3D printing has become a transformative technology across industries due to its design freedom, ability to produce complex geometries, and potential for mass customization. However, achieving reliable, high-quality results remains a challenge. Issues such as low part density, porosity, hot cracking, warping, or unstable support structures often lead to costly trial-and-error cycles.

This is where simulation software plays a critical role. By enabling engineers to predict microstructural evolution, optimize support structures, validate part performance, and simulate the printing process itself, simulations help reduce risk, cut costs, and accelerate innovation.

In this article, we explore the major categories of simulation tools for additive manufacturing (AM), from microstructural simulations to end-to-end process optimization, combining insights from leading industry sources.

1. Microstructure Simulations: Controlling Solidification & Defects

In metal additive manufacturing, the solidification of the melt pool directly affects part density, residual stresses, and mechanical performance. Advanced simulation tools allow engineers to model thermal gradients, fluid flow, and phase transitions at the micro-scale.

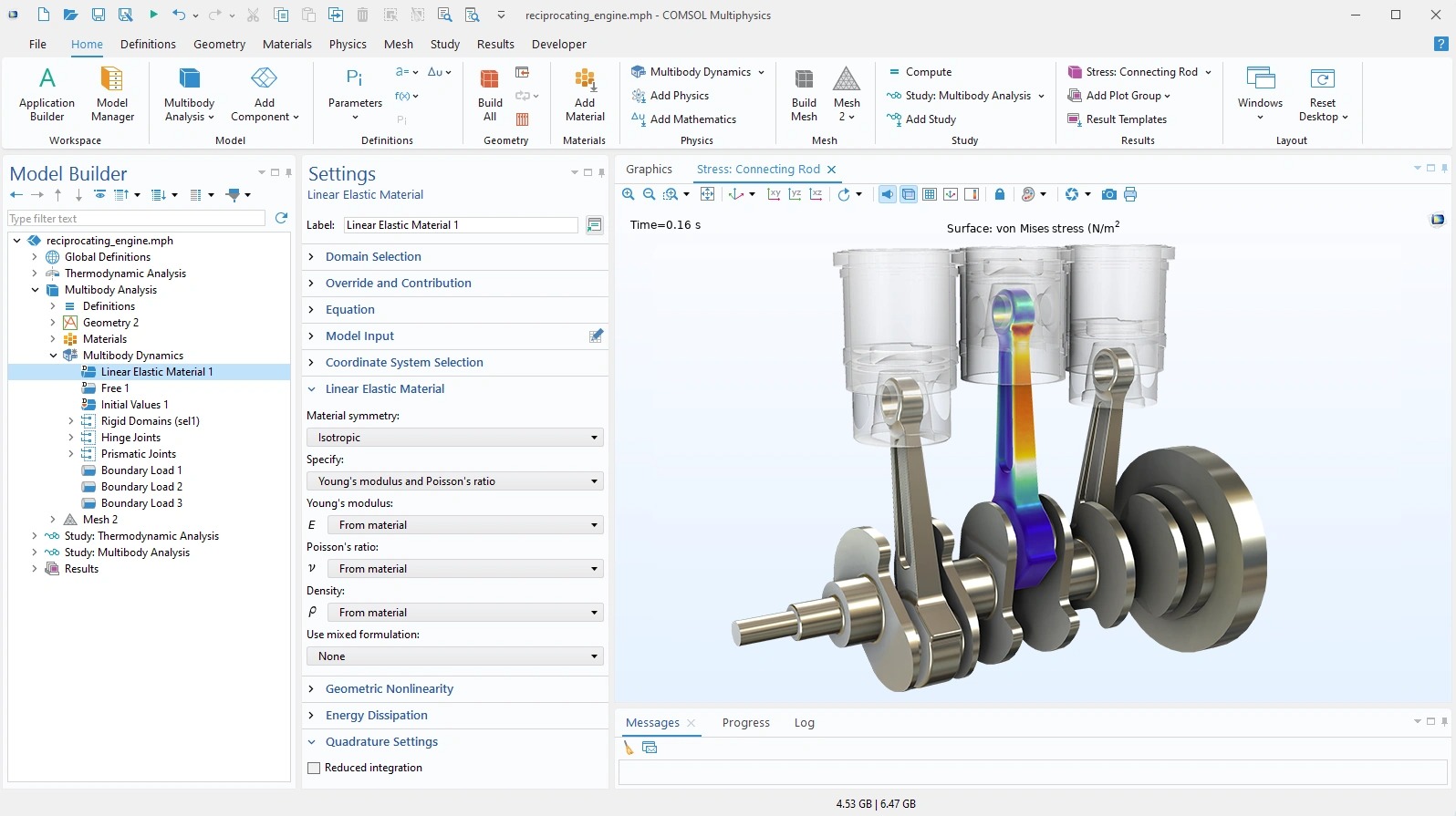

- COMSOL Multiphysics. A multi-physics simulation platform capable of coupling thermal, structural, and mechanical fields. COMSOL is widely used to model heat transfer and stress distribution, providing valuable insights into porosity, cracking, and deformation.

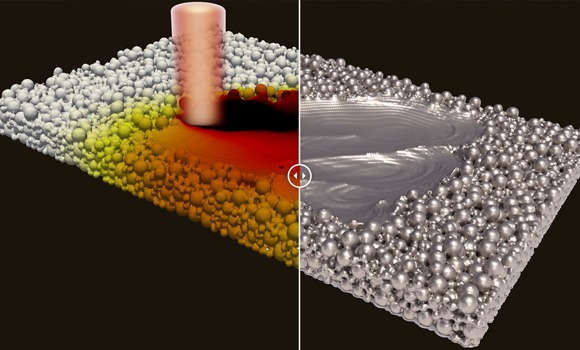

- Flow-3D & Flow-3D AM. Flow-3D applies computational fluid dynamics (CFD) to capture melt pool dynamics, fluid flow, and solidification. With its additive manufacturing-focused AM module, Flow-3D can simulate porosity formation, melt balling, and parameter sensitivities (e.g., scan speed or hatch spacing).

These tools allow researchers to adjust process parameters virtually, avoiding defects before they occur on the build plate.

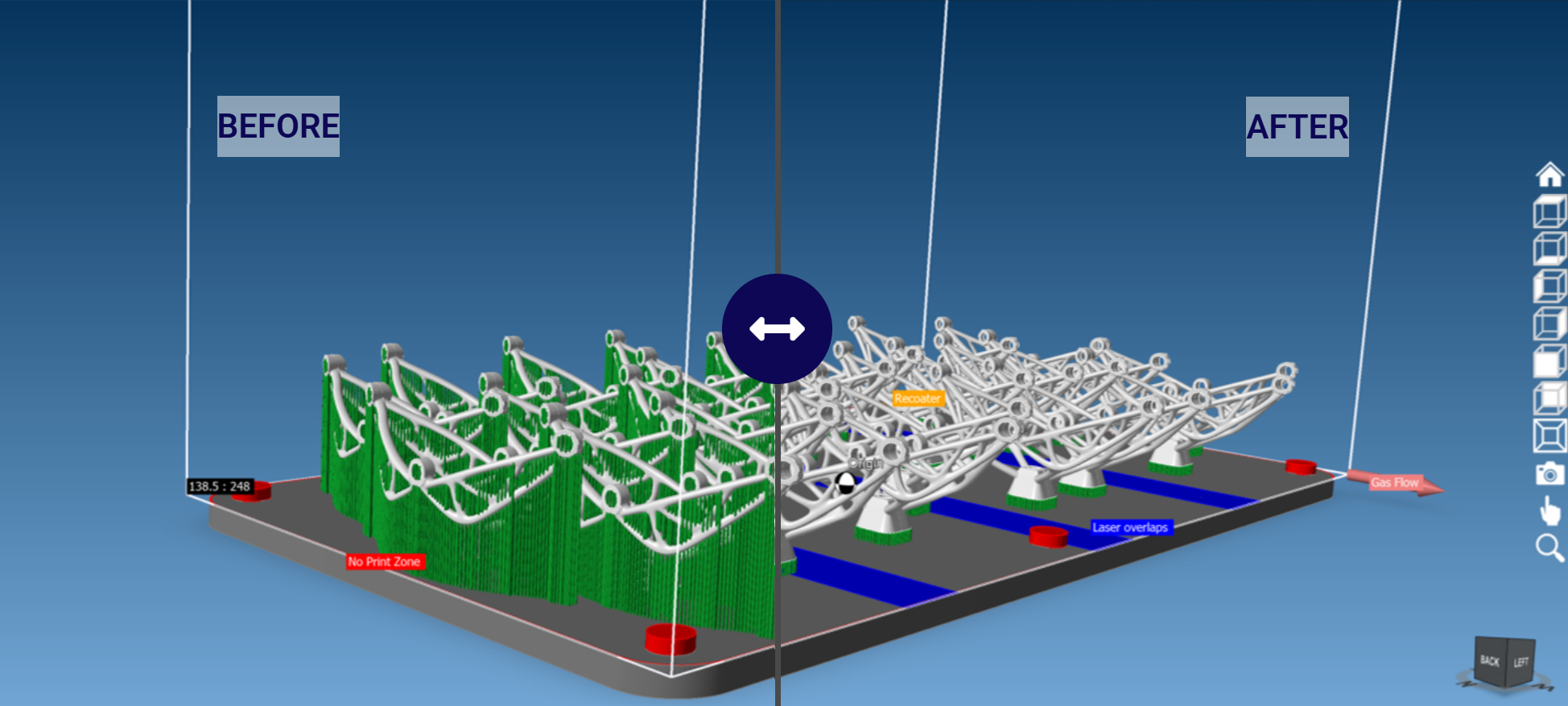

2. Support Structure Optimization: Stability Without Waste

Support structures are essential in 3D printing to maintain stability during builds, but they are also one of the biggest cost and post-processing burdens. Poor support design can lead to part failure, wasted material, and removal difficulties. Simulation helps strike the right balance.

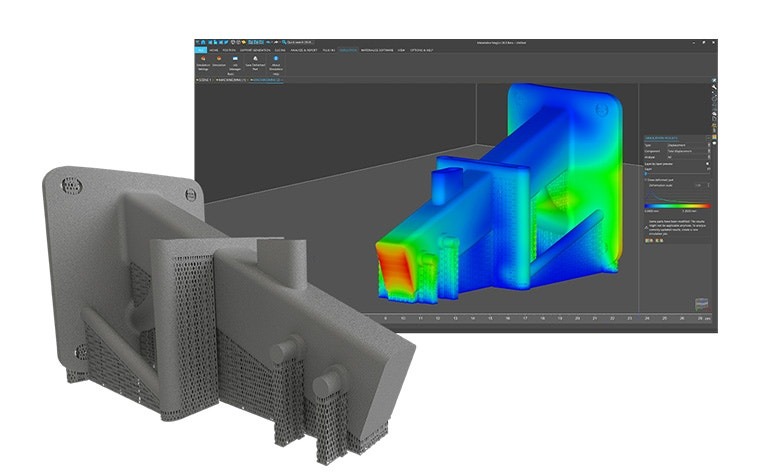

- Materialise Magics Simulation. An industry standard for stress and deformation analysis, allowing engineers to minimize residual stress and distortion.

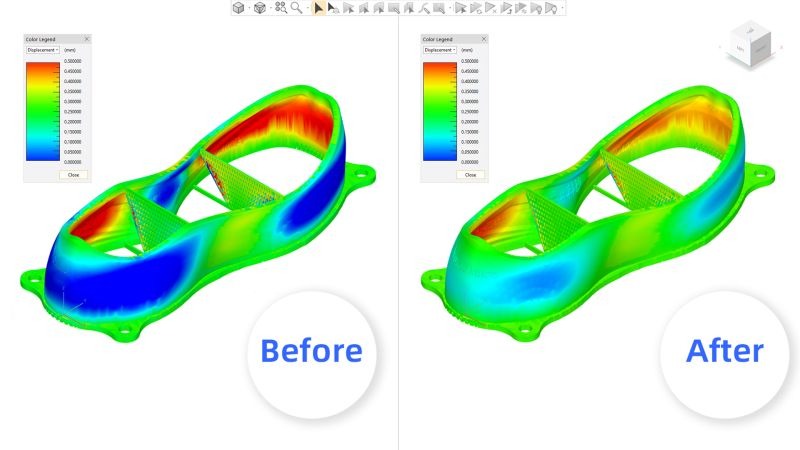

- VoxelDance Engineering (VDE). A rising Chinese solution that simulates supports as uniform dense structures and integrates material property libraries for accuracy. VDE is particularly strong in reducing warpage in enclosed and complex geometries.

- Genesis. Uses intelligent algorithms and historical data to identify risk areas in hollow or overhanging structures. Genesis helps designers minimize support volume and even achieve support-free internal features.

- Altair Inspire Print3D. Tailored to selective laser melting (SLM), it optimizes support structures with topology and manufacturability in mind.

- Simufact Additive (by Hexagon). A process simulation tool for metals that predicts residual stresses and final distortions, widely used in aerospace and high-value manufacturing.

Support simulations not only reduce material consumption and build time but also simplify downstream post-processing.

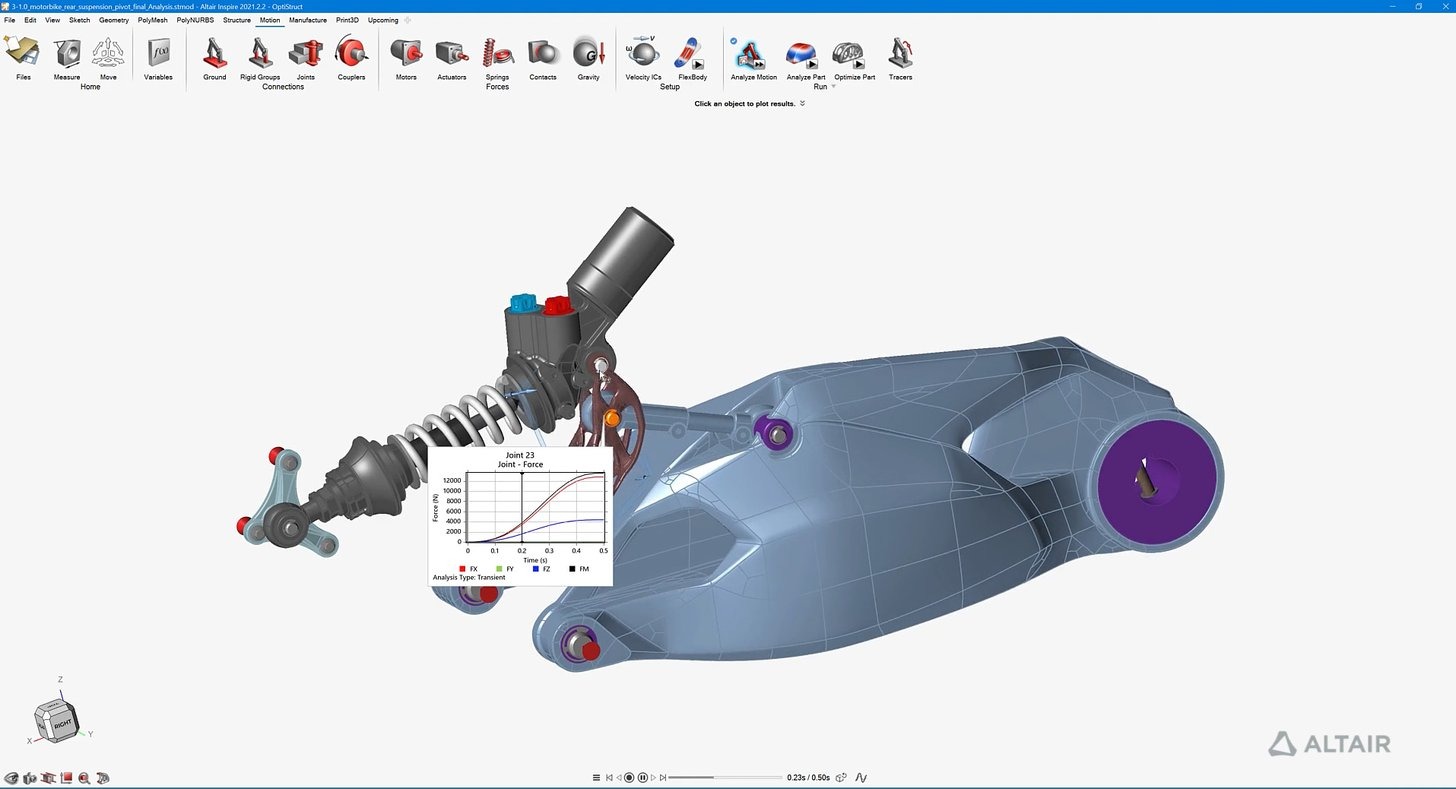

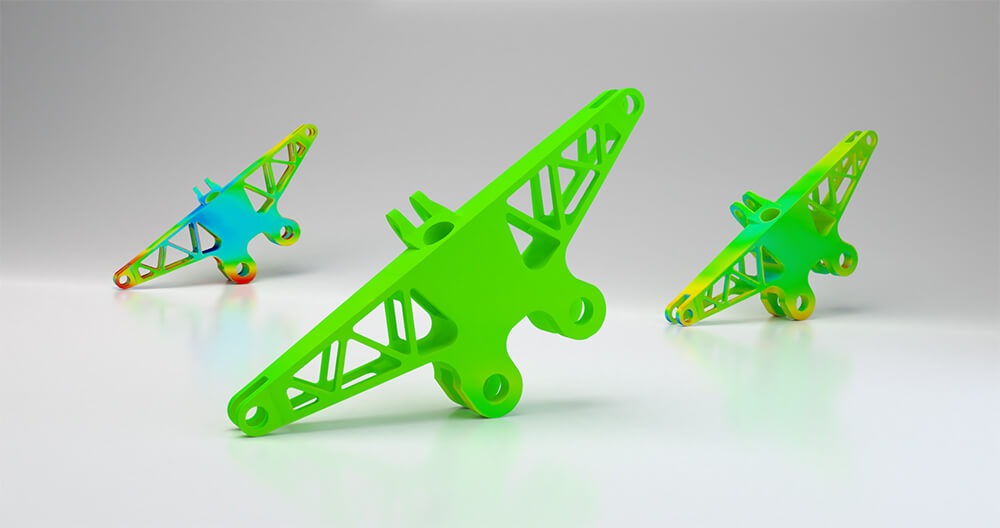

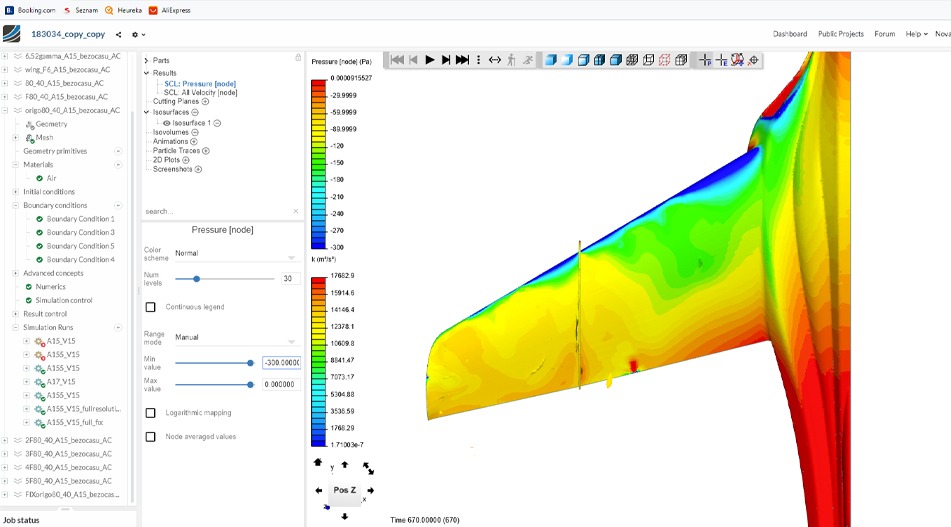

3. Functional & Performance Simulations: Accelerating Design Validation

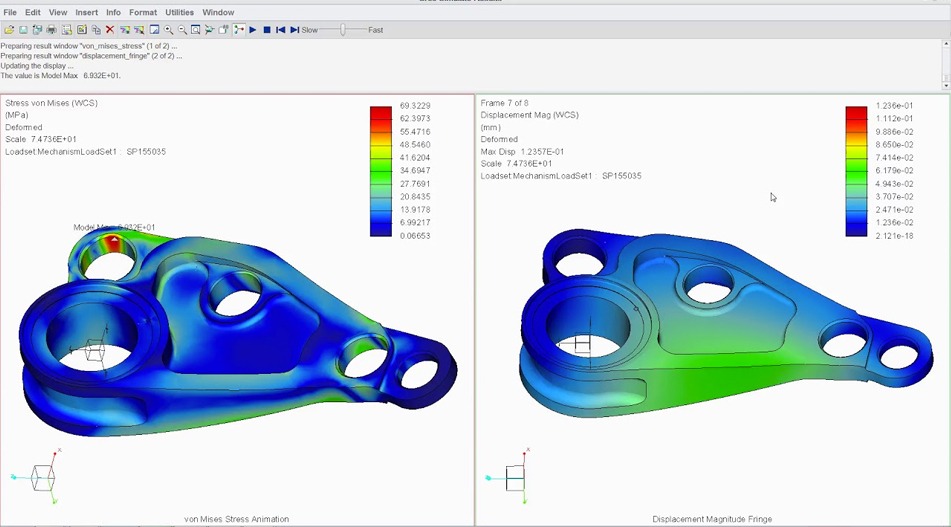

Beyond manufacturing, simulations also enable functional validation-ensuring that parts perform as intended under load, heat, or vibration. This shortens development cycles by replacing multiple prototype iterations with virtual testing.

- SimScale (Cloud CAE). A cloud-based platform that supports structural, thermal, and CFD simulations without local installation. Integrated with nTop Core, SimScale dramatically reduces model import and meshing time for complex lattices and heat exchangers.

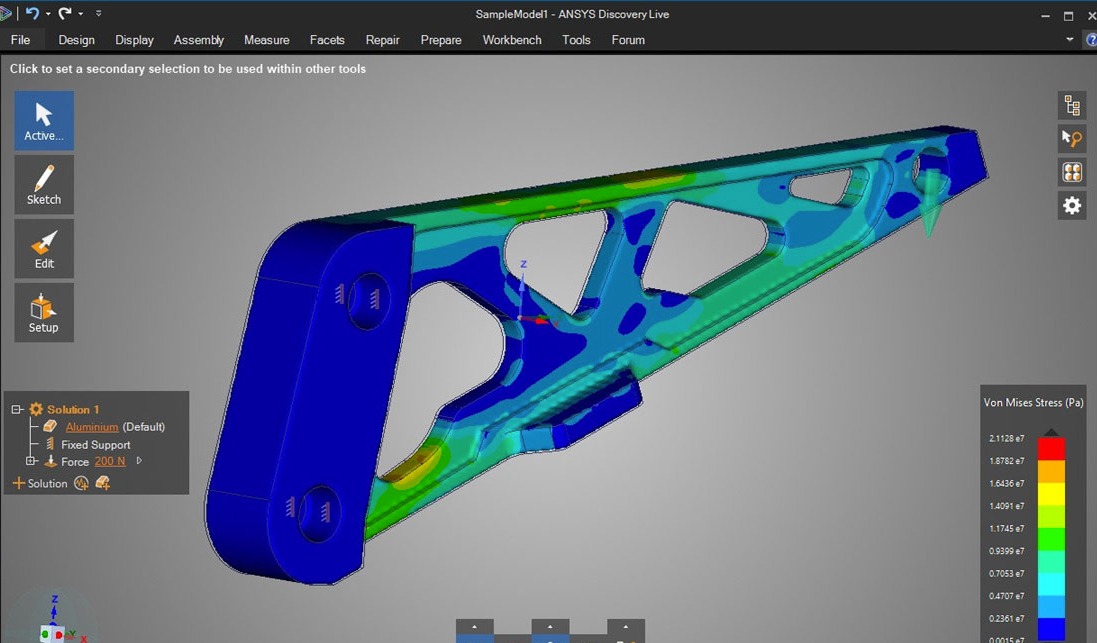

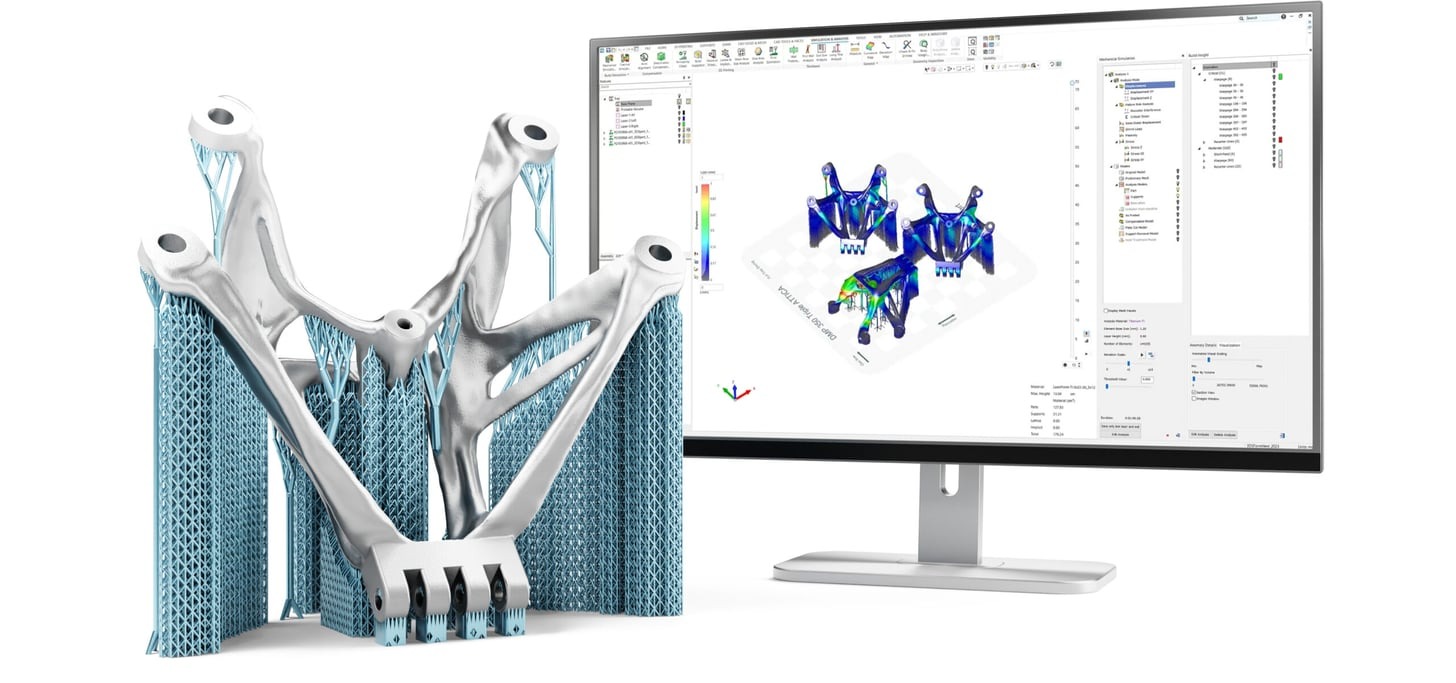

- ANSYS Discovery & Additive Suite. A powerhouse of multiphysics simulation, including process simulations for PBF, DED, and MBJ, along with build preparation, distortion compensation, and additive-specific analysis.

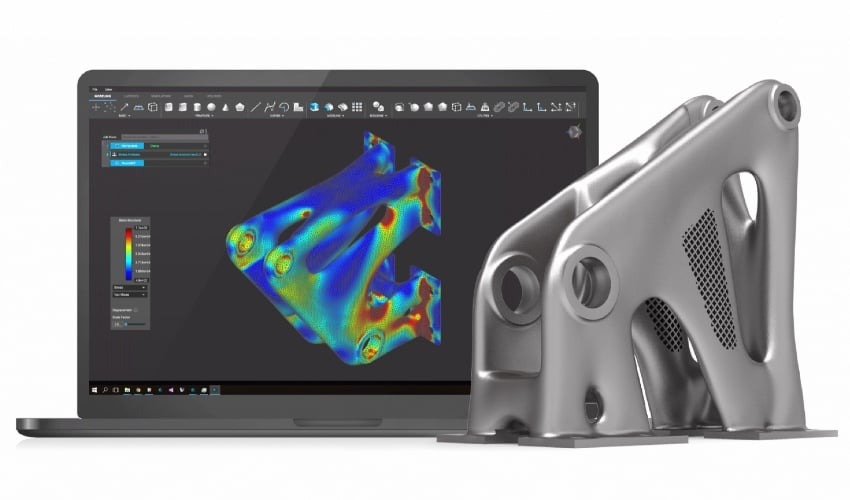

- nTop (nTopology). Known for lattice and topology optimization, nTop integrates mechanical and thermal FEA directly into design workflows, enabling lightweight and multifunctional designs.

- PTC Creo Simulate (with Ansys integration). Popular in the medical device industry, used for orthopedic implants and fatigue analysis.

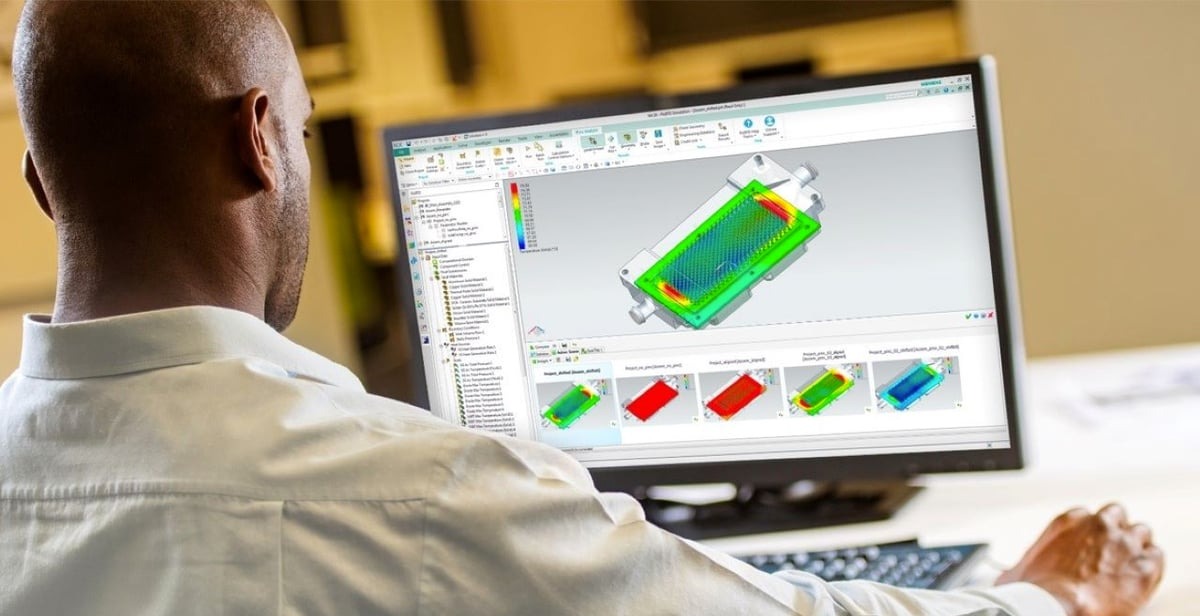

- Siemens Solid Edge & NX / Simcenter 3D. Offers a closed-loop workflow from design validation to print process simulation and quality assurance, making it a favorite in aerospace and automotive sectors.

These tools enable lightweighting, thermal management, and durability optimization while reducing expensive trial-and-error cycles.

4. Process Simulation: Predicting the Print Before Printing

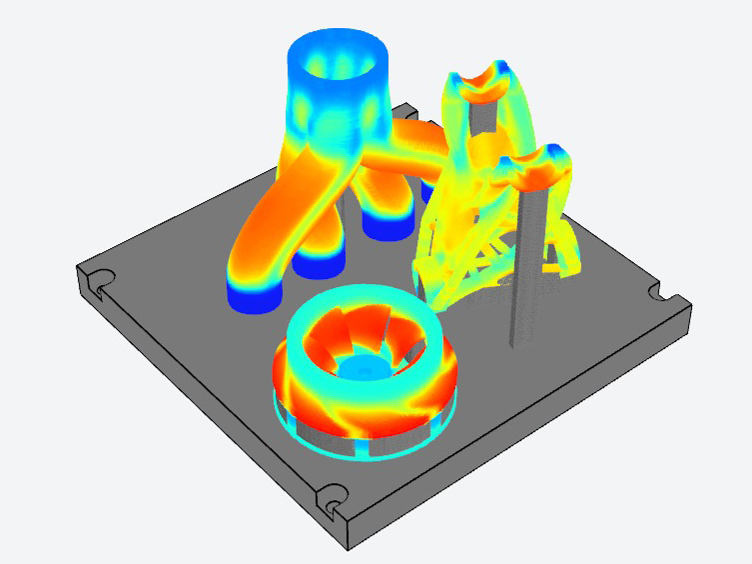

Distinct from FEA, process simulation software models the 3D printing process itself-layer-by-layer thermal cycles, powder spreading, laser paths, and machine-specific behavior. The goal: predict build failures before they happen.

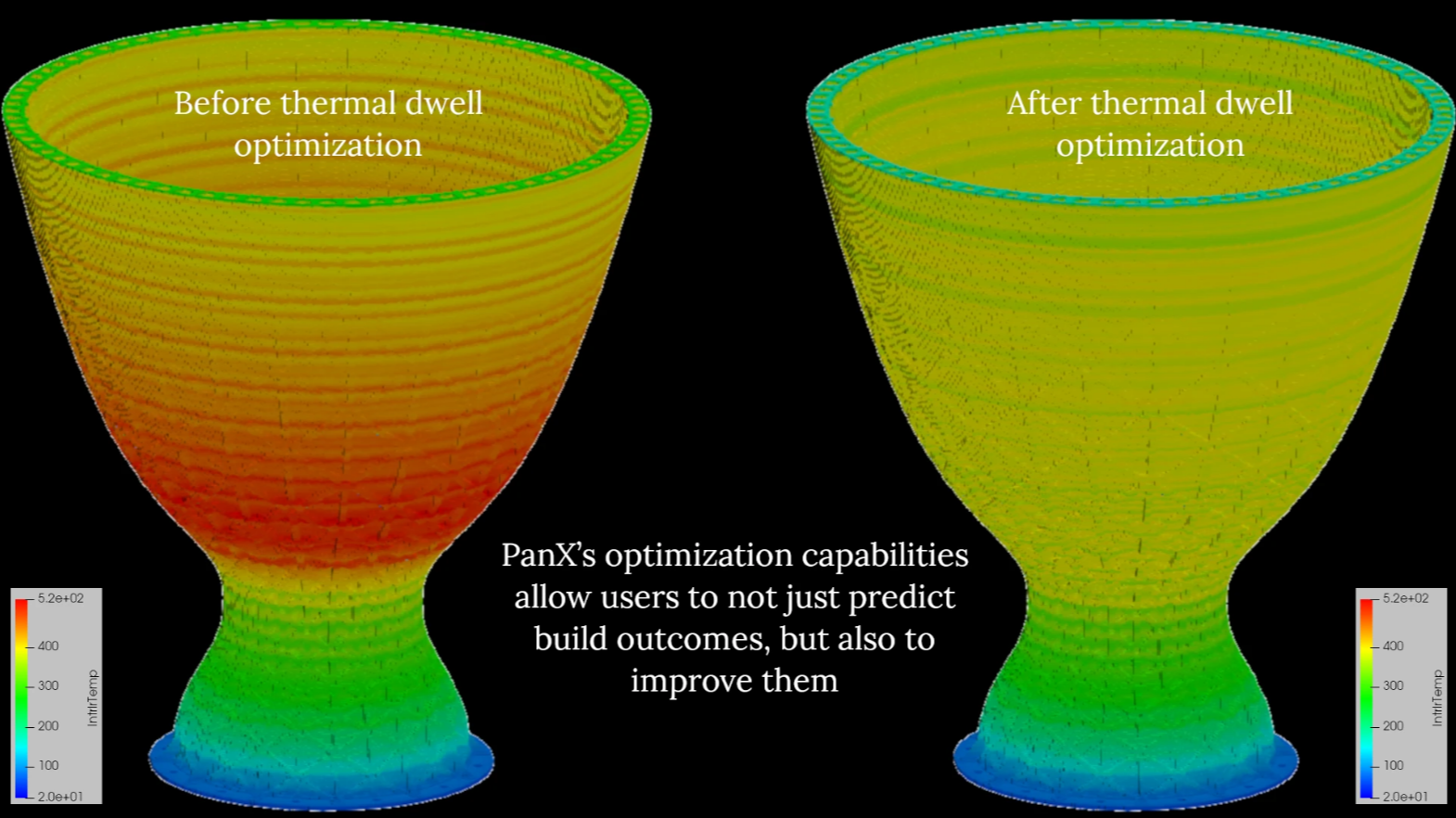

- PanX (PanOptimation). Uses a novel multi-grid modeling method, enabling thermal-mechanical simulations up to 100× faster than traditional FEA with modest hardware requirements.

- Oqton Build Quality (3D Systems subsidiary). AI-enabled monitoring and simulation suite with modules for build simulation, in-situ monitoring, and anomaly inspection.

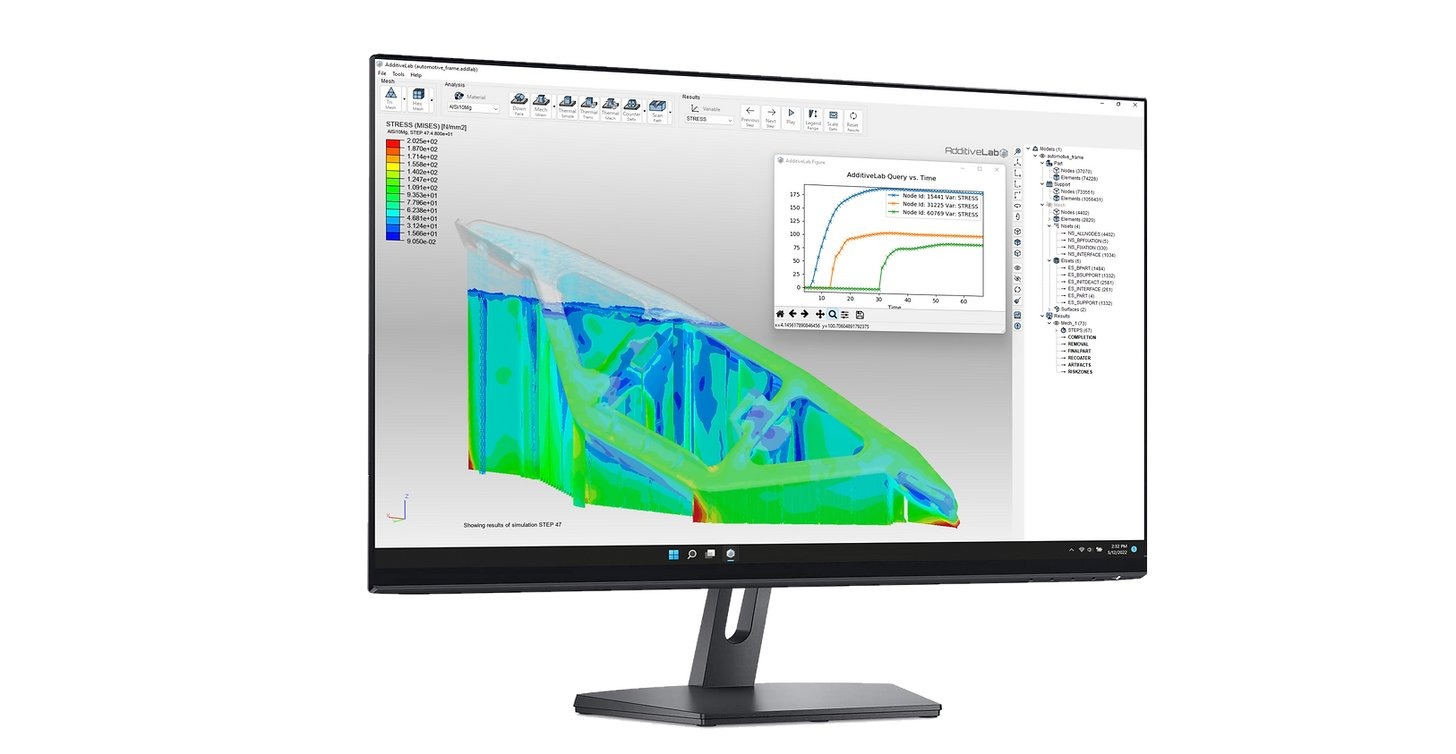

- AdditiveLab. A startup tool predicting overheating, distortion, and melt pool defects. It also offers a Python API for researchers to create custom simulation workflows.

- 1000Kelvin Amaize. An AI-powered correction engine integrated into EOS LPBF systems. It analyzes scan strategies and autocorrects recipes to prevent defects.

These process simulations act as “virtual print previews”, drastically improving first-time-right success rates.

5. Industry-Wide Impact & Future Outlook

Simulation in additive manufacturing is no longer a luxury-it’s becoming an industry standard. By combining microstructure modeling, support optimization, functional testing, and process simulation, engineers can:

- Reduce defects and scrap rates

- Cut trial-and-error time and costs

- Enable lightweight, high-performance designs

- Achieve repeatable, certifiable quality

With AI-driven tools like 1000Kelvin and cloud-based solutions like SimScale, simulation is becoming more accessible, faster, and smarter. As domestic solutions (like VoxelDance in China) continue to rise, the ecosystem is expanding globally.

Conclusion

Simulation has become the accelerator of 3D printing adoption, moving the industry from trial-and-error-driven to prediction-driven manufacturing. From controlling melt pool physics to optimizing lattice structures and monitoring real builds, today’s software makes additive manufacturing more reliable, efficient, and scalable than ever.

As industries like aerospace and healthcare demand lightweight, safety-critical, and customized components, simulation-enabled additive manufacturing is poised to become a cornerstone of next-generation production.