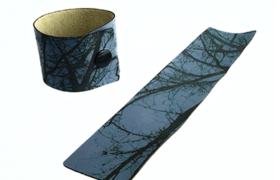

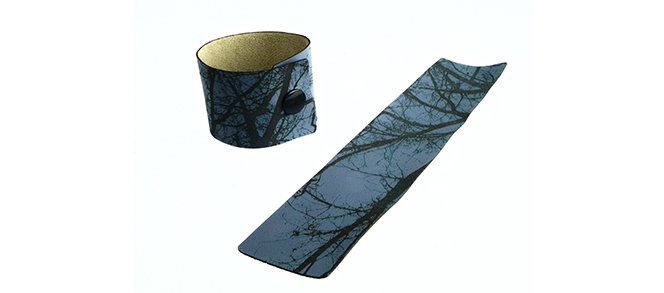

Leather is a highly adaptable material that is ideal for laser technology, whether you are working with it in artificial or genuine form. With laser engraving leather, you can give belts, wallets or bracelets an individual touch of elegance. Here you will find some of our tips and tricks for processing leather with a laser engraving machine.

Basics for processing all types of leather

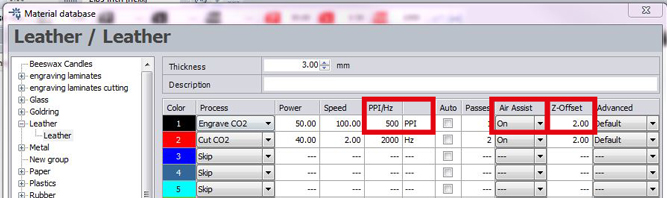

To achieve the best possible engraving result, activate your systems Air Assist and work with a resolution of at least 500 ppi. Both settings can be adjusted in the material database in JobControl.

Genuine (organic) leather

Genuine leather is a material that is natural in composition and is offered in various forms that all react differently to laser processing. Therefore, it is difficult to establish exact common rules for all types.

Suggestions for proceesing all leather types:

- If your workpiece begins to deform during laser processing, we suggest reducing the laser power.

- If you are looking to clean your leather after processing, we do not recommend the use of any cleaner since the leather is a natural material. Many cleaning agents are too aggressive and may cause spots to form or the leather to dry out. To be safe, always test a cleanser in a small or hidden area of the workpiece, or use a test strip first.

Imitation (synthetic) leather

- Synthetic leather will usually have a fabric layer that makes it stable and easier to handle.

- Cleaning a workpiece is easy with the use of dampened tissue or a sponge.

- When engraving imitation leather, defocusing the laser will allow for a lighter color change to appear. This setting can be changed via the Z-Offset in JobControl® (see the accompanying screenshot above).