Choice is good. In most cases, the more options you have, the better your chances of getting exactly what you are looking for. But with more choices, the job of finding a perfect fit for what you need gets more complicated.

This dilemma is certainly the case when it comes to product design and development, and specifically, when you are choosing materials when designing for machining. Material options abound. Your design is custom and you know your needs better than anyone else. With this “over-choice” challenge in mind, here are some ways you can use your knowledge of your part’s function or application to narrow the universe of material options, simplify your search, and get the best possible end result:

- Determine needed requirements for your part’s function

- Identify common materials used for machined parts

- Consider related secondary processes

- Use prototypes

Prioritizing Your Part’s Requirements

The first step is to prioritize your requirements. Start with the must-haves and work your way down to identifiable nice-to-haves. Chances are good that this process will reduce your material options to a workable number and help you make a more informed choice regarding materials. At FacFox, we use sophisticated software to evaluate your CAD design and produce a quote, but we cannot know your application. You know the conditions in which your part will function and/or how it is intended to fit into an assembly. That’s key information to know as you develop your part. Accordingly, some of the factors that may figure into your list of priorities include:

- Environmental: For many, this will be an absolute top-of-the-list requirement. Environmental factors can include heat and cold resistance, flame retardance, or UV and chemical tolerance. Depending on the application, your materials may have to be food grade or medical grade. Consider the full scope of a part’s application. For example, parts for a medical device may have to tolerate the extreme high heat of an autoclave or harsh chemical sterilization between uses.

- Electrical: This can cover a range of application-dependent factors. A part may need to conduct or insulate. It may need to dissipate static. In any of those cases, choosing the right metal or plastic resin will be critical.

- Mechanical: Strength comes in many forms. A part may need to fall anywhere on a continuum from rigid to flexible. It may require tensile strength or compressive strength, or be able to resist impact. It may have to resist wear or provide lubricity in order to function as a bearing. There are materials that meet these requirements, some more effectively than others.

- Cosmetic: In many cases, cosmetics are a secondary consideration; in others they can be essential. The right materials can produce a transparent or translucent part. Some materials—typically plastics—can be supplied in a variety of colors, while metals can be colored using secondary processes. Similarly, an application may dictate (or simply benefit from) a specific surface texture from non-slip to high polish.

- Size: While machining can produce parts in a range of sizes, part size can be limited by the maximum available size of a particular stock material.

- Cost: Cost can be an important factor that will typically fall somewhere after the must-haves and among the nice-to-haves.

Identifying Commonly Used Machining Materials

Over the years, our engineers have identified selected materials that work well for machining processes and that have been popular choices among our customers. For metals, these include aluminum, brass, copper, stainless steel, and steel. Among plastics, designers frequently choose polyether ether ketone (PEEK), ABS, Acetal, nylon, polycarbonate, polyvinyl chloride (PVC), high- and low-density polyethylene, and more. More than 40 different grades of plastic and metal materials are available at FacFox. Some important characteristics of the most popular machining materials include:

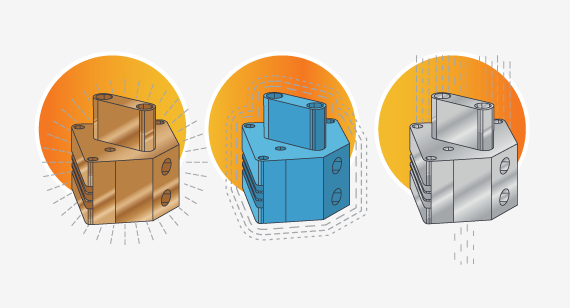

ABS vs. Acetal

- ABS offers high impact strength, low heat conductivity, and low coefficient of friction.

- Acetal offers high mechanical strength, good dimensional stability, and low moisture absorption.

PEEK vs. Ultem

- PEEK offers high abrasion and wear resistance, low moisture absorption, and low coefficient of friction.

- Ultem (PEI) offers extreme strength, and stiffness, and chemical resistance, and high dielectric strength.

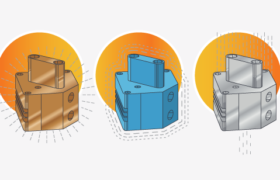

Aluminum 6061 vs 7075

- 6061 offers excellent machinability, low cost, and versatility.

- 7075 offers high strength, hardness, low weight, and heat tolerance.

Finishing Options and Process Selection

Beyond material choices, there are related secondary processes to consider as well. If, for example, the material of choice is one of the available aluminum alloys—6061 and 7075—there are a couple of available and relevant surface treatments to consider. Anodizing would be preferable for durability, while chromate plating is a better choice if the priority is cosmetics.

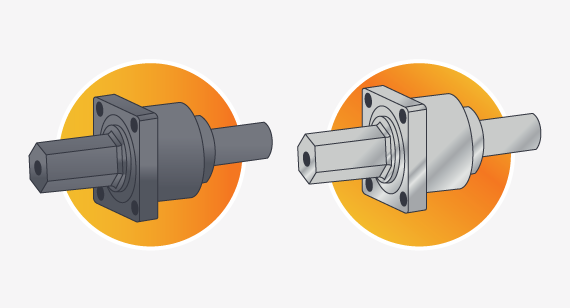

If your design includes threads, you have several options to consider. If the stress and wear on the thread will be minimal, a simple machined-in thread will be sufficient and economical. If stress or wear will be more significant, a replaceable insert—a coil insert or key insert—can extend the life of the part. The key insert will be the choice for the most highly stressed threads.

The final choice to be determined is the actual production process—3-axis machining, 5-axis machining, or turning—which is typically informed by the part design. Having evaluated the part in the initial quoting process, FacFox will recommend the most efficient and economical production method to produce your parts.

Using Machined Prototypes

Machining is often used for end-use production parts, say for a small number of jigs or a low-volume production run of components. But it is often used to produce prototypes that will ultimately be produced in much greater numbers by a process like injection molding. In such cases, you can save money by producing your initial prototypes by machining rather than by molding. When doing so, you’ll want to choose machinable materials that are close, if not identical, to those that will be used in the ultimate production process. If you know what material (or materials) you’ll be considering for your molded parts, your options for the machined prototypes will be similarly limited.

For example, some of the most popular molding resins—ABS and acetal for typical plastic parts or PEEK and Ultem for high-temperature applications—are also available in block form for machining. Using the same resin for machined prototypes as for injection-molded production will give you prototypes that that can be tested and will perform similarly to production parts.

Ultimately, having a range of material choices is preferred, rather than face limitations. As always, for additional help, feel free to contact a FacFox applications engineer at info@facfox.com. To get your next design project started today, simply upload a 3D CAD model for an interactive quote within hours.

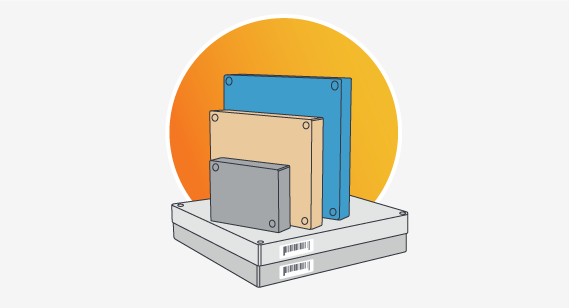

| LOOKING FOR LARGER METAL PARTS? |

|---|

| FacFox offers larger machined part sizes for aluminum 6061 and 7075. The maximum part size is 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.25mm). Increased block size is 24 in. x 16 in. x 4 in. (609mm x 406.4mm x 101.6mm). For many reasons, companies find these large-size options helpful. For example, when designers or engineers need to perform vibration testing, these larger block sizes are preferred options to use. Companies in a number of industries find these larger sizes useful, but especially in the aerospace, defense, and automotive sectors. |