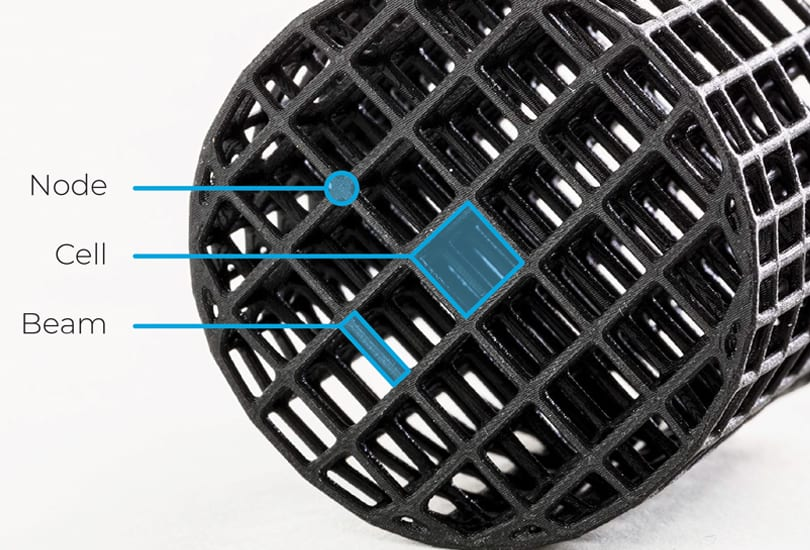

Additive manufacturing (AM) processes allow engineers to unlock the capabilities of lattice structures to enhance the performance of their products. Lattices are two or three-dimensional micro-architectures comprised of a network of nodes and beams, or struts, that dramatically reduce weight and retain structural integrity.

There are a myriad of lattice types available

There is a myriad of lattice types available that have unique characteristics (modes of deformation, material efficiency, etc.) and aesthetics. Many of these lattice structures are inspired by naturally occurring crystalline structures. And due to their inherently small features, lattices are difficult —or nearly impossible— to create through legacy manufacturing methods.

The incorporation of lattice structures allows engineers to explore more of the design space by re-thinking the desired performance of their part.

Through latticing techniques, the overall part mass can be reduced by 90% or more by precisely tuning the lattice parameters to the physical loads on the part.

Mechanical benefits

The benefits of lattices have been well-known throughout time. If you look close enough, you see lattices in nature (such as bone, metal crystallography, etc.) as well as modern architecture. Take the Eiffel Tower example: The metal structure of the tower efficiently supports its weight as it reaches into the sky. Similar to a simple lattice, this self-supporting structure is by volume, mostly air. The high strength-to-weight ratio possible with lattices enabled this tremendous architectural achievement.

Similarly, in product design, the mechanical benefits of lattices (e.g., high surface area, excellent shock absorption, impact protection) empower product designers to defy the constraints of traditional manufacturing to create new —and often higher-performing— products.

Good strength-to-weight ratio

There are generally two paths to improving the strength-to-weight ratio of a given part. Through traditional manufacturing, it is accomplished by reducing materials in non-critical areas to optimize material usage. Through latticing, you are able to remove material in the critical areas of part. Although latticing does reduce the overall strength of the part, the weight savings can improve this strength-to-weight ratio.

High surface area

Lattices are not only lightweight, but they unlock a large amount of surface area — a key benefit for products that facilitate heat exchanges and chemical reactions.

Consider heat exchangers used in computers in servers and data centers. Typically, the performance of the processor is limited by the amount of heat produced. The goal is to remove the heat from the chip and expel it into the atmosphere, usually aided by a fan. The overall efficiency of this system is linked to the amount of surface area on the heat sink (the piece of metal that pulls heat away from the chip). Lattices can dramatically increase the amount of surface area available or, alternatively, produce that amount of surface area more affordably by avoiding complex tooling procedures. In fact, this efficiency gain can be realized on many different types of heat exchanger applications, where small features with large surface areas are difficult or nearly impossible to create without additive manufacturing.

Excellent shock absorption and impact protection

Lattices can also aid in safeguarding products from drops or collisions by better absorbing impact energy. Lattices can either be integrated into a product —such as a football helmet— to reduce impact stress or used as a sacrificial feature to protect the critical components of a product. A lattice could, for example, be used around or inside electronic components to protect it from a dynamic event, such as an all-too-common accidental drop.

Desirable vibration and noise dampening

Additively manufactured lattices also give engineers a new way to eliminate mechanical noise — such as vibrations— which can be uncomfortable for users and even degrade machine performance.

Lattices are effective at dampening vibrations because of their low stiffnesses and ability to withstand and recover large strains. Lattices could, for instance, be integrated into an isolating pad on heavy equipment to reduce the amount of energy going into the manufacturing system. The tunable nature of lattices allows engineers to refine designs to match their particular application.

Unlock the potential of lattices by adhering to DFAM principles

It’s true that additive manufacturing can open up many new product opportunities, but there are design factors you need to acknowledge before printing a functional lattice. This is where design for additive manufacturing (DFAM ) steps in. DFAM helps design engineers to ensure their printed parts match the design intention.

- Cell structure

There’s a vast array of cell structures, which are the repeated unit in a lattice. The list of cell structures is very long and ever-growing. The most common cell structures include cubic, star, octet, hexagonal, diamond and tetrahedron, to name a few. Cell structures can be tuned and even mixed to get the desired response for your system, but your selection has implications. Some structures are more efficient (higher stiffness-to-weight ratios), others dampen energy better, and some are a little more aesthetically pleasing. The strengths and advantages need to be weighed against each other to make the right choice for your part.

- Cell size and density

Cell size and density refer to the size of an individual unit cell and how many cells are repeated within a space. The cell size itself depends on the thickness and length of its members and connecting nodes. Larger cells can be easier to print but can also act stiffer; likewise, smaller cells allow for more homogeneous system responses but are limited by feature sizes.

- Material selection

Your chosen material can define which lattice properties are possible. Elastomeric or soft materials generally require a smaller and denser cell population to reduce sag during printing. Alternatively, lattices printed with a more rigid material generally allow a greater design range with thinner members and larger cell sizes. - Cell orientation

The angle a cell is printed at can affect the success of a print because it influences the amount and placement of supports required. In general, a well-chosen and oriented lattice is self-supporting, which does not require separate supports. Oftentimes, a structure can be rotated to reduce supports. Think about a large cubic truss — if printed directly on the build platform, horizontal members will be unsupported. However, if the structure is simply rotated 45 degrees, the members are now self-supporting.

A lattice’s repeated unit cells open the door for countless sizes, shapes and performance attributes. The inherently complex nature of lattices makes them nearly impossible to create any other way than additive manufacturing.

If you’ve never designed with lattices before, it can be good to tap an expert who can help you get started. At FacFox, our team specializes in maximizing the total value of additive, from developing better-performing products with lattices to driving supply chain efficiency through on-demand production and virtual warehousing. To learn more about the potential value of additive —or to begin designing a product for AM processes— reach out to us today.