Learn what to look for in today’s best dental 3D printers and start producing your own dental models, dentures, surgical guides, clear aligners, and more.

Today, 3D printing is revolutionizing the practice of dentistry. Not only can procedures that once took weeks, now take just hours with chair-side production of dental models and surgical guides, but putting local dentists in full control of their patient-specific products – including night guards, temporary crowns, and dentures – means that there’s fewer appointments needed, vastly lowered costs, and improved patient care.

Let’s take a look at the growing selection of solutions that can bring your practice or lab into the era of digital dentistry.

Know Your Needs

As a dental practitioner or a specialist in a dental laboratory, you know that there’s a world of difference between dental models for patient education and dental parts for patient use.

If your goal is to print reasonably accurate models of a patient’s mouth taken from an oral 3D scan or impression in order to, for example, explain a procedure to a patient, then there’s no need for a specialized dental printer. In fact, you have a much wider range of printers to choose from for model making than you do for printing parts that will come in contact with a patient.

Nearly any resin printer – and many of the better filament printers – are capable of printing great dental models. Check out this printer guide:

How Are Dental Parts 3D Printed?

To illustrate how the components in digital dentistry work together, here’s a quick overview of the workflow to make a patient-specific dental night guard in-office.

It starts with the digital scan of the patient’s mouth with a hand-held intraoral scanner, external scanner, or the scan of a traditional plaster dental cast or model.

From there, your digital images are uploaded to computer aided design (CAD) software specific to the dental industry, such as Exocad or the software that comes with your 3D printer. There’s a wide range of dental CAD programs that will integrate with most major 3D printer brands. Choose the software that best matches your (and your staff’s) skill level.

Next, if your dental software doesn’t do this automatically (and most do), you’ll upload your design files to “slicer” software that either comes with your printer or is compatible with it. The slicer transforms your digital model into 3D printing instructions for the printer.

Once your night guard is printed in certified biocompatible resin, it requires some cleaning to remove any residue, removing the supports, and curing in light to harden fully. The last step is typically some polishing and it’s ready for the patient to try on. Depending on your printer, the entire process could take a few hours.

Criteria for Top Dental 3D Printers

Your choice of printer for biocompatible dental parts depends on a variety of factors including what you intend to print, how much you intend to print per day or week, how fast you need your parts, your budget, and how automated or easy-to-use you want the process to be. Are you just getting started or are you expanding or upgrading your operations?

You’ll also want to consider the level of service and support from your manufacturer and which dental software the printers are compatible with. Most manufacturers will send you a sample print, so be sure to request one to evaluate whether it meets your expectations for details, surface finish, and strength.

When asked to rank key purchase criteria for selecting the 3D printer brand their lab uses most, dental pros responding to a survey by printer manufacturer Carbon, said: accuracy, reliability and maintenance, return on investment, total cost of ownership, quality of materials, and lowest price topped the list.

Let’s take a detailed look at the top digital dentistry solutions in the industry. All of the printers on our list offer biocompatible materials. Scroll to the bottom for a look at materials and post-processing equipment.

| Brand | Print Types | Printer | Technology | Price Range |

|---|---|---|---|---|

| Stratasys | Models, surgical guides, night guards, castable partial denture frameworks, try-ins for veneers and dentures, orthodontic appliances, custom trays | J5 DentaJet, Objet30 Dental Prime, Stratasys J700 & J720 Dental, Origin One Dental | PolyJet, Digital light processing (DLP) | $100,000-$250,000 |

| SprintRay | Models, surgical guides, custom night guards, crowns, copings, bridges, RPDs | Pro95, Pro55 | Digital light processing (DLP) | $6,750 |

| Desktop Health EnvisionTEC | Models, surgical guides, provisional restorations, removable partials, wax-ups, temporary crowns and bridges, castable parts | Envision One, VECTOR 3SP, VIDA, D4K Pro | Digital light processing (DLP), Continuous Digital Light Manufacturing (cDLM) | $10,000 – $50,000 |

| Rapid Shape | Models, surgical guides, provisional restorations, removable partials, wax-ups, temporary crowns and bridges, castable parts | D10, D20, D30, D40, D70, D90 | Stereolithography (SLA) | $10,000 – $50,000 |

| Asiga | Models, dental orthodontics, crown and bridge, surgical guides, custom trays, partial dentures, clear dental splints, castable parts for crown and bridge and frameworks | MAX series, Pro 4K | Digital light processing (DLP) | $9,000 – $25,000 |

| Kulzer | Night guards, custom impression trays, surgical guides, models, CAD-to-cast structures | Cara Print 4.0 | Digital light processing (DLP) | $15,000 – $20,000 |

| Formlabs | Models, aligners, surgical guides, occlusal splints, denture bases, denture teeth | Form 3B, Form 3BL | Low-force stereolithography (LFS) | $4,000 – $14,000 |

| Zortrax | Patterns for crowns and bridges, clear aligners, surgical guides, occlusal splints | Inkspire | Stereolithography (SLA) | $1,700 |

| Carima IMD | Models, surgical guides, provisional restorations, removable partials, wax-ups, temporary crowns and bridges, castable parts | IMD | Digital light processing (DLP) | $12,000 |

| 3D Systems | Models, denture bases, castable parts, custom trays, surgical guides, orthodontic splints, crowns and bridges, removable frameworks, crown and bridge copings | NextDent 5100, ProX DMP 200 Dental | Digital light processing (DLP) | $ 5,000 – $ 10,000 |

| Shining 3D | model, wax-ups, surgical guides, gingiva, customized impression trays, bracket transfer trays | AccuFab-D1s, AccuFab-L4D | Digital light processing (DLP) | $3,000 – $5,000 |

| Carbon | Models, denture bases, carded teeth, splints, night guards, surgical guides, temporary crowns and bridges, trays, gingiva masks | L1, M2, M2d | Digital Light Synthesis (DLS) | $50,000 – $100,000 |

| Nexa3D | models, surgical guides, gingiva, customized impression trays, bracket transfer trays | NXD 200 | Stereolithography (SLA) | $30,000 |

| GE – Concept Laser | Metal bridges and crowns | mLab | Direct Metal Laser Melting (DMLM) | $250,000 |

| Trumpf | Metal bridges and crowns | TruPrint 1000 | Selective Laser Melting (SLM) | $170,000 |

Stratasys is a global player in 3D printing, with a major focus on the dental care industry. The company offers a range of industrial PolyJet multi-material printers ranging from the J5 DentaJet to the J700 Dental for large laboratories.

The multi-color, multi-material J5 DentaJet launched in 2021 is for customers looking to print high volumes of accurate dental models. Unique on our list, the J5 DentaJet can print soft and hard materials at the same time. For example, you could print a rigid opaque model , a soft gingiva mask, and a biocompatible transparent surgical guide all at the same time.

The J5 DentaJet comes with a full range of biocompatible dental resins, including a clear, flexible one, VeroGlaze opaque white for temporary in-mouth placement, VeroDent PureWhite, CMY resins for color, and a clear resin. Additionally, the Separator digital material coats dental models automatically in order to simplify the process of separating the acrylic device from the model, and then removing the wax and residue.

Also new from Stratasys in 2021 is the Origin One Dental 3D printer using a type of DLP technology called, Programmable PhotoPolymerization. Stratasys acquired Origin in 2020. Stratasys is one of the only company to offer multiple 3D printing technologies to dental labs.

SprintRay only makes dental 3D printers. In September 2020, SprintRay introduced its latest Pro55 ($6,750) dental 3D printing system to its range of 3D printers. Its high resolution makes it perfect for jobs that require razor-thin margins, such as direct restorative work, hybrid implant dentures, and cast applications, the company says.

In June 2021, SprintRay launched NightGuard Flex material for comfortable night guards. The material achieved FDA 510(k) clearance in December.

The company’s cloud-based design and treatment management software can guide you right from the planning stage through the post-processing.

Using third-party CAD/CAM treatment-planning software and SprintRay Pro, dental professionals can design and 3D print surgical guides in a little as 30 minutes, responding quickly to patient needs, the company says.

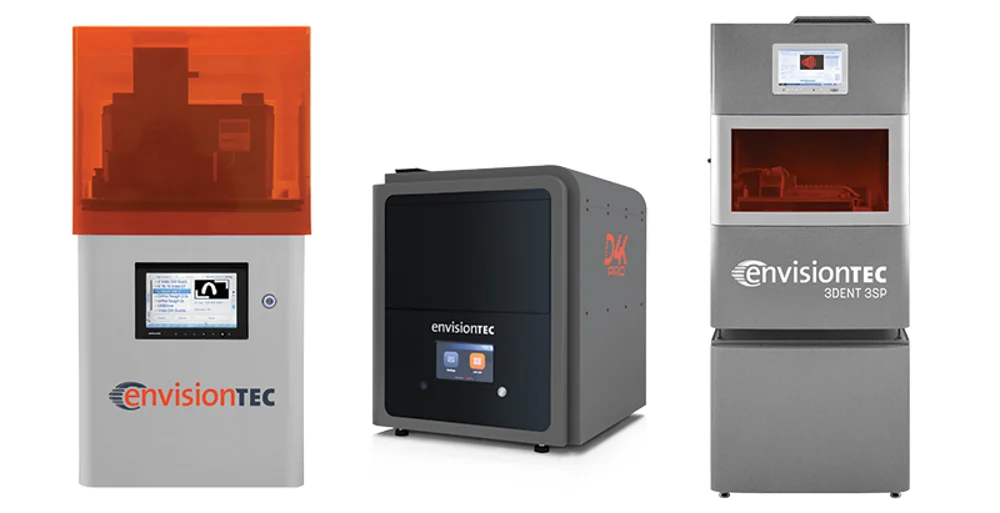

EnvisionTEC offers dental labs the full suite: a range of desktop, full-production, and high-speed continuous 3D printers. They’ve been in the dental industry since 2008. Paired with an extensive materials library, featuring a variety of FDA- and CE-approved biocompatible materials, EnvisionTEC printers can produce a wide range of dental appliances.

EnvisionTEC’s digital light processing (DLP) resin printer technology allows a variety of materials to be processed on the same machine. For example, the Vida desktop can print models, castables, and restorations.

The manufacturer offers a software-agnostic platform meaning they’ll work with whichever dental design solution you use, whether it is 3Shape, Dental Wings, or any other.

EnvisionTEC boasts a full-service training and support program, which includes on-staff certified dental technicians.

In early 2021, EnvisionTEC was acquired by another 3D printer manufacturer, Desktop Metal, that seems to be spinning off all medical-related printers to its new arm called Desktop Health. So far it seems Desktop Metal is offering the same EvisionTEC printers and services. Considering the massive financial backing of Desktop Metal, this new targeted focus on the medical industry can only benefit existing customers.

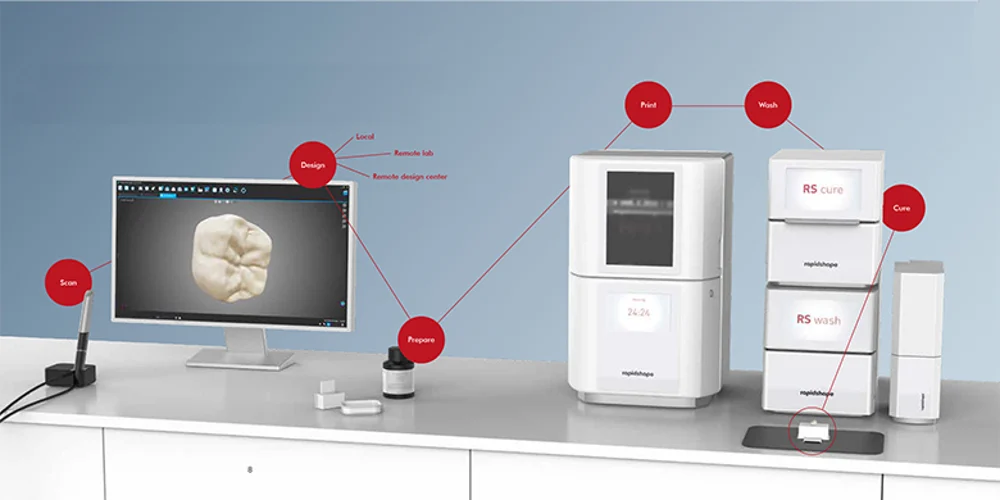

Rapid Shape

Rapidshape offers a wide array of desktop printers for dental offices and large production printers for dental labs. The smaller office printers, such as the D10+ and D20+, enable onsite 3D printing without specialist knowledge, the company says.

The D20+ features a mess-free resin cartridge and reservoir, but can be upgraded to an open material system. The larger and more feature-rich D3, D40, D70, and D90, offer dental labs more speed and automation.

In addition to its proprietary materials, Rapidshape partners with known material manufacturers, such as Dreve and Keystone Industries to offer a range of biocompatible resins.

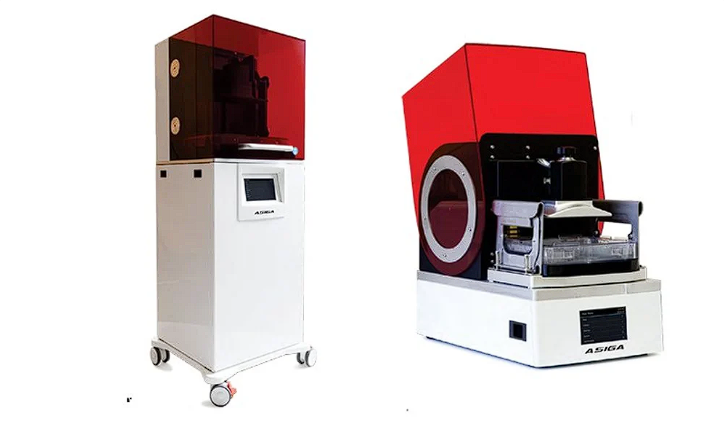

Asiga

From restorative dentistry through to orthodontic and prosthetic devices, Asiga 3D printers boast repeatable accuracy for production continuity and patient safety.

Asiga’s open material system provide compatibility with over 350 materials from the world’s leading material manufacturers for maximum flexibility and productivity.

The Aisga PRO2 can connect with a range of computer operating systems and 3D model file formats, including exoprint from exocad and 3Shape Implant Studio. The integrated PC can manage multiple builds at the same time, and offers a range of user-friendly features, as well as a lifetime of free software updates.

Kulzer

Kulzer is one of a handful of dental product suppliers to branch off into 3D printers. The company’s Cara Print 4.0 is billed as an economical method of producing polymer-based dental appliances in-house. Not only does it provide a cost-effective alternative to milling for certain indications, it is more competitively priced than other 3D printers on the market, while still meeting all the accuracy requirements, the company says.

The Cara Print 4.0 automatically adapts print speed according to the accuracy requirements of the current layer, often reaching speeds in excess of 100 mm/hour. The ability to vary layer thickness means that you can select the optimal balance of accuracy and speed. This makes it possible to optimize the process for appliances that don’t have high accuracy requirements (e.g. impression trays) by increasing the layer thickness and thereby reducing build time.

The printer software works with the CAD software of your choice, such as Cara CAD , Dental System (3Shape), DentalCAD (exocad) or DWOS CAD (Dental Wings).

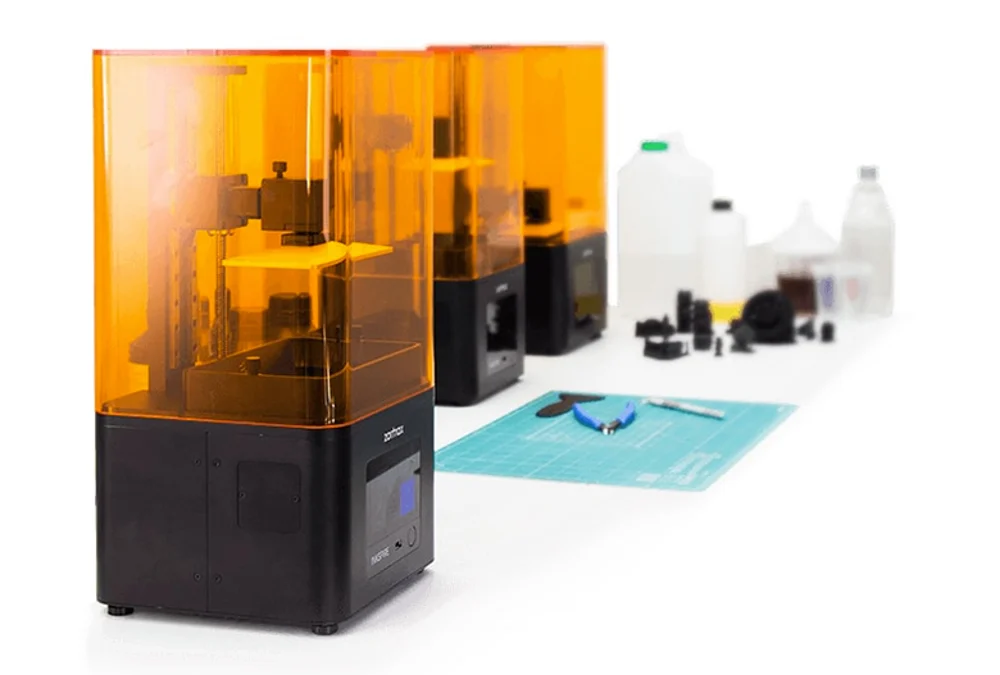

Formlabs

Formlabs introduced a new larger version of its popular Form 3B resin printer in Sept. 2020, the Form 3BL, that can print 24 models per print in about 10 hours. The more compact Form 3B can print 7 models per print in about 5 hours. “The Form 3BL is ideal for dental labs looking for a robust, production-ready printer,” the company says.

Both printers feature Formlabs own low-force stereolithography (LFS) technology that prints fine-detailed parts at a 100-micron resolution.

Formlabs also updated its PreForm software so that aligner models and restorative models now print 25% to 35% faster on the Form 3B than before. In 2021, Formlabs announced the new Scan to Model feature in their PreForm software, which will directly convert oral scans into printable models. Scan to Model will help dentists with limited CAD experience print their own models in-house.

Zortrax

The Zortrax Inkspire is a resin printer the company boasts as a plus-and-play device with an interface that makes it easy to operate even without prior 3D-printing experience. Appliances, including dental crows, bridges, and surgical guides, can be 3D printed directly with Zortrax’s own biocompatible resins or a range of compatible third-party materials. Castable resins are available for making investment patterns for casting dental alloys.

Accompanying the hardware is Zortrax’s own software, Z-SUITE, which is a dedicated slicing and 3D-printing farm (multi-printer) management software that comes free with every printer. Z-SUITE is compatible with popular dental CAD/CAM software solutions including inLab CAD SW 18 and ZFx Dental CAD Design Software. Zortrax Inskpire can also work with third-party slicers.

Carima IMD

Carima is the leading dental specialists in South Korea offering dental 3D printing solutions, including dental resins, and curing hardware. They offer a practical, same-day digital workflow solution centered around their IMD dental 3D printer and dedicated curing station.

The Carima IMD 3D printer is specially designed for dental and medical applications. Carima uses DLP (digital light processing), a sub-type of stereolithography technology that involves curing a liquid resin. This technique is faster than laser-based stereolithography, in which a laser selectively solidifies resin spot by spot.

Carima provides a range of CE-certified and FDA-approved materials for all use cases. Nonetheless, its open parameters enables users to work with all kinds of third-party resins.

The printer is relatively lightweight and works silently to offer discrete chairside operation.

For larger production of dental parts, Carima offers the DM400A 3D printer with a unique take on DLP, the company says is faster and cheaper. An entire build plate with, for example, 57 dental pieces, can be printed in just over an hour and a half. It can also 3D print larger, heavier parts because of its top-down DLP configuration.

From entry-level dental 3D printers and mid- and large-platform batch 3D printers, 3D Systems offers a selection of digital dental solutions that include materials and software.

The company’s NextDent 5100 printer is for high-speed 3D printing for production of dental appliances and castings. It is compatible with 30 proprietary biocompatible materials that are now available in several colors and shades to suit the dentition and gums of each patient.

Fully compatible with industry-standard intra-oral scanning and software solutions, the NextDent 5100 delivers precise results with minimal human intervention, the company says. Combine the printer with other 3D Systems dental solution components to create a comprehensive workflow. This includes the NextDent LC-3DMixer for optimal stirring of materials and the NextDent LC-3DPrint Box for UV post-curing.

Shining 3D

Chinese company Shining 3D – probably best known for its 3D scanners – is another company offering a fully integrated 3D digital dental solution from obtaining 3D data with 3D scanners for lab and intraoral 3D scanners for clinics, then designing with professional dental CAD software, to printing dental products, including working models, orthodontics models, implant models, surgical guides, wax-ups, and partial frameworks.

The company’s DLP 3D printer AccuFab-D1s offers users an intuitive and user-friendly workflow with fast print speeds and high accuracy. With diverse resin material options, it can meet demands in restorative, implant and orthodontic applications. Featuring a large build volume and a print speed of up to 50mm/h, the AccuFab-D1s is able to print 4 arch models in an hour and multiple surgical guides in less than 30 minutes.

In late 2021, Shining 3D introduced the AccuFab-L4D Dental.

Carbon

Carbon is unique among resin printers because of its proprietary Digital Light Synthesis (DLS) technology that combines high-resolution with rapid printing. Dentists in Carbon’s case study report being able to create full dentures in as little as 24-hours.

Carbon’s software is compatible with leading CAD/CAM software for dental practices and labs, such as 3Shape, exocad, and AvaDent. Materials from Carbon include FDA-approved resins for dental splints and night guards, and the company has initiated a program to develop a fully recyclable resin for dental models.

The larger L1 printer is a production solution for clear aligner models.

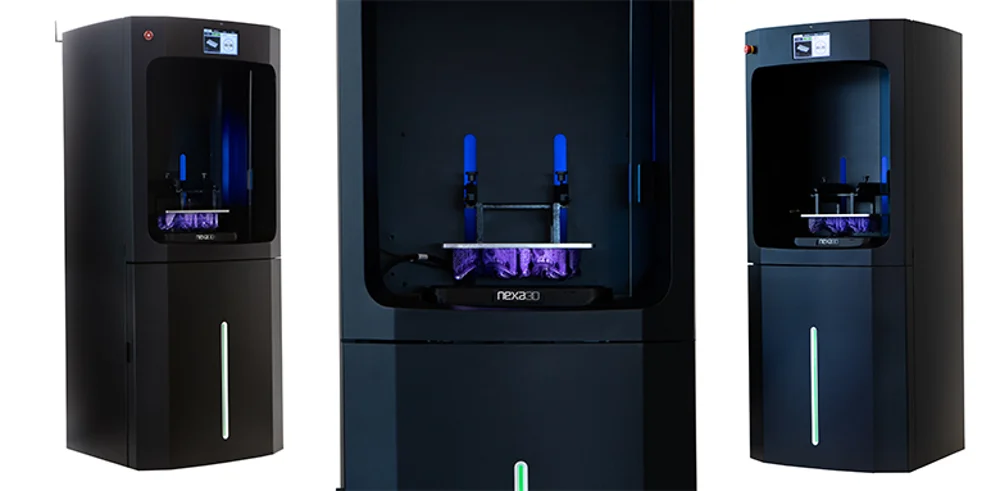

Nexa3D

Introduced in April 2021, the NXD200 from Nexa3D is designed specifically for dental applications. This is not your starter dental printer, but instead is aimed primarily at dental labs looking for high-throughput polymer production capabilities.

Nexa3D also partnered with dental materials developer KeyStone Industries to offered a full suite of specialist 3D printing resins, including the certified KeySplint Soft and KeyModel Ultra for dental and orthodontic models, as well as the KeyGuide and KeyTray materials for surgical guides and custom impression trays.

Like Nexa3D’s other resin printers, the new NXD200 has a fast printing engine, a 4K resolution LCD screen to deliver clinic-ready dental parts at a pixel pitch of just 76.5 microns. The company has also designed the NXD200 to be modular, so you can interchange parts and integrate hardware upgrades to eliminate obsolescence.

On the software side, the system is fully compatible with the company’s NexaX ‘file-to-part’ software for streamlined part preparation and remote print management.

GE – Concept Laser

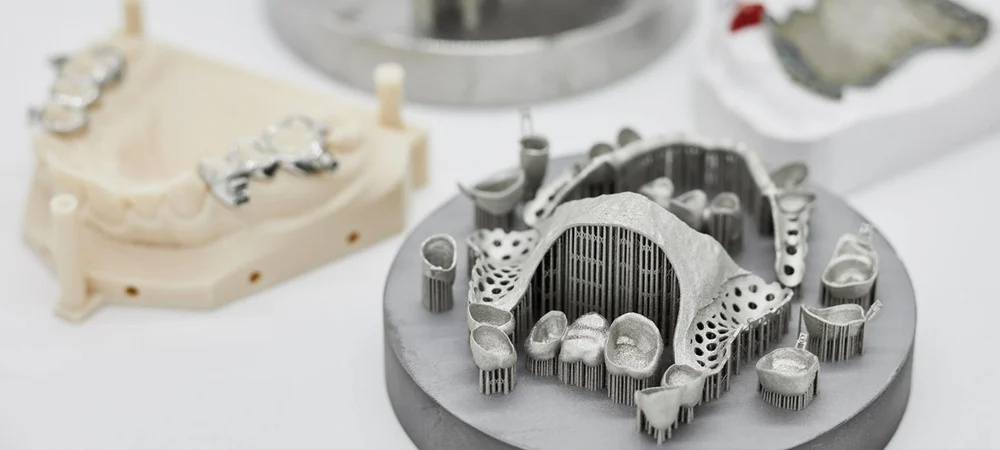

GE’s industrial Mlab and Mlab R are metal 3D printers used by dental labs to manufacture complex, customized, precise frameworks and tension-free dental prostheses. The Mlab printer uses metal powder (powder bed fusion technology) including stainless steel and gold, to print highly detailed and accurate oral implants.

GE promotes this metal method as an alternative to milling or in conjunction to milling metal dental parts because it says milling alone wastes up to 85% of material used in the manufacturing process. 3D printing is also faster than metal casting, with 99.6% density of the final product.

GE’s Dental Hybrid Manufacturing solution is in partnership with Follow-Me, Datron, and Fresdental milling machines, and combines the advantages of 3D printing with subtractive technology with one software to manage both the 3D printer and the milling machine.

Trumpf

The TruPrint 1000 from German manufacturer Trumpf produces a wide range of metal (including precious metals) dental parts and tools. It’s widely used in large dental labs looking for high volume production.

With the TruPrint 1000, Trumpf offers one of the most productive 3D printers for the dental sector for the creation of dental prostheses. There’s even more: your digital connection with milling stations is another highlight. This facilitates new and highly precise dental products.

MATERIALS

Although several manufacturers claim to have the broadest menu of materials, most printers will work with a wide range of third-party materials from reputable makers, including NextDent, Dentca, and KeyStone.

Many printer manufacturers work in conjunction with these material manufactures above to brand their own resins with properties that match the demands of their specific printers. But not all resins are interchangeable. Your printer will come with a list of tested and validated brands. If you use a material outside of this list you may not achieve the print quality or speed that’s typical of your printer.

Of course, any material for use in a patents mouth must be certified biocompatible in your region (by the FDA, CE, etc.). In addition to this certification, look for materials that meet ISO (International Standards Organization) levels for impact, strength, fracture-resistance, and stain-resistance.

POST PROCESSING EQUIPMENT

Prints do not come out of the printer ready to use. Washing, hardening, and surface-finishing are steps most dental products will need to move from raw print to final part. Factor these accessories into you digital dental budget plan.

Although a dunk in a simple dish of isopropyl alcohol (IPA) may suffice for washing most prints and curing could be done with sunlight or an inexpensive UV lamp, for interoral parts, a closed, automated approach is cleaner and more efficient.

Several printer manufacturers offer the washing and curing equipment necessary for final parts. Buying your accessories from the same manufacturer as your printer ensures easy integration, but you’re not locked in. Many accessory brands are interchangeable. The more sophisticated your printer, the easier the wash and cure process is, and many industrial printers incorporate printing, washing, and curing into a single unit.

Part Washing Accessories

The liquid solution you wash your prints with, and for how long, depends on your materials. Each type of print you make may have slightly different washing requirements.

The new SprintRay Pro Wash/Dry (available now for pre-order) is a fully-automated two-stage wash and dry system that promises finished parts in 10 minutes. Thanks to a suite of automatic features, the only time you have to touch IPA is when you pour it into the reservoirs. The unit comes with precalibrated hydrometers that sink in clean IPA and float when it’s dirty. So you always know when it’s time to refresh your IPA.

Zortrax offers an Ultrasonic Cleaner ($375), that uses high frequency sounds propagated in liquid detergent to remove excessive resin from parts 3D printed on the Zortrax Inkspire.

Part Hardening Accessories

Most resin printed parts come out of the printer only partially cured and require more exposure to UV light to fully harden. Curing boxes of various sizes provide uniform 360-degrees of light in a controlled environment. One example, the Rapidshape RS Cure, for example, uses powerful LED lights in combination with heating and a vacuum. This curing box is equipped with a wireless data link to the 3D printer so the right curing program is pre-selected for the part that was just printed.

Although some curing boxes have extra bells and whistles for convenience, most of them are so similar that many printer brands don’t even make their own and will point customers to a range of suitable options.