Overmolding is not a new manufacturing technology, but there is still some confusion about how to design for the two-part process. One of the largest areas to consider? Bonding. A number of materials can be used to overmold components together, but without a chemical bond or mechanical interlock, some overmolded parts won’t stand the test of time.

Chemical Bonding

This bonding process involves two chemically compatible materials that are molded together to form a strong bond with each other. It’s important to note that not all materials play well with one another. The compatibility chart below indicate whether a chemical or mechanical bond is recommended for key thermoplastic and thermoset materials.

Mechanical Interlocking

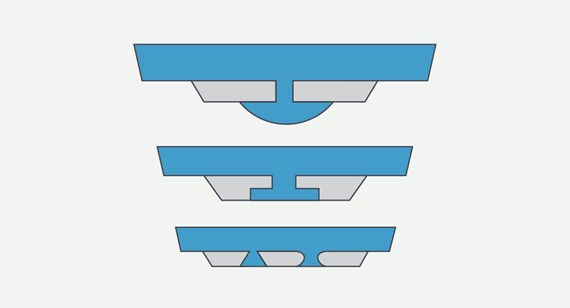

What happens when your materials are not compatible, the desired bonding strength cannot be achieved, or you want to ensure your materials don’t peel apart from repeated use? This is where designing a mechanical interlock, which physically holds the overmolded material to the substrate, makes sense. There are many ways to design these into parts (see example), so discuss the options with your manufacturer.

Chemical Bonding Compatibility

| SUBSTRATE MATERIAL | ||||||

|---|---|---|---|---|---|---|

| OVERMOLD MATERIAL | ABS LUSTRAN | ABS/PC CYCOLO C2950-111 | PC LEXAN 940-701 |

PBT VALOX 357-1001 |

PP PROFAX 6323 | NYLON 66 ZYTEL 103 HSL NC010 |

| TPU – Texin 983-000000 |

C | C | C | C | M | M |

| TPV – Santoprene 101-87 |

M | M | M | M | C | M |

| TPE – Santoprene 101-64 |

M | M | M | M | C | M |

| LSR – Elastosil 3003/30 A/B |

– | – | M | M | – | M |

| TPC – Hytrel 3078 | C | C | C | C | M | M |

| TPE-Versaflex OM 1060X-1 |

C | C | C | M | M | M |

| TPE-Versaflex OM 6240-1/td> |

M | M | M | M | M | C |

| TPE-Versaflex OM 6258-1 |

M | M | M | M | M | C |

| TPE-Versaflex OM 1040X-1 |

C | C | C | M | M | M |

M = mechanical bond recommended

C = chemical bond

If you have further questions regarding rapid overmolding at FacFox, contact one of our applications engineers at info@facfox.com.