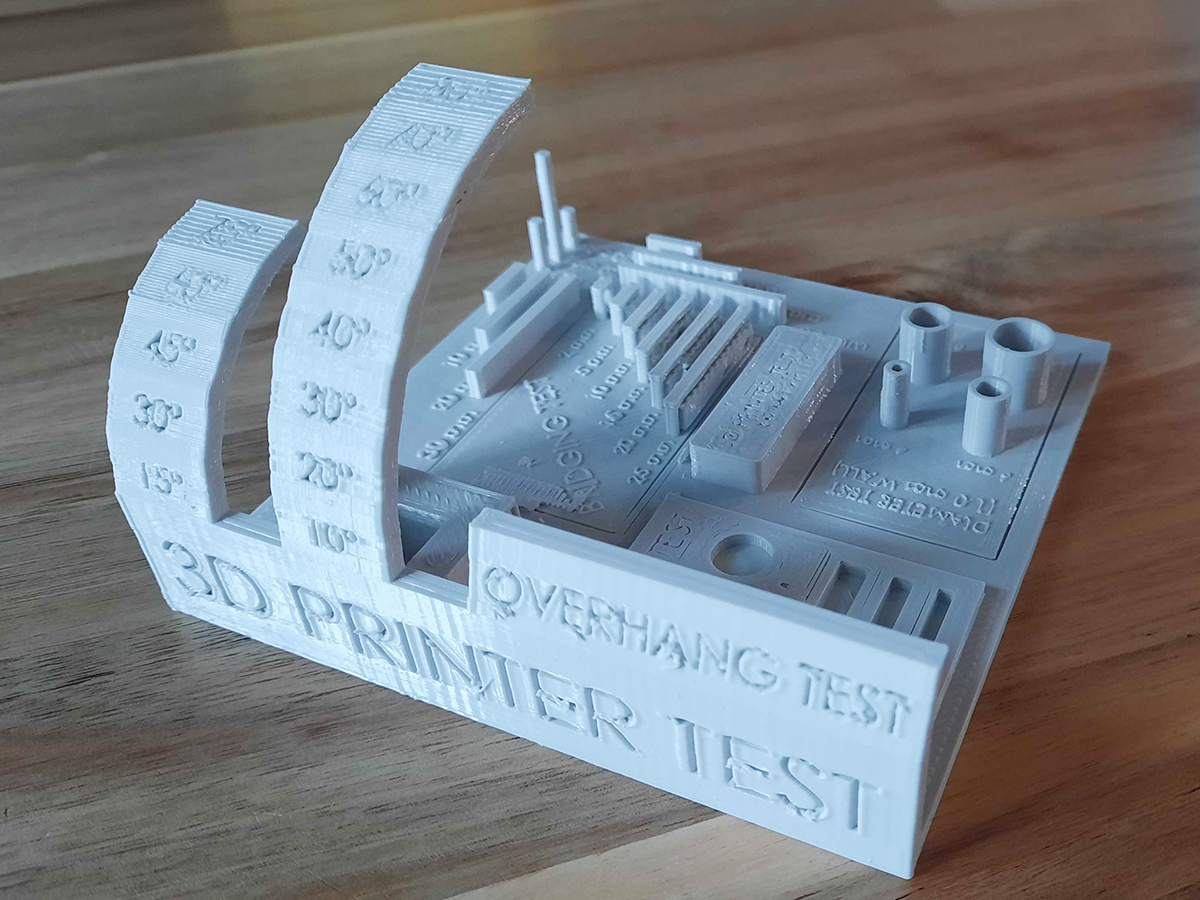

Overhang Test

Models with different overhang angles to evaluate overhang performance.

Related Insights

Benchmarking Different Printers

A study from 3DPrint discusses methods for comparing different 3D printers using benchmarks. It highlights that there is no standardized approach, and factors like filament diameter and nozzle size can influence results.

Designing for Unit Tests

An article from Markforged emphasizes the importance of designing for 3D printing using unit tests. Unit tests can be small, functional segments used to verify the printability and functionality of larger designs. This can help reduce costs and waste.

Strength Testing with Unit Tests

An article by EngineerDog explores using a homemade testing machine to analyze the strength of 3D printed parts. Unit tests can be applied here to create test specimens with specific geometries to assess the strength of different designs under load.

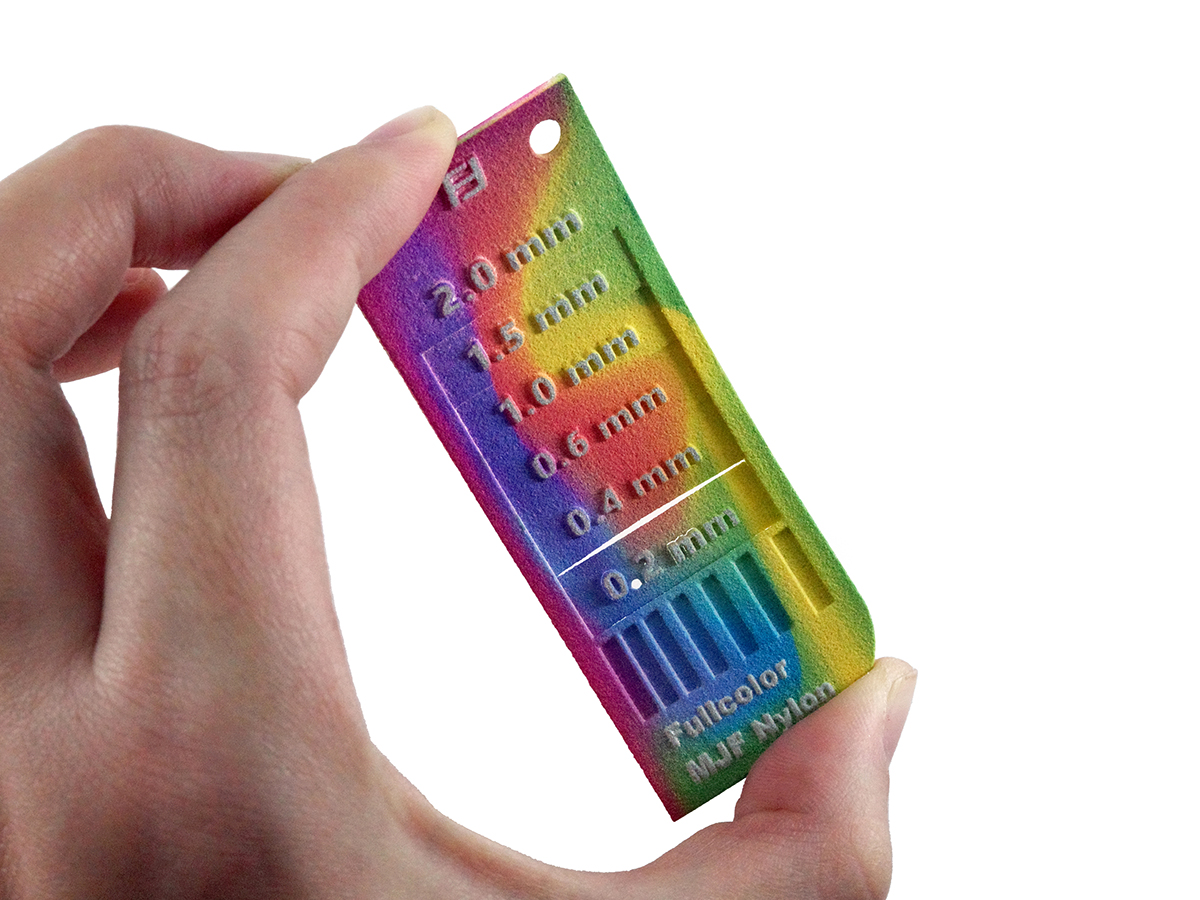

Unit Testing for Tolerances

MLC CAD discusses the challenges of determining tolerances for 3D printed features. Unit tests and benchmarks can be used to determine the manufacturing tolerances of your printer and refine specific dimensions in your designs. This can help ensure parts fit together correctly.

Let FacFox be your partner in print perfection

By implementing benchmarks and unit tests into your 3D printing workflow, you’re taking a crucial step towards producing high-quality, reliable parts. But navigating the complexities of 3D printing can be challenging.

With our advanced 3D printing technologies, expert team, and commitment to quality, we can help you bring your designs to life. From rapid prototyping to final production, we offer a wide range of services tailored to your specific needs.

Contact us today to discuss your project and discover how FacFox can help you achieve your goals.