Discover how to add resistance to your model thanks to jigsaw structures.

Strengthen your 3D printed objects with specific structures

There are so many 3D printing materials, with various properties, that it is easy to find the right material for your project. When it comes to a mechanical part, the characteristics of the material are a central aspect to consider.

To help to strengthen the material you choose, there are tweaks and design features that give your object resistance and solidity.

To quote a few, jigsaw-structure, lattice structures, Voronoi patterns, topology optimization are some of the most known features to help your object gaining strength and resistance.

You can find useful resources on topology optimization on this blogpost.

What are Jigsaw-like structures

Jigsaw-like structures allow your model to gain strength by assembling several parts thanks to special joints.

By studying the nature, scientists have discovered interesting structure patterns to copy. Thanks to the biomimetic design, one can reproduce a turtle or oyster shell pattern.

Researchers have discovered that human bone structures can present similarities and be exploited to design strong 3D printed parts.

Jigsaw structures are great to reduce stress and increase strength on the assembly lines, especially for fragile materials like ceramics or glass.

Assembly to improve the model’s resistance

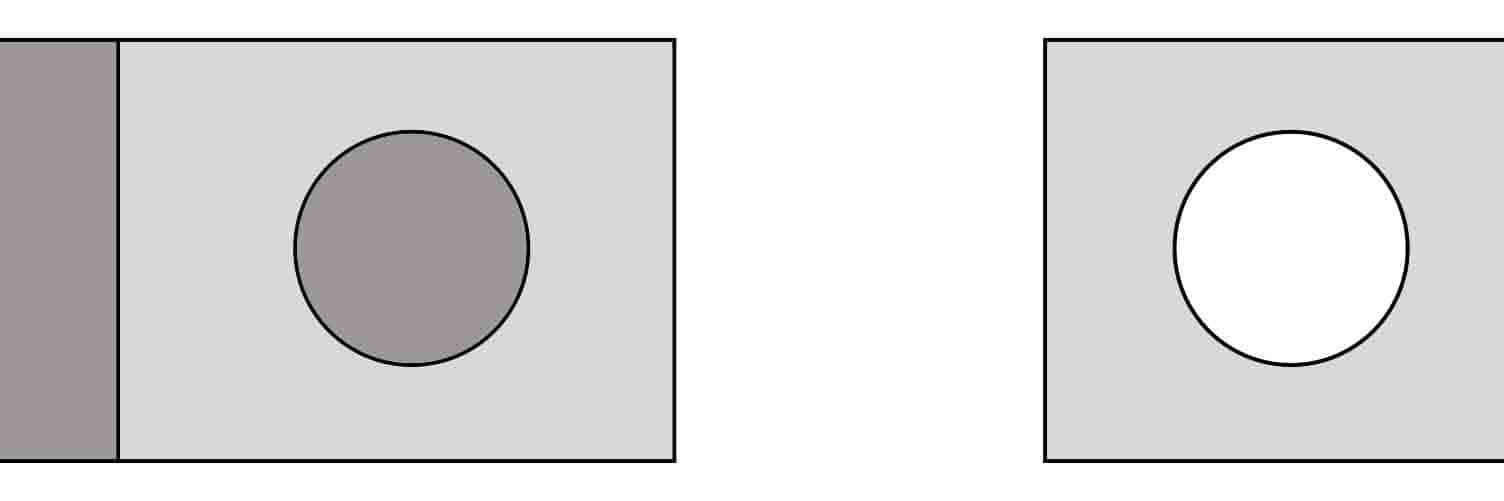

The strength of the jigsaw structure relies on the pattern of the joints that assemble the different parts. These joints can have various resistances and functions depending on their shape.

These are the most known joints used in manufacturing techniques for the part assembly:

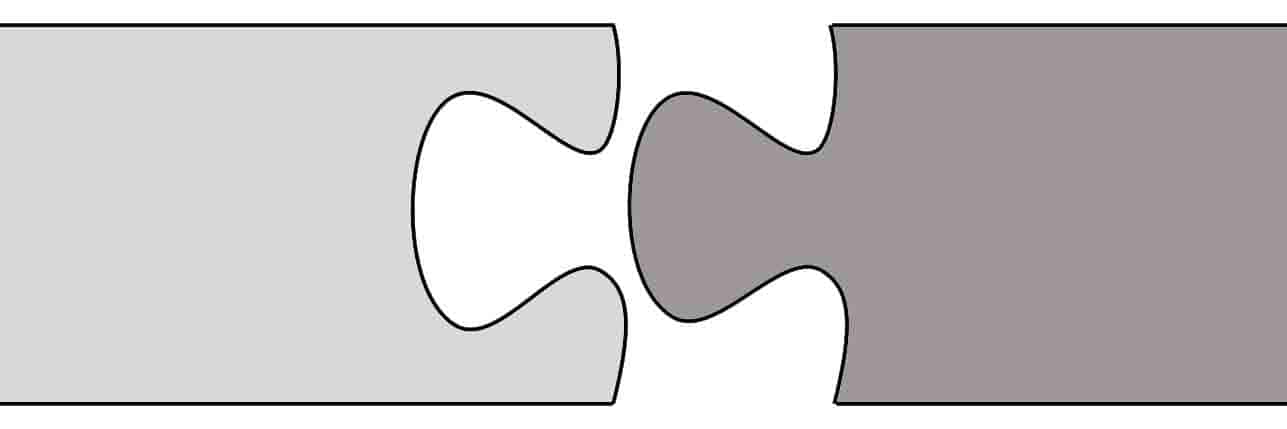

The jigsaw joint. Jigsaw joints can serve to joint two parts with a unique locking pattern.

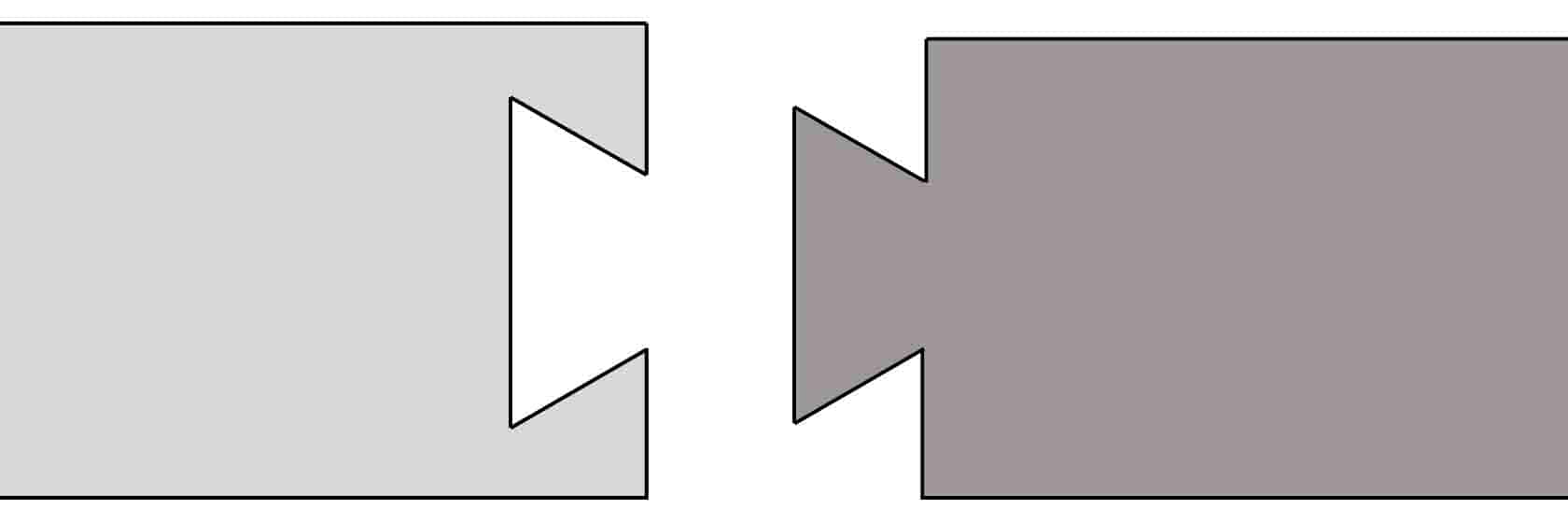

The dovetail joint. One of the most used in woodworking, dovetails can have various shapes and forms but allow to lock parts firmly.

The key joint uses a third part as a key to lock in the two parts together.

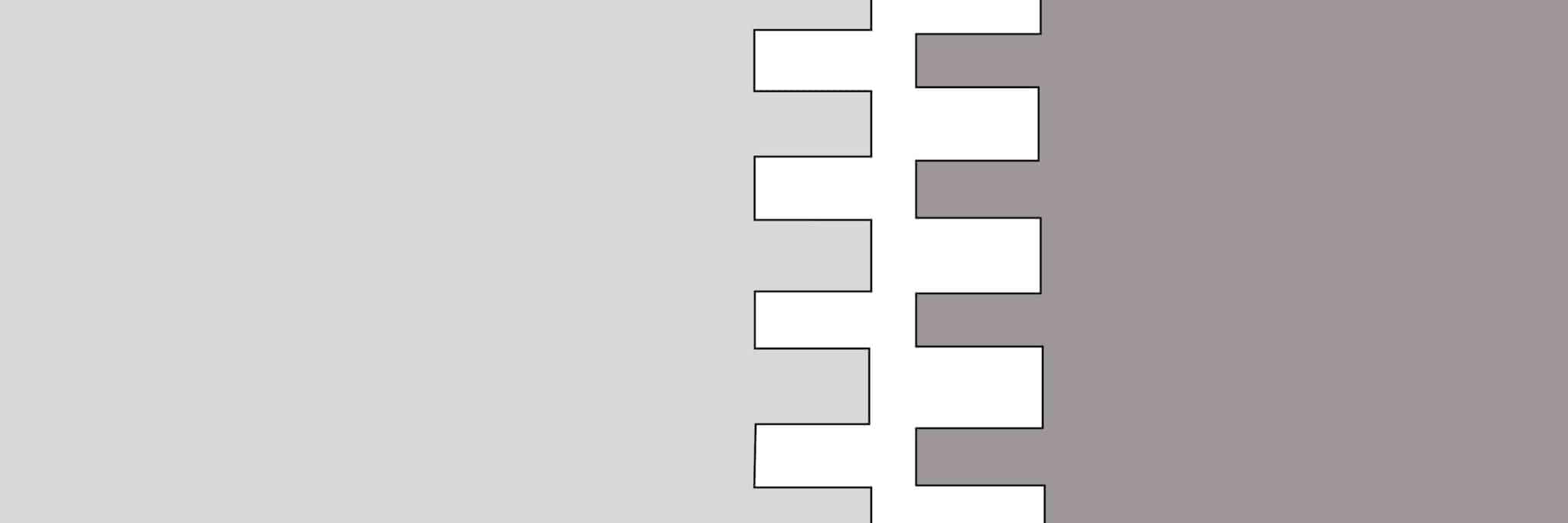

The fingertip joint is a type of joint which is more used in laser cutting than in 3D printing. It can be used for boxes and enclosures.

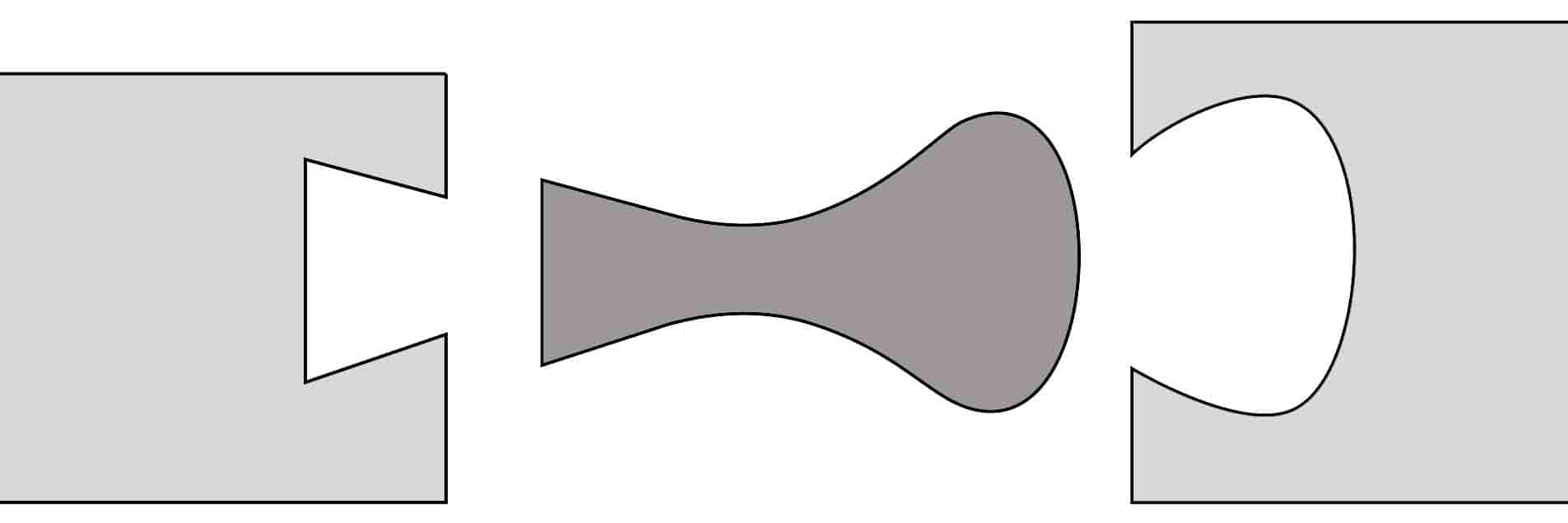

The tenon joint is a feature that allows connecting two parts with a hole and an embossed tenon.

Many variations of the joints listed above exist and are adapted to fit each unique designs.