PLA plus is filament that’s supposedly a better version of the beloved PLA. But is it? Learn all about this mystery material!

What Is It?

While PLA is a great material to print with, it has a few downsides. For example, PLA has always been criticized for being just a little too brittle but also for absorbing some moisture.

Most would probably say the next step up from PLA is either PETG or ABS. In general, both are stronger and more resistant than PLA, but neither are as simple to print with.

PLA plus sort of occupies the sweet spot between PLA and the next step up, or at least, it’s supposed to. It’s a confusing topic, but luckily, we’re here to help. In the following paragraphs, we’ll go into more detail about the mystery that is PLA plus, discussing its formula, different names, prices, and more.

At the very end, we’ll reach a conclusion on whether or not PLA plus is worth the extra money.

Mysteries, Debunked

Naming

Although we’re using the term “PLA plus”, not everything belonging to the category of “PLA plus” is the same.

Think of “PLA plus” as a general name for a large group of improved PLA filaments. Within this group, manufacturers use a variety of product names as a strategy for marketing a product, hence not all PLA plus filaments are called the same thing.

For instance, brands like eSun, Filiform, and Kodak use the slight variation “PLA+“. On the other hand, ColorFabb refers to its superior blend of PLA as “PHA“, and several others use “Pro PLA“.

Usually, different names are only there as a marketing strategy, but in some cases, they do actually represent different polymer blends. The best example is PHA, which stands for “polyhydroxyalkanoate”.

Marketing

Sadly, there are some cases where PLA plus filaments don’t perform as they should. The possible answer as to why lays in marketing. Hungry for new customers, there’s a chance some manufacturers just stick the name “PLA plus” (or some variation) to a generic PLA product. Luckily, this is something that probably won’t happen if you’re buying from a well-established brand.

For example, there’s a slightly negative tone around Sunlu’s PLA Plus on forums for not performing as expected. It could be the case of a few people getting bad spools, but it could also mean it’s not a “proper” PLA plus.

In the end, it’s always a good idea to read reviews and double-check with forums before making the purchase.

The Secret Formula

There’s no single formula for PLA plus. Manufacturers either have their own formulas and mixtures or they source them. In the majority of cases, manufacturers stay tight-lipped about their formulas. However, with some digging around, one can discover a few things.

Because PLA plus should be less brittle and absorb less moisture than regular PLA, there’s a chance it contains a bit of TPU, which helps it achieve better properties.

- ColorFabb is one example of a manufacturer that created its own blend for a better PLA. As mentioned earlier, they call it PHA (polyhydroxyalkanoate). It’s generally similar to PLA but tends to offer more strength. It’s manufactured from a PHA-reinforced PLA blend.

- 3DFuel and Push Plastic are great examples of manufacturers sourcing the mixtures. The filaments we’re talking about are 3D-Fuel’s Pro PLA and Push Plastic’s “High Heat PLA”. On both manufacturer’s websites, it’s clearly stated that it’s made from NatureWorks’s 3D870 Ingeo PLA.

- This blend is basically a high-quality PLA grade that’s manufactured by NatureWorks and distributed into a large range of industries to be transformed into products, among which is the 3D printing industry.

Compared to PLA

Print Settings

Most PLA plus filaments print at slightly higher temperatures than regular PLA. For example, eSun’s regular PLA prints at 190-210 ℃, while their PLA plus prints at 205-225 ℃.

Not every filament is the same, and this is why there isn’t a single temperature rule for every PLA plus. The majority is somewhere between 200 and 230 ℃.

Performance

Let’s face it, performance is the only reason why one would spend an extra buck on PLA Plus. So, how is it when compared to PLA? Well, most of the time PLA plus does indeed tend to show better results in tests for stiffness and resistance to higher temperatures, although not much.

The most noticeable performance upgrade is, of course, the stiffness PLA plus provides to parts. Parts made with regular PLA don’t tend to flex, instead snapping quickly when under pressure. PLA plus parts, however, do tend to show better resistance to pressure as they flex better and withstand pressure for a longer time.

Pricing

Better material properties come with a higher price to pay. Naturally, prices depend on the manufacturer, but in most cases, expect to pay between $5 and $15 more than you would for the same-sized spool of regular PLA.

For example, 3D-Fuel’s Standard PLA costs roughly $30, while the superior Pro PLA costs roughly $40.

Color Options

Once again, the answers depend on manufacturers. Some offer a limited range of colors for PLA plus, while others truly have many to choose from.

Take eSun and 3D-Fuel as an example. eSun has over 20 color options for PLA plus, and 3D-Fuel only has 7.

Compared to Other Materials

PETG

Once again, this is dependent on the manufacturer. Still, PLA plus is, in most cases, a little easier to print with. And in terms of temperature resistance, PETG is most likely to take a win in most scenarios.

PETG does require higher printing temperatures and tends to be a little trickier to get perfect in terms of the settings profile. It’s always been known for the great stiffness it provides. If you’re really after some strong parts, PETG is most likely to be a better choice for you.

On the other hand, if you don’t really need those strong parts but still want to print parts that are stronger than PLA, go for a quality PLA plus.

ABS

There’s a bigger gap between PLA plus and ABS than with PLA plus and PETG. ABS is a tricky material to print with, but it offers incredible temperature and impact resistance and is more flexible than PLA plus.

Let’s not forget that ABS also emits fumes when printing, but if temperature and impact resistance are your absolute priorities, ABS is a better choice despite it being more challenging to print with.

Final Thoughts

Finally, now that we’ve explained all there is to know about PLA plus, it’s time to discuss the value proposition.

If you’re mainly printing aesthetic and non-functional models, normal PLA will work just fine since blenders are anyway getting better and better. However, if you’re printing parts that need to resist loads, PLA plus is certainly worth a try. After, you can easily decide for yourself if the extra strength is worth your money.

There’s no straight answer to the question of worth. It highly depends on which make of filament you choose, but also on your budget and printing interests.

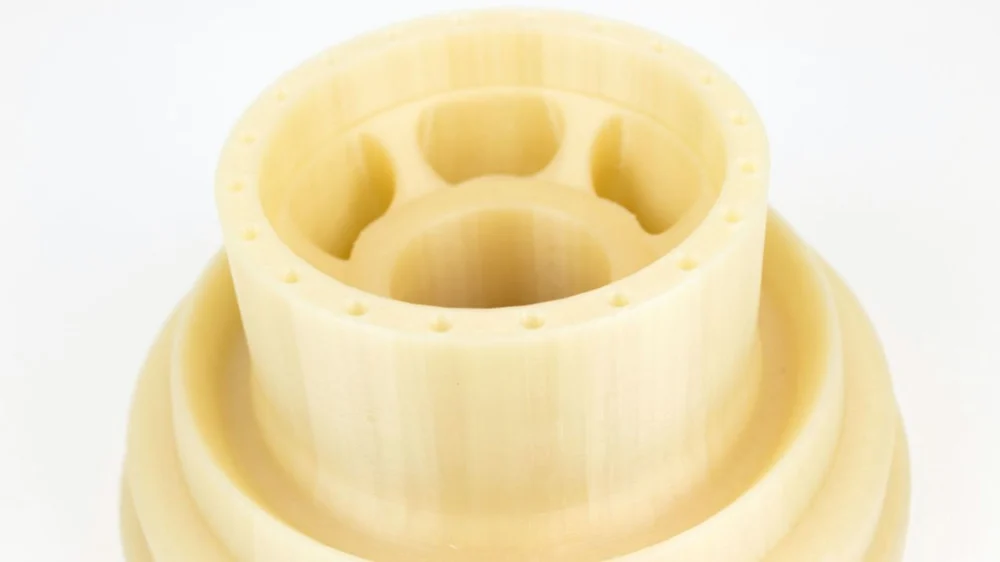

(Lead image source: Think Making via YouTube)