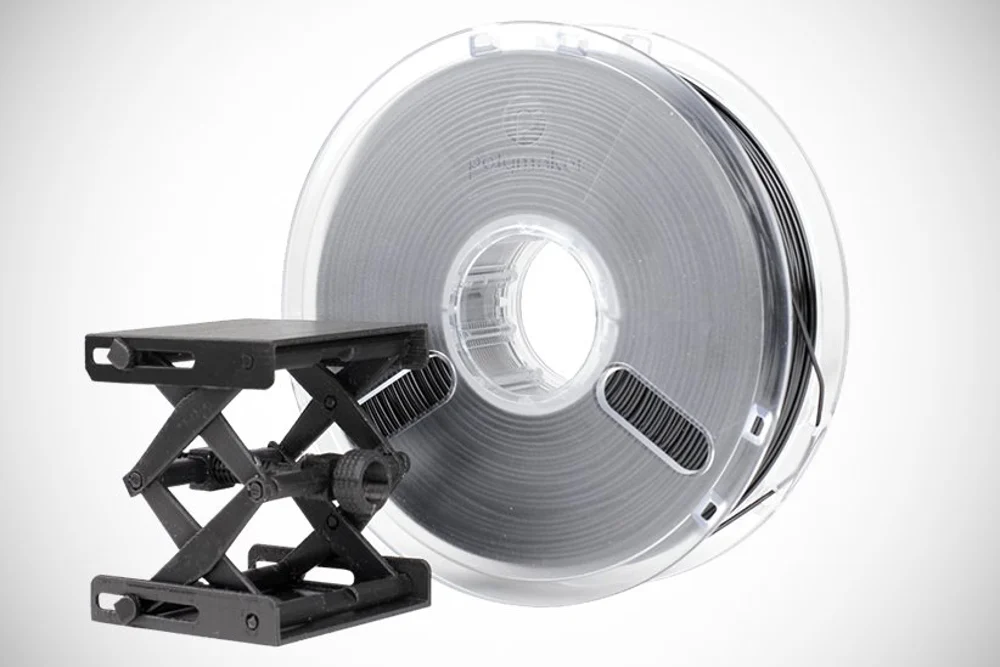

Getting your hands on a 3D printer opens the door to a universe of possibilities. Be it something functional like prosthetics or recreational like tabletop gaming parts – there’s one common need tying it all together: 3D printer filament.

The raw material that keeps you printing, there’s an abundance of 3D printer filament choices available to you. But what are the different types of 3D printer filament? When should you use them?

Below, we cover all of the everyday 3D printer filaments, such as PLA and PETG, plus the tougher engineering-grade materials and the fancy stuff that lets you get creative (frequently referred to as exotics). In addition to the likes of nylon, polycarbonate, carbon fiber reinforced, and polypropylene, there are also special blends with unusual properties like electrical conductivity and luminescence.

With such variety to hand, it’s easier than ever to create functional, visually striking, and high-performing prints. To help you find the right materials, here’s our buyer’s guide for 3D printer filament – 26 filament materials in total split over three sections:

THE BASICS

This first category introduces the six most commonly used types of 3D printer filament in desktop 3D printing, all popular for their ease of use and physical properties.

PLA

WHAT IS PLA?

In the realm of consumer 3D printing, polylactic acid (PLA) is king. Although it’s often compared to ABS – arguably the next in line to the throne – PLA is easily the most popular 3D printer filament type, and for good reason.

3D PRINTER FILAMENT PROPERTIES: PLA

- Strength: High | Flexibility: Low | Durability: Medium

- Difficulty to use: Low

- Print temperature: 180 – 230°C

- Print bed temperature: 20 – 60°C (but not needed)

- Shrinkage/warping: Minimal

- Soluble: No

- Food safety: Refer to manufacturer guidelines

MORE INFORMATION

First and foremost, PLA is easy to print with. It has a lower printing temperature than ABS, and it doesn’t warp as easily, meaning it doesn’t require a heating bed (although it definitely helps). Another benefit of using PLA is that it doesn’t give off an offputting odor during printing (unlike ABS). It’s generally considered an odorless filament, but many have reported smelling sweet candy-like fumes depending on the type of PLA.

Another appealing aspect of PLA is it’s available in a nearly endless abundance of colors and styles. As you’ll see in the exotics sections, many of these specialty filaments use PLA as the base material, such as those with conductive or glow-in-the-dark properties or those infused with wood or metal.

PLA is, to a point, more environmentally friendly than many 3D printer filaments. It will biodegrade under certain commercially attainable conditions. You’re not going to be able to compost it at home, which makes us reluctant to tout the material as being “green” in any meaningful way, but you could spin an argument for it being better than some.

WHEN SHOULD I USE PLA 3D PRINTER FILAMENT?

In this case, the better question might be, When shouldn’t I use PLA? Compared to other types of 3D printer filament, PLA is brittle, so avoid using it when making items that might be bent, twisted, or repeatedly dropped, such as phone cases, high-wear toys, or tool handles.

You should also avoid using it with items that need to withstand higher temperatures, as PLA tends to deform around temperatures of 60°C or higher. For all other applications, PLA makes for a good overall choice in 3D printer filament.

Common prints includemodels, low-wear toys, prototype parts, and containers.

RECAP OF PLA 3D PRINTER FILAMENT

- Pros: Easy to print, wide variety of colors/styles, biodegradable

- Cons: Brittle, lackluster mechanical properties

ABS

WHAT IS ABS?

Acrylonitrile butadiene styrene (ABS) is less popular than PLA for everyday 3D printing. With respect to its material properties though, ABS is actually moderately superior to PLA, despite being slightly more difficult to print – it’s prone to warping without a hot print bed and bed adhesive.

Commonly used in injection molding, ABS is found in many manufactured household and consumer goods, including LEGO bricks and bicycle helmets.

3D PRINTER FILAMENT PROPERTIES: ABS

- Strength: High | Flexibility: Medium | Durability: High

- Difficulty to use: Medium

- Print temperature: 210 – 250°C

- Print bed temperature: 80 – 110°C

- Shrinkage/warping: Considerable

- Soluble: In esters, ketones, and acetone

- Food safety: Not food safe

MORE INFORMATION

Products made of ABS boast high durability and a capacity to withstand high temperatures, but 3D printer enthusiasts should be mindful of the filament’s high printing temperature, tendency to warp during cooling, and intense, potentially hazardous fumes. Be sure to print with a heated bed and a well-ventilated space (or with an enclosure).

WHEN SHOULD I USE ABS 3D PRINTER FILAMENT?

ABS is tough – able to withstand high stress and temperature. It’s also moderately flexible, though there are certainly better options for that further down this list. Together these properties make ABS a good general-purpose 3D printer filament, but where it really shines is with items that are frequently handled, dropped, or heated. Examples include phone cases, high-wear toys, tool handles, automotive trim components, and electrical enclosures.

RECAP OF ABS 3D PRINTER FILAMENT

- Pros: High strength, high durability, resistance to high temperatures

- Cons: Warps easily, hazardous fumes, requires a high-temperature print nozzle

PETG (PET, PETT)

WHAT IS PETG?

Polyethylene terephthalate (PET) is one of the most commonly used plastics in the world. Best known as the polymer used in water bottles, it is also found in clothing fibers and food containers. While “raw” PET is rarely used in 3D printing, its variant PETG is an increasingly popular 3D printer filament.

3D PRINTER FILAMENT PROPERTIES: PETG (PET, PETT)

- Strength: High| Flexibility: Medium | Durability: High

- Difficulty to use: Low

- Print temperature: 220 – 250°C

- Print bed temperature: 50 – 75°C

- Shrinkage/warping: Minimal

- Soluble: No

- Food safety: Refer to manufacturer guidelines

MORE INFORMATION

The ‘G’ in PETG stands for “glycol.” As a material for 3D printing, it is naturally clearer, less brittle, and most importantly, easier to print with than its base form. For this reason, PETG is often considered a good middle ground between ABS and PLA, two other commonly used types of 3D printer filament – it is more flexible and durable than PLA and easier to print than ABS.

Polyethylene coTrimethylene Terephthalate (PETT) is another PET variant. Slightly more rigid than PETG, this 3D printer filament is popular for its transparency.

Three things 3D printer enthusiasts should keep in mind when using PETG:

- PETG is hygroscopic, meaning it absorbs moisture from the air. This has a negative effect on the printability of the material, so make sure to store the 3D printer filament in a cool, dry place and, if necessary, dry it before use.

- PETG is sticky when printed, making this 3D printer filament a poor choice for support structures but good for layer adhesion.

- Though not brittle, PETG scratches more easily than ABS.

WHEN SHOULD I USE PETG (PET, PETT) 3D PRINTER FILAMENT?

PETG is a good all-rounder but stands out from many other types of 3D printer filament due to its flexibility, strength, and resistance to high temperature and impact. This makes it an ideal 3D printer filament to use for functional objects which might experience sustained or sudden stress, such as mechanical parts, printer parts, and protective components.

RECAP OF PETG 3D PRINTER FILAMENT

- Pros: Flexible, durable, easy to print

- Cons: Susceptible to moisture, surface scratches easily

TPE, TPU, TPC (Flexible)

WHAT IS TPE?

As the name implies, thermoplastic elastomers (TPE) are essentially plastics with rubber-like qualities, making them extremely flexible and durable. As such, TPE is commonly used to produce automotive parts, household appliances, and medical supplies.

3D PRINTER FILAMENT PROPERTIES: TPE, TPU, TPC (FLEXIBLE)

- Strength: Medium | Flexibility: Very High| Durability: Very High

- Difficulty to use: Medium (TPE, TPC); Low(TPU)

- Print temperature: 210 – 230°C

- Print bed temperature: 30 – 60°C (but not needed)

- Shrinkage/warping: Minimal

- Soluble: No

- Food safety: Not food safe

MORE INFORMATION

In reality, TPE is a broad class of co-polymers (and polymer mixtures), but it is nonetheless used to label many commercially available types of 3D printer filament. Soft and stretchable, these filaments can withstand the kind of physical punishment that neither ABS nor PLA can tolerate. On the other hand, printing is not always easy, as TPE can be difficult to extrude.

WHAT IS NYLON?

Nylon, a popular family of synthetic polymers used in many industrial applications, is a go-to in powder-fusion methods of 3D printing. As a filament for 3D printing, it excels where strength, flexibility, and durability are key requirements.

3D PRINTER FILAMENT PROPERTIES: NYLON

- Strength: High | Flexibility: High | Durability: High

- Difficulty to use: Medium

- Print temperature: 240 – 260°C

- Print bed temperature: 70 – 100°C

- Shrinkage/warping: Considerable

- Soluble: No

- Food safety: Refer to manufacturer guidelines

MORE INFORMATION

Another unique characteristic of this 3D printer filament is that you can dye it, either before or after the printing process. The negative side to this is that nylon, like PETG, is hygroscopic, meaning it absorbs moisture, so remember to store it in a cool, dry place to keep the filament in prime condition, ensuring better quality prints.

PC (Polycarbonate)

WHAT IS PC?

Polycarbonate (PC), in addition to being one of the strongest 3D printer filaments presented in this list, is extremely durable and resistant to both physical impact and heat, able to withstand temperatures of up to 110°C. It’s also naturally transparent, which explains its use in commercial items such as bulletproof glass, scuba masks, and electronic display screens.

3D PRINTER FILAMENT PROPERTIES: PC (POLYCARBONATE)

- Strength: Very High| Flexibility: Medium | Durability: Very High

- Difficulty to use: Medium

- Print temperature: 270 – 310°C

- Print bed temperature: 90 – 110°C

- Shrinkage/warping: Considerable

- Soluble: No

- Food safety: Not food safe

MORE INFORMATION

Despite being featured in similar use cases, PC shouldn’t be confused with acrylic or plexiglass, which tend to shatter or crack under stress. Unlike these two materials, PC is moderately flexible (though not as much as nylon, for example), allowing it to bend until it eventually deforms.

PC 3D printer filament is hygroscopic, absorbing water from the air, so remember to store it in a cool, dry place to ensure better quality prints.

WHEN SHOULD I USE PC 3D PRINTER FILAMENT?

Due to its physical properties, PC is an ideal 3D printer filament for parts that need to retain their strength, toughness, and shape in high-temperature environments, such as electrical, mechanical, or automotive components. You can also leverage its optical clarity for lighting projects, screens, and other applications that call for transparency.

RECAP OF PC 3D PRINTER FILAMENT

- Pros: Extremely strong, resistant to heat and physical impact

- Cons: Susceptible to moisture, requires very high print temperature

EXOTIC AND FUNKY TYPES OF 3D PRINTER FILAMENT

Having paid the proper respects to the Big Six, the gods of 3D printing should now be appeased. Time to move on to something a little more fun!

Where before, we mostly focused on physical characteristics like strength, flexibility, and durability; the next eight 3D filament types are popular for their finish, composition, and other special characteristics.

Thanks to their exotic natures, these filaments are especially popular in recreational 3D printer use. In other words, this is the fun category!

Wood-Filled

WHAT IS WOOD-FILLED FILAMENT?

Interested in printing objects that look and feel like wood? Well, you can! Of course, it’s not really wood – that wouldn’t make for a very good 3D printer filament. Wood 3D printer filament is typically a PLA infused with wood fiber.

MORE INFORMATION

There are many wood-PLA 3D printer filaments available today. These include the more standard wood varieties, such as Pine, Birch, Cedar, Ebony, and Willow, but the range also extends to less common types, like Bamboo, Cherry, Coconut, Cork, and Olive.

As with other types of 3D printer filament, there is a trade-off with using wood. In this case, the aesthetic and tactile appeal comes at the cost of reduced flexibility and strength.

Be careful with the temperature at which you print wood, as too much heat can result in an almost burnt or caramelized appearance. On the other hand, the base appearance of your wooden creations can be greatly improved with a little post-print processing! Wood-filled filament can also accelerate the degradation of your 3D printer’s nozzle, so keep that in mind before using this material.

WHEN SHOULD I USE WOOD-FILLED FILAMENT?

Wood is popular with items that are appreciated less for their functional capabilities and more for their natural appearance. Consider using wood-filled 3D printer filament when printing objects displayed on a desk, table, or shelf. Examples include bowls, figurines, and awards. One really creative application of wood as a 3D printer filament is creating scale models, such as those used in architecture.

RECAP OF WOOD-FILLED FILAMENT

- Pros: Aesthetically striking, ideal for visual models

- Cons: Lackluster mechanical properties, abrasive to the print nozzle

Metal-Filled

WHAT IS METAL FILLED FILAMENT?

Maybe you’re looking for a different type of aesthetic in your prints – something a little bulkier and shinier. Well, for that, you can use metal. Like wood-filled 3D printer filament, metal-filled filament isn’t fully made from metal. It’s actually a mix of metal powder and either PLA or ABS. But that doesn’t stop the results from having the look and feel of metal.

Even the weight is metal-like, as blends tend to be several times denser than pure PLA or ABS.

MORE INFORMATION

Bronze, brass, copper, aluminum, and stainless steel are just a few of the varieties of metal 3D printer filaments commercially available. And if there’s a specific look you’re interested in, don’t be afraid to polish, weather, or tarnish your metal items after printing – a little post-processing can go a long way.

You may need to replace your nozzle a little sooner due to printing with metal, as the grains are somewhat abrasive, resulting in increased nozzle wear.

The most common 3D printer filament blends tend to be around 50% metal powder and 50% PLA or ABS, but blends also exist up to 85% metal. For more information on these filaments and how to use them, please look at our Complete Guide to Metal 3D Printing.

WHEN SHOULD I USE METAL FILAMENT?

Metal can be used to print for aesthetics and functionality. For example, figurines, models, toys, and tokens can all look great when 3D printed in metal. And as long as they don’t have to deal with too much stress, feel free to use metal 3D printer filament to create parts with purpose, like tools, grates, or finishing components.

RECAP OF METAL FILAMENT

- Pros: Provides metallic look, ideal for both aesthetic and functional models

- Cons: Difficult to print, highly abrasive to print nozzle

Biodegradable

WHAT IS BIODEGRADABLE FILAMENT?

Biodegradable 3D printer filaments make up a unique category, as their most valuable characteristic does not lie in their physical natures. As most hobbyists can attest to, not every print turns out the way you want it to, and the results in having to throw away a ton of plastic. Biodegradable filaments seek to negate the environmental impact that plastic waste has on our planet.

MORE INFORMATION

As was mentioned earlier in this article, PLA is, to a point, biodegradable filament. But some brands strive further to sustainable production, development, and packaging. This is the case of the French company Kimya, with its OWA series that recycles 2D printer toners. It even offers the possibility of recovering the waste from your machine to recycle it again. There is also the company Biome3D with its line of BioFila filaments, with the goal of prints that can be processed in your local plastic recycling stream. Although these materials do not offer a great variation in terms of strength or flexibility, they’re some of the nobler options to start in 3D printing.

WHEN SHOULD I USE BIODEGRADABLE 3D PRINTER FILAMENT?

Regardless of their primary reason for existing being environmentally friendly, biodegradable 3D printer filament types can still produce items of sound physical quality. Use them any time you don’t have specific requirements for strength, flexibility, or endurance. And if you really want to take advantage of the guilt-free printing biodegradable filaments offer, try to use them in limited-use projects you know will be discarded, such as prototyping.

RECAP OF BIODEGRADABLE 3D PRINTER FILAMENT

- Pros: Environmentally-friendly

- Cons: Lackluster mechanical properties, limited selection, tend to be expensive

Conductive

WHAT IS CONDUCTIVE FILAMENT?

With so many strong, flexible, and durable types of 3D printer filament available, structural and mechanical projects are everywhere, it seems. Enter conductive 3D printer filaments — filament that does as its name implies: conduct electricity.

MORE INFORMATION

With the addition of conductive carbon particulates to PLA or ABS, it’s easy to actualize hobbyist projects by printing low-voltage electronic circuits. Just couple a conductive 3D printer filament with an ordinary PLA or ABS in a dual-extrusion machine.

WHEN SHOULD I USE CONDUCTIVE 3D PRINTER FILAMENT?

Even though this 3D printer filament type only supports low-voltage circuitry, the sky’s the limit with customized electronics projects. If you’re experimenting, try coupling a circuit board with LEDs, sensors, or even a Raspberry Pi! If you’re looking for something a little more specific, popular ideas include gaming controllers, digital keyboards, and trackpads.

RECAP OF CONDUCTIVE 3D PRINTER FILAMENT

- Pros: Ideal for electronics projects

- Cons: Limited selection

Glow-in-the-Dark

WHAT IS GLOW-IN-THE-DARK FILAMENT?

It’s glow-in-the-dark 3D printer filament – pretty self-explanatory. Leave your print in the light for a while, then flick the switch and behold that eerie green glow.

It doesn’t have to be green, of course. Other glow-in-the-dark filament colors include blue, red, pink, yellow, or orange. But green tends to be the most popular and replicates that classic spooky glow.

MORE INFORMATION

So, how does it work? It all comes down to the phosphorescent materials mixed in with the PLA or ABS base. Thanks to these added materials, a glow-in-the-dark 3D printer filament is able to absorb and later emit photons, basically elemental particles of light. This is why your prints will only glow after being in the light – they have to store the energy before they can release it.

For best results, consider printing with thick walls and little infill. The thicker your walls, the stronger the glow!

WHEN SHOULD I USE GLOW-IN-THE-DARK 3D PRINTER FILAMENT?

Thinking about that eerie green glow, it almost doesn’t even seem necessary to suggest using a glow-in-the-dark 3D printer filament for Halloween projects, like jack-o’-lanterns or window decorations. Other examples of where these filaments really shine – er, glow – include wearables (think jewelry), toys, and figurines.

RECAP OF GLOW-IN-THE-DARK 3D PRINTER FILAMENT

- Pros: Visually striking (It glows in the dark!)

- Cons: Limited mechanical properties

Magnetic

WHAT IS MAGNETIC FILAMENT?

Are metal and conductive prints not exciting enough for you? Okay then, how about magnetic prints? This exotic 3D printer filament, a base of PLA or ABS with powdered iron, features a grainy, gunmetal finish, and of course, it sticks to magnets!

MORE INFORMATION

One thing to note: Despite the name, this 3D printer filament type is actually ferromagnetic, meaning that while it is attracted to magnetic fields, it has no fields of its own. In other words, the objects you print may stick to magnets, but they won’t actually be magnets.

WHEN SHOULD I USE MAGNETIC 3D PRINTER FILAMENT?

Use this type of 3D printer filament whenever you want your prints to stick to something magnetic. Ornaments (especially for the fridge) are the most obvious example, but why not incorporate some magnetism into toys or tools?

RECAP OF MAGNETIC 3D PRINTER FILAMENT

- Pros: Sticks to magnets, visually appealing

- Cons: Expensive

Color-Changing

WHAT IS COLOR-CHANGING FILAMENT?

Remember those T-shirts from the 80s, the ones that would change color based on body temperature? Or how about mood rings? Well, this is the same idea; color-changing 3D printer filaments also change color based on temperature changes.

MORE INFORMATION

Filaments from this category tend to change between a gradient of two colors, for example, from purple to pink, blue to green, or yellow to green.

As with other exotic types of 3D printer filament, color-changing filament exists in blends of both PLA and ABS.

WHEN SHOULD I USE COLOR-CHANGING 3D PRINTER FILAMENT?

With no special physical, tactile, or functional characteristics, this type of 3D printer filament is purely designed for aesthetically driven applications. Use it whenever you would normally use PLA or ABS, but desire that extra visual flare. Good candidate projects include phone cases, wearables, toys, and containers.

RECAP OF COLOR-CHANGING 3D PRINTER FILAMENT

- Pros: Aesthetically pleasing, can be used to detect heat and other environmental elements

- Cons: Limited mechanical properties

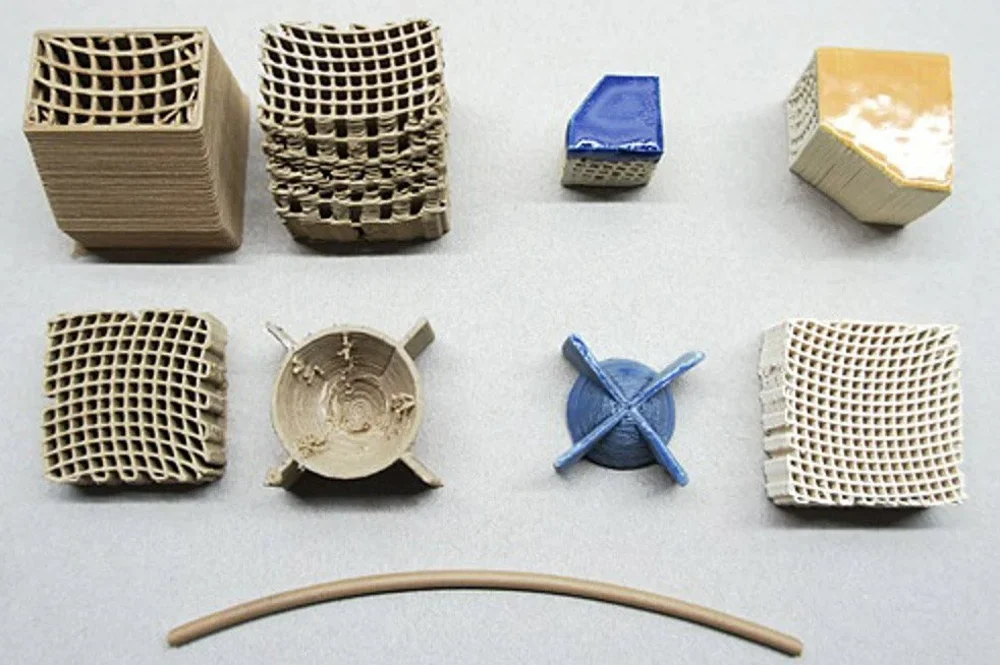

Clay/Ceramic

WHAT IS CLAY/CERAMIC FILAMENT?

As evidenced by this article, plastic tends to dominate 3D printing as the primary print material. We’ve explored some other non-plastic options already, and here’s another: clay. Boasting earthenware properties, clay 3D printing filament typically contains a mixture of clay and polymer.

MORE INFORMATION

There aren’t many companies offering stone/earthen material-based filaments. Clay (often marketed as ceramic) is the one with perhaps the strongest use case: faux-pottery.

A common characteristic shared between these filaments is brittleness – care is required to properly handle and print them.

Lay Filament’s LAYCeramic is one example of a ceramic filament that achieves near-authentic results. Fireable in a kiln after printing, the polymer binding the ceramic particles within de-binds to leave behind a slightly shrunken, but hardened, final print that can be spruced up with a ceramic glaze and other post-processing effects.

WHEN SHOULD I USE CLAY/CERAMIC 3D PRINTER FILAMENT?

When you’re looking for handmade earthenware, look paired to the impossibly precise repeatability 3D printing gives.

RECAP OF CLAY/CERAMIC 3D PRINTER FILAMENT

- Pros: Provides clay-like properties, can be fired in a kiln

- Cons: Parts will shrink after post-processing, the filament is expensive

PROFESSIONAL TYPES OF 3D PRINTER FILAMENT

We’ve given the following types of 3D printer filament the label “professional” for two reasons:

First, compared to those already discussed, the remaining types of 3D printer filament are less commonly seen in desktop 3D printing, being more popular among extreme hobbyists and frequently appearing in industrial and commercial scenarios.

Second, many of the following filaments provide a function apart from simply being a print material, such as structural support or extruder cleaning.

That’s not to say that they are off-limits for casual use. Most print in much the same way as the filaments mentioned above, albeit with more attention paid to print settings or special requirements that can be modded onto a standard desktop 3D printer (such as a hotter hot end).

Carbon Fiber

WHAT IS CARBON FIBER FILAMENT?

When 3D printer filament, such as PLA, ABS, but most typically nylon, is reinforced with carbon fiber, the result is an extremely stiff and rigid material with relatively little weight. Such compounds shine in structural applications that must withstand a wide variety of end-use applications.

MORE INFORMATION

The trade-off is the increased wear and tear on your printer’s nozzle, especially if it’s made of a soft metal like brass. Even as little as 500 grams of this exotic 3D printer filament will noticeably increase the diameter of a brass nozzle, so unless you enjoy frequently replacing your nozzle, consider using one made of (or coated with) a harder material.

WHEN SHOULD I USE CARBON FIBER 3D PRINTER FILAMENT?

Thanks to its structural strength and low density, carbon fiber is a fantastic candidate for mechanical components. Looking to replace a part in your model car or plane? Give this 3D printer filament a try.

RECAP OF CARBON FIBER 3D PRINTER FILAMENT

- Pros: Strong and lightweight material, ideal for functional applications

- Cons: Causes wear and tear on 3D printer nozzle

Glass Fiber

WHAT IS GLASS FIBER FILAMENT?

Glass fiber-filled filament typically consists of nylon reinforced with chopped glass fibers, just like carbon fiber-filled filament detailed above. Glass fiber reinforced materials have characteristically high impact and temperature resistance, plus tensile strength that allows them to withstand large amounts of energy while maintaining shape and structural integrity.

MORE INFORMATION

Since the base thermoplastic of glass fiber-filled filament is nylon, it (unsurprisingly) needs similar temperatures to said material. It may vary from brand to brand but typically requires the hot end to hit 250 °C and above. An abrasion-resistant stainless steel nozzle is strongly recommended. Glass-filled filament should be stored in a dry place and heated before use to yield the best results (again, the characteristics of handling and printing it are dictated by it, usually being nylon.)

WHEN SHOULD I USE GLASS FIBER 3D PRINTER FILAMENT?

This durable fiber is suited for many mechanical components that require high rigidity and structural strength. Heat and scratch resistance are strong considerations for the use of glass fiber filament, too.

RECAP OF GLASS FIBER 3D PRINTER FILAMENT

- Pros: Rigid and durable material, ideal for mechanical applications

- Cons: Causes wear and tear on 3D printer nozzle, layer adhesion issues

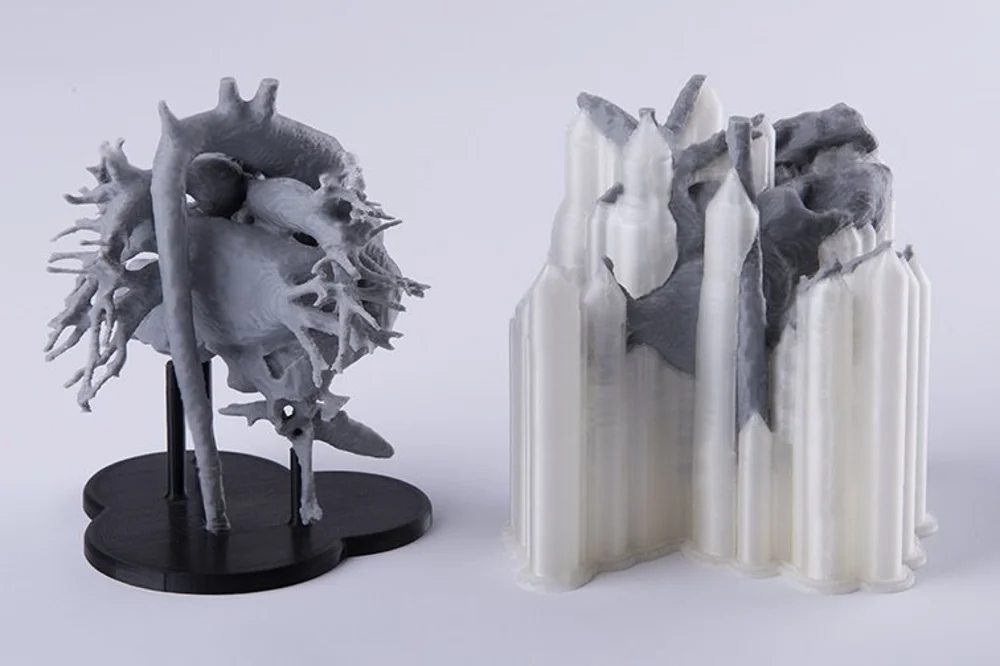

Metal

WHAT IS METAL FILAMENT?

Professional metal filament comprises a high percentage of metal powder plus binders with the result of a 3D printable filament that can be sintered into fully dense metal parts. Once printed, debinding and sintering processes are applied to remove the binder and produce the final, full metal part. An industrial-grade material brought to the desktop, there are currently a few metal 3D printer filaments available including 316L stainless steel, tool steel, Inconel, copper, and aluminum.

These filaments can be printed on most FDM 3D printers, providing they are equipped with a large-bore abrasion-resistant nozzle. A heated chamber and high-temperature heated bed are beneficial.

MORE INFO

After printing, the object is in its so-called “green state.” In order to be sintered without any defects, the polymer matrix is then removed in the debinding process, creating the “brown” part. In this state, the object has open-pore channels throughout. Parts not suited to this process can suffer from distortion or even collapse under their own weight.

In the third and final step, the brown body is sintered and turned into a metal object. A non-isotropic material shrinkage occurs, which must already be taken into account when designing or preparing the object for print. Depending on the material, percentages vary from 5–20% (specific detail will be found on the filament’s spec sheet.)

WHEN SHOULD I USE METAL FILAMENT?

Because of their high strength and corrosion resistance, metal-based filaments are ideal for manufacturing parts such as fixtures, fasteners, tools, and functional and end-use parts.

RECAP OF METAL 3D PRINTER FILAMENT

- Pros: A unique type of composite filament that yields strong, chemical resistant solid metal parts when used properly

- Cons: A demanding process that requires far more attention to detail and design than ordinary desktop printing

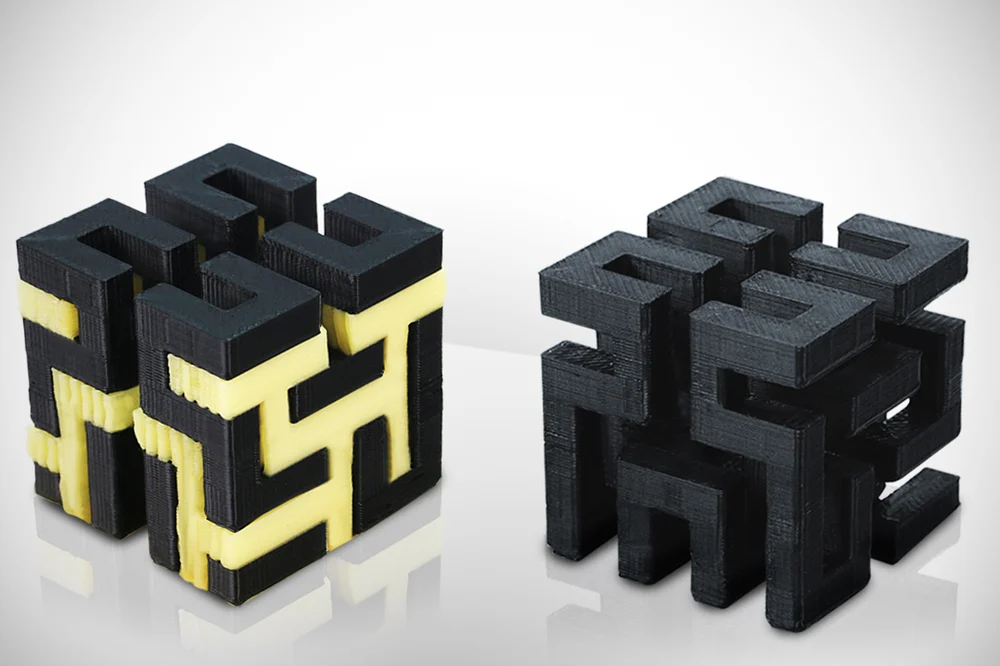

HIPS

WHAT IS HIPS FILAMENT?

In the commercial world high impact polystyrene (HIPS), a copolymer that combines the hardness of polystyrene and the elasticity of rubber, is commonly found in protective packaging and containers, like CD cases.

In the world of 3D printing, HIPS typically plays a different role. 3D printers can’t print onto thin air – that’s where support structures come in. Overhangs require some underlying structure, and this is where HIPS really shines. When paired with ABS in a dual extrusion printer, HIPS acts as an excellent support material.

MORE INFORMATION

For dual extrusion printing with HIPS, simply crank the supports to the max and fill any gaps in your design with HIPS 3D printer filament. Immersing the finished print in limonene will dissolve the HIPS, leaving your final product behind.

Unfortunately, using HIPS as a support material limits you to printing your actual part from ABS. The limonene will damage other 3D printer filament materials. Handily, HIPS and ABS print well together in any case, being of similar strength, stiffness, and requiring a comparable print temperature.

In fact, despite its primary use as a support material, HIPS is a decent 3D printer filament in its own right. It is stronger than PLA and ABS, warps less than ABS, and can easily be glued, sanded, and painted.

WHEN SHOULD I USE HIPS 3D PRINTER FILAMENT?

Sharing many characteristics with ABS, HIPS 3D printing filament is a good all-rounder for parts that need to stand up to wear and tear or for projects that require a finishing-friendly material to achieve the end look.

RECAP OF HIPS 3D PRINTER FILAMENT

- Pros: Can be used as a support material and strong 3D printer filament

- Cons: Requires post-processing to remove supports, only compatible with ABS

PVA

WHAT IS PVA?

Polyvinyl alcohol (PVA) is soluble in water, and that’s exactly what commercial applications take advantage of. Popular uses include packaging for dishwasher detergent “pods” or bags full of fishing bait. (Throw the bag in water and watch it dissolve, releasing the bait.)

MORE INFORMATION

The same principle applies in 3D printing, making PVA a great support material when paired with another 3D printer filament in a dual extrusion 3D printer. The advantage of using PVA over HIPS is that it can support more materials than just ABS.

The trade-off is a 3D printer filament that is slightly more difficult to handle. One must also be careful when storing it, as the moisture in the atmosphere can damage the filament before printing. Dry boxes and silica pouches are a must if you plan to keep a spool of PVA usable in the long run.

WHEN SHOULD I USE PVA 3D PRINTER FILAMENT?

PVA filament is a great choice as support material on complex prints with overhangs.

RECAP OF PVA 3D PRINTER FILAMENT

- Pros: Terrific support material

- Cons: Difficult to handle, susceptible to moisture

Cleaning

WHAT IS CLEANING FILAMENT?

Unlike the other filaments in this list, cleaning 3D printer filament is not used to print objects but to clean 3D printer extruders. Its purpose is to remove any material in the hot end that might have been left over from previous prints. Though a good general practice, using cleaning 3D printer filament is especially useful when transitioning between materials that have different print temperatures or colors.

MORE INFORMATION

The general procedure involves manually feeding cleaning 3D printer filament into a heated print head to force out the old material, then cooling the hot end slightly and yanking the filament back out again. For more detailed instructions, take a look at the manufacturer’s information for the specific filament you’re using.

A few extra things to note:

- “Print” temperature depends on whatever types of 3D printer filament you used before, as well as on the one you want to use next. (Cleaning 3D printer filament is stable anywhere between 150 and 280°C.)

- It’s not typically necessary to use more than 10 cm of filament at a time.

- Other cleaning methods exist, including the popular “cold pull” technique, which is similar to the above procedure and does not require cleaning 3D printer filament.

WHEN SHOULD I USE CLEANING 3D PRINTER FILAMENT?

You should consider cleaning 3D printer filament between prints using two materials with wildly different temperature requirements or colors. Generally speaking, it’s important to give your hot end a bit of TLC every once in a while.

RECAP OF CLEANING 3D PRINTER FILAMENT

- Pros: Cleans nozzle when switching between different filaments

- Cons: Adds time to the printing process, limited usefulness

Wax (MOLDLAY)

WHAT IS WAX (MOLDLAY) FILAMENT?

Want to print something in real brass, tin, or some other metal? Well, you can! Kind of… In reality, you’ll be printing a mold using a wax 3D printer filament. But after a few extra steps, your design really can come to shiny, metal life.

MORE INFORMATION

The process is called “lost-wax” or “investment” casting, and it more-or-less works like this:

- Create a positive wax mold – a wax replica of what you want the final metal product to look like.

- Dip the mold in plaster and let it dry.

- Put the wax-plaster object in an oven. At a high enough temperature, the wax will melt away, leaving a negative space within the plaster, in which the metal product can be cast.

Wax 3D printer filament makes the first step easy, as one would normally have to carve the mold out of a block of wax.

Dominating the wax 3D printer filament arena is MOLDLAY by Kai Parthy CC Products. When using this or similar wax-like materials, keep in mind that they are much softer than most types of 3D printer filament. Among other precautions, it may be necessary to modify your extruder and layer your print bed with an adhesive.

WHEN SHOULD I USE WAX (MOLDLAY) 3D PRINTER FILAMENT?

If you’re casting pieces from metals, wax-like filaments like MOLDLAY could give you greater flexibility with the ability to directly 3D print intricate and complex designs that fit into a lost-wax casting workflow.

RECAP OF WAX 3D PRINTER FILAMENT

- Pros: Create molds with your 3D printer

- Cons: Requires modifications to extruder and print bed, limited applications

ASA

WHAT IS ASA FILAMENT?

Sure, ABS is great, but it has its flaws. As filament it typically contains additives that help make it printable in the first place. Compared to its use in injection molding, it’s not quite the same, which is why there’s no shortage of ABS-like alternatives for 3D printing. One such alternative is acrylonitrile styrene acrylate (ASA), which was originally developed to be a hardy weather-resistant material. It is commonly used in the automotive industry.

MORE INFORMATION

In addition to being a 3D printer filament that is strong, rigid, and relatively easy to print with, ASA is also extremely resistant to chemical exposure, heat. Extreme condition excepted, it generally won’t change shape or color. For example, prints made of ABS tend to denature and yellow if left outdoors. Not the case with ASA.

Another minor benefit to using ASA over ABS is that it warps less during printing. But be careful with how you adjust your cooling fan; ASA can easily delaminate (crack at the layers) if your print cooling is too strong.

WHEN SHOULD I USE ASA 3D PRINTER FILAMENT?

For anything from birdhouses to custom garden gnomes and replacement outlet covers, look no further than this 3D printer filament.

RECAP OF ASA 3D PRINTER FILAMENT

- Pros: Great for functional applications, especially automotive parts

- Cons: Susceptible to cracking during the printing process

Polypropylene (PP)

WHAT IS PP?

Polypropylene (PP) is tough, flexible, light, chemically resistant, and food-safe, which might explain its broad range of applications, including engineering plastics, food packaging, textiles, and banknotes.

MORE INFORMATION

Unfortunately, PP is notoriously difficult to print with, often presenting heavy warpage and lackluster layer adhesion. If not for these issues, PP may have contended with PLA and ABS for the most popular 3D printer filament types, given its strong mechanical and chemical properties.

Interestingly, since many household objects are made of PP, it’s actually possible to recycle old junk and turn it into new filament.

WHEN SHOULD I USE PP 3D PRINTER FILAMENT?

If you can wrest PP’s warping under control, then most prints calling for a hardy and light material would suit PP. It’s important to note, however, that while the material sees great use in the packaging of consumables and medicine for its food-safe properties, the process of FDM 3D printing negates this with hundreds (if not thousands) of layer lines for bacteria to hang out in – best not to try.

RECAP OF PP 3D PRINTER FILAMENT

- Pros: Strong mechanical properties, chemical resistant

- Cons: Difficult to print with, prone to warping, poor layer adhesion

PC / ABS

WHAT IS PC-ABS FILAMENT?

Polycarbonate ABS alloy (PC-ABS) is a tough thermoplastic, combining the strength and heat resistance of polycarbonate with the flexibility of ABS. Commonly found in automotive, electronics, and telecommunications applications, it is one of the most widely used industrial thermoplastics globally.

MORE INFORMATION

The same benefits apply when used as a 3D printer filament, but the trade-off is a slightly more complicated printing process. First, because PC-ABS is hygroscopic, it’s recommended to bake it before printing (or, at the very least, store it in a proper environment). Second, it requires a high printing temperature (of at least 260°C). Third, it tends to warp, so a high print bed temperature is also necessary (at least 100°C, and as high as 140°C).

WHEN SHOULD I USE PC-ABS 3D PRINTER FILAMENT?

Functional prototyping, tooling, and small-batch end-use parts that need to withstand small shocks and impacts are a good fit for PC/ABS.

RECAP OF PC-ABS 3D PRINTER FILAMENT

- Pros: Offers the best qualities of PC and ABS materials

- Cons: Requires high temperature for nozzle and print bed, susceptible to moisture

Acetal (POM)

WHAT IS ACETAL (POM) FILAMENT?

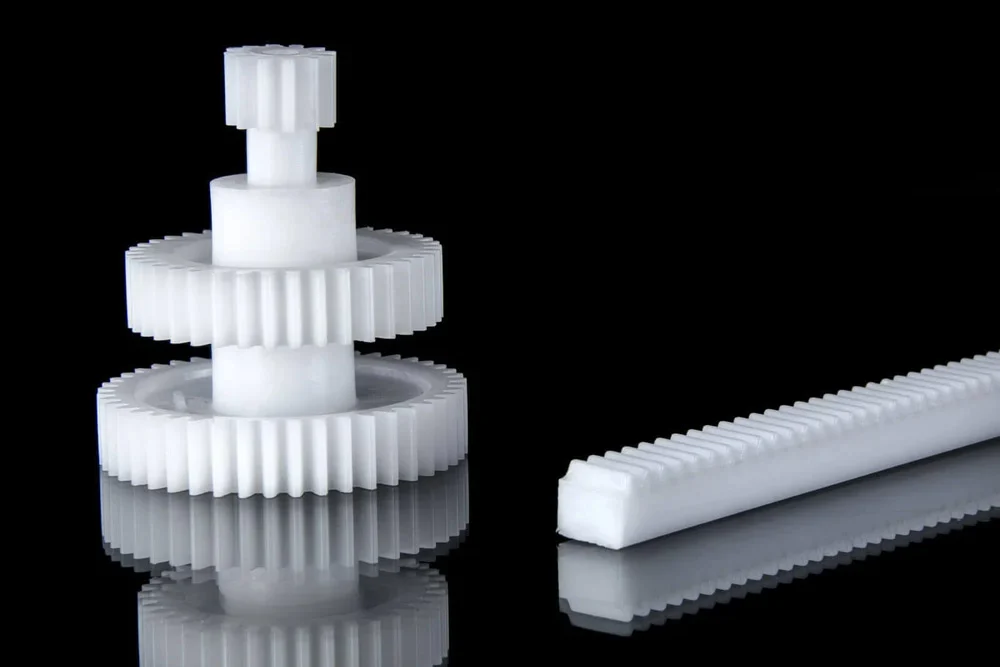

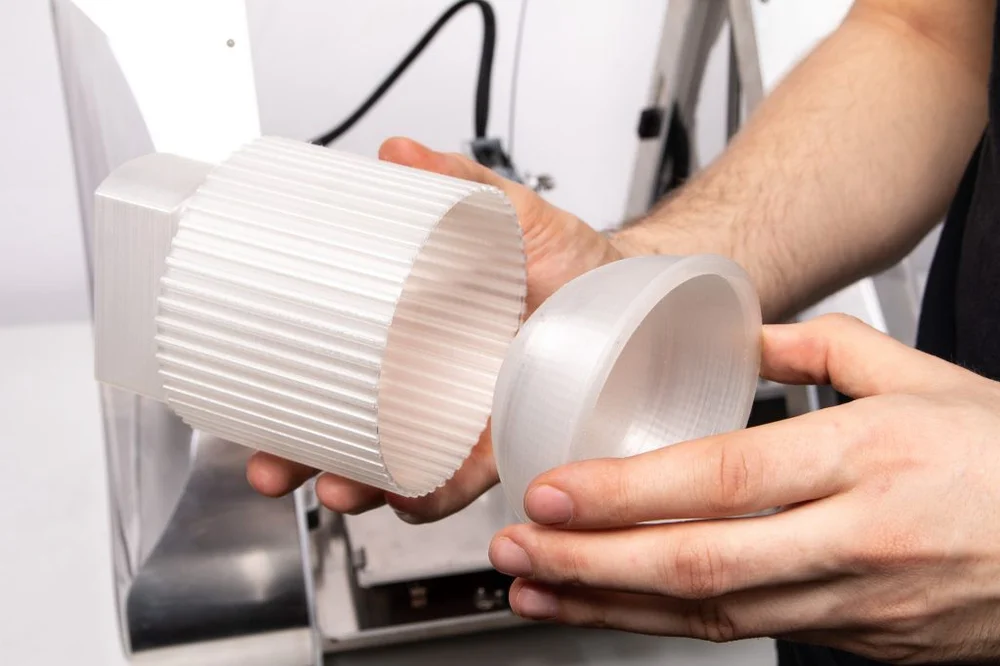

Polyoxymethylene (POM), also referred to as acetal and Delrin, is well known for its use as an engineering plastic, for example, in parts that move or require high precision.

MORE INFORMATION

Acetal as a material sees common use as gears, bearings, camera focusing mechanisms, and zippers.

POM performs exceptionally well in these types of applications due to its strength, rigidity, resistance to wear, and most importantly, its low coefficient of friction. It’s thanks to this last property that POM makes such a great 3D printer filament.

For most of the types of 3D printer filament in this list, there is a significant gap between what is made in the industry and what you can make at home with your 3D printer. For POM, this gap is somewhat smaller; the slippery nature of this material means prints can be nearly as functional as mass-produced parts.

Make sure to use a heated print bed when printing with POM 3D printer filament, as the first layer doesn’t always want to stick.

WHEN SHOULD I USE ACETAL (POM) 3D PRINTER FILAMENT?

Any moving parts need to be low friction and tough. We imagine gearing mechanisms in projects using motors (such as RC cars) could be an applicable field for POM.

RECAP OF ACETAL (POM) 3D PRINTER FILAMENT

- Pros: Good resistance to chemicals and heat, ideal for functional applications

- Cons: Difficulty with first layer adhesion, requires high print bed temperature

PMMA (Acrylic)

WHAT IS PMMA FILAMENT?

Ever heard of polymethyl methacrylate (PMMA)? Maybe not. What about acrylic or Plexiglas? That’s right; we’re talking about the same material that’s most often used as a lightweight, shatter-resistant alternative to glass.

MORE INFORMATION

3D printing with PMMA 3D printer filament can be a little difficult. To prevent warping and maximize clarity, extrusion must be consistent, requiring a high nozzle temperature. It might also help to enclose the print chamber in order to regulate cooling better.

WHEN SHOULD I USE PMMA 3D PRINTER FILAMENT?

Rigid, impact-resistant, and transparent, use this 3D printer filament for anything that should diffuse light, whether that’s a replacement windowpane or a colorful toy. Just don’t use it to make anything that should bend, as PMMA is not very flexible.

RECAP OF PMMA 3D PRINTER FILAMENT

- Pros: Rigid, transparent, and resistant to impact

- Cons: Susceptible to warping, not flexible, requires high print temperature

Source: https://all3dp.com/1/3d-printer-filament-types-3d-printing-3d-filament/