Benefits of injection molding

Injection molding is an established manufacturing technology with a long history, but it’s constantly being refined and improved with new technological advancements.

Below is a quick rundown of the key advantages and disadvantages of injection molding to help you understand whether it’s the right solution for your application.

High-volume manufacturing of plastics

Injection molding is the most cost-competitive technology for manufacturing high volumes of identical plastic parts. Once the mold is created and the machine is set up, additional parts can be manufactured very fast and at a very low cost.

The recommended minimum production volume for injection molding is 500 units. At this point economies of scale start to kick-in and the relatively high initial costs of tooling have a less prominent effect on the unit price.

Wide range of materials

Almost every thermoplastic material (and some thermosets and silicones) can be injection molded. This gives a very wide range of available materials with diverse physical properties to design with.

Parts produced with injection molding have very good physical properties. Their properties can be tailored by using additives (for example, glass fibers) or by mixing together different pellets (for instance, PC/ABS blends) to achieve the desired level of strength, stiffness, or impact resistance.

Very high productivity

The typical injection molding cycle lasts 15 to 60 seconds, depending on the size of the part and the complexity of the mold. In comparison, CNC machining or 3D printing might require minutes to hours in order to produce the same geometry. Also, a single mold can accommodate multiple parts, further increasing the production capabilities of this manufacturing process.

This means that hundreds (or even thousands) of identical parts can be produced every single hour.

Great repeatability and tolerances

The injection molding process is highly repeatable and the produced parts are essentially identical. Of course, some wear occurs to the mold over time, but a typical pilot-run aluminum mold will last 5,000 to 10,000 cycles, while full-scale production molds from tool steel can stand 100,000+ cycles.

Typically, injection molding will produce parts with tolerances of ± 0.500 mm (0.020’’). Tighter tolerances down to ± 0.125 mm (0.005’’) are also feasible in certain circumstances. This level of accuracy is enough for most applications and comparable to both CNC machining and 3D printing.

Excellent visual appearance

A key strength of injection molding is it can produce finished products that need little to no extra finishing. The surfaces of the mold can be polished to a very high degree to create mirror-like parts. Or they can be bead blasted to create textured surfaces. The SPI standards dictate the level of finishing that can be achieved.

Limitations of injection molding

High start-up costs for tooling

The main economic restriction of injection molding the high cost of tooling. Since a custom mold has to be made for each geometry, the start-up costs are very high. These are mainly related to the design and manufacturing of the mold which typically costs between $5,000 and $100,000. For this reason, injection molding is only economically viable for productions larger than 500 units.

Design changes are costly

After a mold is manufactured, it’s very expensive to modify. Design changes usually require the creation of a new mold from scratch. For this reason, correctly designing a part for injection molding is very important.

Below we list the most important design considerations to keep in mind while designing for injection molding. We’ll also see how you can mitigate the risk by creating physical prototypes of your parts.

Longer lead times than other technologies

The typical turnaround for injection molding varies between 6-10 weeks. 4-6 weeks to manufacture the mold, plus 2-4 more weeks for production and shipping. If design changes are required (something quite common) the turnaround time increases accordingly.

In comparison, parts made in a desktop 3D printer can be ready for delivery overnight, while industrial 3D printing systems have a typical lead time of 3-5 days. CNC machined parts are typically delivered within 10 days or as fast as 5 days.

Examples of products made with injection molding

If you look around you right now, you’ll see at least a few products that were manufactured with injection molding. You’re probably looking at one right now actually: the casing of the device you are using to read this guide.

To recognize them, look out for these 3 things: a parting line, witness marks on the hidden side, and a relatively uniform wall thickness throughout the part.

We’ve collected some examples of products commonly manufacturing with injection molding to help get a better understanding of what can be achieved with this manufacturing process.

Lego bricks

Lego bricks are one of the most recognizable examples of injection molded parts. They’re manufactured using molds, like the one in the picture, which produced 120 million lego bricks (that’s 15 million cycles) before it was taken out of commission.

The material used for Lego bricks is ABS because of its high impact resistance and excellent moldability. Every single brick has been designed to perfection, achieving tolerances down to 10 micrometers (or a tenth of a human hair).

This is partly achieved by using the best design practices, which we’ll examine in the next section (uniform wall thickness, draft angles, ribs, embossed text etc.).

Bottle caps

Many plastic packaging products are injection molded. In fact, the packaging is the largest market for injection molding.

For example, bottle caps are injection molded from Polypropylene. Polypropylene (PP) has excellent chemical resistance and is suitable to come in contact with food products.

On bottle caps, you can also see all the common unavoidable injection molding imperfections (parting line, ejector marks etc.) and common design features (ribs, stripping undercuts etc.).

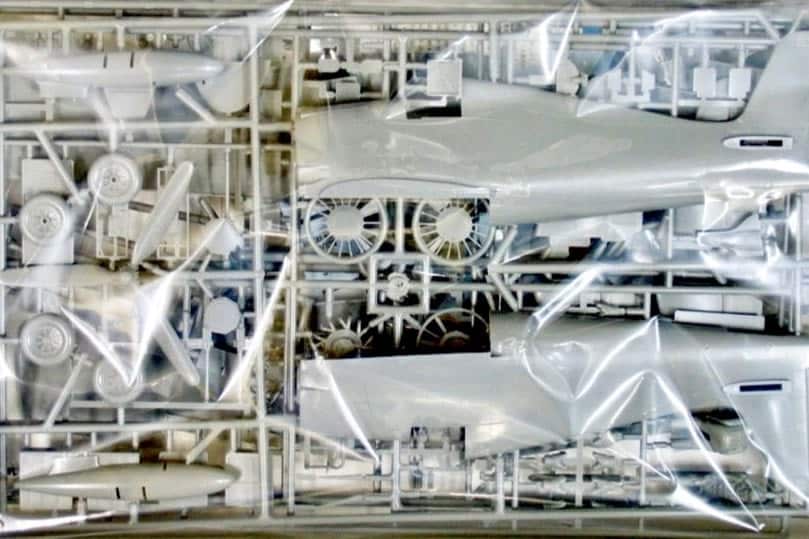

Model airplanes

Model airplanes are another common example of injection molded parts. The material used here is mostly Polystyrene (PS), for its low cost and ease of molding.

What’s interesting with model airplane kits is that they come with the runner system still attached. So, you can see the path the melted plastic followed to fill the empty mold.

Car parts

Almost every plastic component in the interior of a car was injection molded. The 3 most common injection molding materials used in the automotive industry are Polypropylene (PP) for non-critical parts, PVC for its good weather resistance and ABS for its high impact strength.

More than half of the plastic parts of a car are made from one of these materials, including the bumpers, the interior body parts, and the dashboards.

Consumer electronics

The enclosures of almost every mass-produced consumer electronic device were injection molded. ABS and polystyrene (PS) are preferred here for their excellent impact resistance and good electrical insulation.

Medical devices

Many sterilizable and biocompatible materials are available for injection molding.

Medical grade silicone is one of the more popular materials in the medical industry. Silicone is a thermoset though, so special machinery and process control are required, increasing the cost.

For applications with less strict requirements other materials, like ABS, polypropylene (PP) and Polyethylene (PE), are more common.