As SLA uses resin and not molten thermoplastics, the effect of material shrinkage and warping is much less severe than in filament-based printing techniques. However, that doesn’t mean SLA isn’t without its own deformation issues. The photopolymer will shrink during the UV curing process, and results in wrapped edge, deformation and bad dimensional precision.

Introduction

People usually consider the shrinkage of material only happens in the curing process. It’s not the truth. Indeed, it also troubles the craftsman during the printing process.

When you are making an iPhone case or anything fits together, their sizing is crucial. The shrinkage rate differs in different materials, like the most commonly used plastic for personal 3D printing, ABS will shrink approximately 8% after cool down, and PLA only shrinks by around 2%. This is the size-changing brought by the material shrinkage, which is not the case we want to discuss.

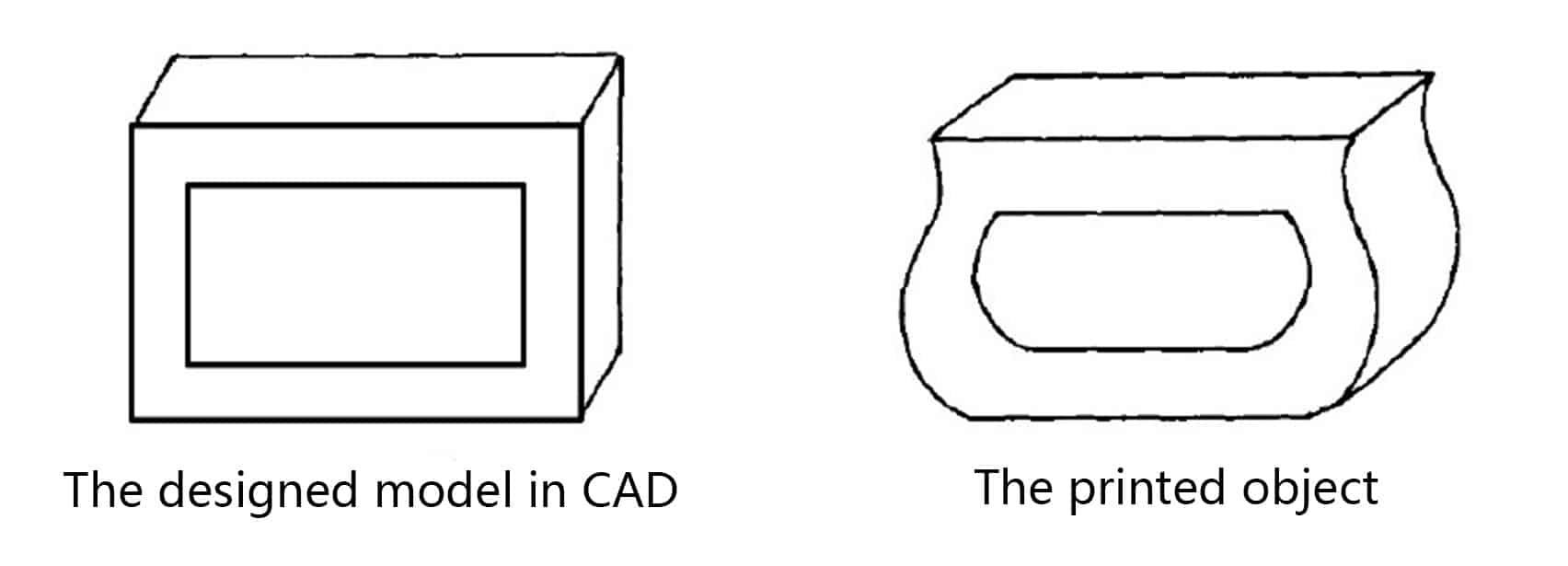

We are trying to figure out how material shrinkage results in deformation and the discrepancy between your design in CAD with your print. If you already encountered such a problem or are just worry about that, this article worth your reading.

Two Reasons for the Material Shrinkage

Thermal expansion and contraction

SLA is based on the photopolymerization of a liquid resin material to form hardened plastic. This is an exothermic reaction, meaning a lot of heat is generated during the photopolymerization step.

The sudden temperature increase and the subsequent cooling right after polymerization can result in significant warping and deformation, especially in designs that have not properly accounted for this phenomenon.

Thermal expansion and contraction generate stress uniformly along all three axes. To avoid deformation or cracking of the finished print, it is crucial that the print is designed so that there is no buildup of the stress due to thermal expansion and shrinkage.

This can be done in a number of ways, such as by designing walls to have a uniform thickness all throughout. Stress buildup can also be avoided by having smooth corners where two walls intersect, instead of sharp ones.

The change on the molecule level

3D printed photosensitive resin materials will shrink during the printing and curing process, usually, the linear shrinkage is about 3%.

From the perspective of polymer chemistry, the curing process of photosensitive resin is a process of transforming from short small molecules to long-chain macromolecular polymers, and its molecular structure changes greatly. Therefore, shrinkage during curing is inevitable.

Explained from the perspective of polymer physics, the small molecules in the liquid state have Van der Waals force, while the solid-state polymers are under covalent bond distances between their structural units. The covalent bond distances are much smaller than those of Van der Waals forces. , so when the liquid prepolymer solidifies, it will inevitably cause the volume of the part to shrink.

The Shrinkage during the Printing Process

The shrinkage of the lower part

When the process starts, the laser “draws” the first layer of the print into the photosensitive resin. Wherever the laser hits, the liquid solidifies. But the photocuring reaction is actually a long process, lasting for nearly one week.

It always happens that the last layer is not hardening enough, but the laser is already solidifying the adjacent upper layer. The below photopolymer will shrink and pull the upper material, which changes the shape or causes a wrapped edge. All the layers shrinking, the total deformation of the object will be considerable.

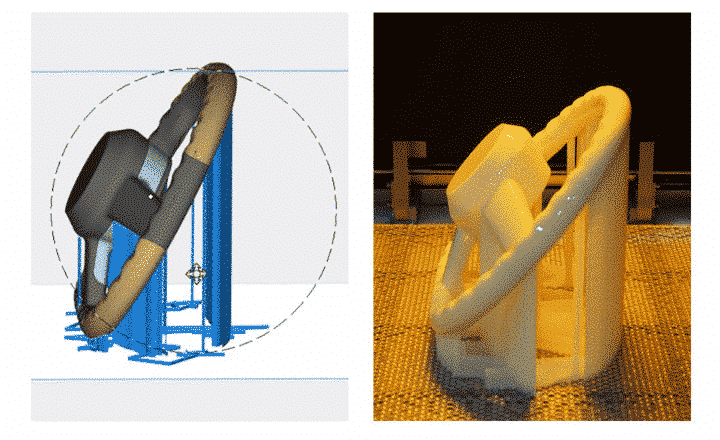

If you print a single object, the shrinkage will be more severe, cause the laser to pass every layer quickly and leave less than 1 second for the solidification. Our suggestion is to print many objects simultaneously, which needs 1-2 seconds for each layer, sufficient for the layer to harden.

The shrinkage of the upper part

The second circumstance usually accompanied by producing thick layers and solid objects. When the bottom of an object have hardened, the upper part is still under shrinking, the stress will pull the lower part and cause wrapped edges. Some objects whose upper and lower parts have quite different structures also appear shrinkage during the printing process. It’s inevitable and our advice is printing more test parts.

The Shinkage during Post-Processing

Although the resin is cured by exposure to the laser, it does not become fully cured in that brief instant. The material will only reach full strength once it is placed in a UV curing oven during post-processing. That’s not to say that before post-processing the material is weak or uncured, it’s just not up to its maximum load-bearing state. For well-supported areas of the part, this is not an issue, but if there are sections that long, thin or lacking in support, some sagging can occur.

This sagging is usually microscopic, but because it happens one layer at a time the effect can be cumulative, resulting in noticeable dimensional discrepancies. This effect is affected by the resin used. Some stronger materials will not suffer from this at all, but flexible materials are particularly prone to the issue. This is why support material is so important in SLA, and if the software does not place the supports in the most optimal way accuracy will be seriously compromised.

Supports are usually generated at a 45° angle to the part so that the intersecting surface will be minimum.

A New Photopolymer with only 0.7% Shrinkage Rate.

Dymax’s latest Bomar® BR-970H is a revolutionary stain resistant oligomer with high modulus, ideal for 2D and 3D inkjet printing applications, as well as graphic art applications. With a shrinkage rate as low as 0.7% during cure, BR-970H is perfect for maintaining quality aesthetics on 3D printed parts.

BR-970H also offers rapid cure and non-yellowing properties for higher optical clarity, and color stability for premium performance. Additionally, its low water absorption of 0.15 makes it particularly appealing for 3D printed parts that are exposed to high-humidity environments or washed with water-based solutions.