Commodity resins are often inexpensive and easy to process plastics. They are used in all kinds of applications, including toys, packaging, and consumer products.

Engineering resins are plastic materials that have better mechanical and/or thermal properties than commodity plastics. These high-strength plastics are often resistant to high temperatures, wear, and corrosives. They simulate a range of injection-molded plastics to provide engineers with a wide choice of material properties for prototyping, testing, and manufacturing.

All engineering resins require post-curing under UV light to reach their maximum mechanical properties.

Now, read on to find the right type of resin to fit your needs.

The engineering resin materials FacFox offers

| SLA Tough Resin (Lasty-KS) | SLA High-temp Resin -100℃ (YGH-5001) | SLA High-temp Resin – 270℃ (Somos PerFORM) | SLA ABS-like Resin (Lasty-R) | SLA PP-like Resin (Somos EvoLVe 128) | |

|---|---|---|---|---|---|

| Price | $ | $$$ | $$$ | $$ | $$ |

| Max Size | 1700 x 900 x 800 mm (White) 800 x 800 x 500 mm (Grey) |

600 x 600 x 400 mm | 350 x 350 x 300 mm | 800 x 800 x 500 mm | 800 x 800 x 500 mm |

| Min Size | 2 x 2 x 2 mm | 5 x 5 x 5 mm | 5 x 5 x 5 mm | 2 x 2 x 2 mm | 2 x 2 x 2 mm |

| Default Layer Height | 0.1 mm | 0.1 mm | 0.1 mm | 0.1 mm | 0.1 mm |

| Optional Layer Heights | 0.05, 0.1 mm | 0.1 mm | 0.1 mm | 0.05, 0.1 mm | 0.1 mm |

| Tolerance | ±0.2% (±0.2 mm) | ±0.2% (±0.2 mm) | ±0.2% (±0.2 mm) | ±0.2% (±0.2 mm) | ±0.2% (±0.2 mm) |

| Heat endurance | Under 80 ℃ | Under 100 ℃ | Under 268 ℃ | Under 75 ℃ | Under 50 ℃ |

| Smoothness | ★★★★ | ★★★★ | ★★★★ | ★★★★★ | ★★★★ |

| Detail Performance | ★★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★ |

| Accuracy | ★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★ |

| Rigidity | ★★★★ | ★★★ | ★★★ | ★★★ | ★★★★ |

| Flexibility | ★★★★ | ★★ | ★★ | ★★★★ | ★★★★ |

SLA Tough Resin (Lasty-KS)

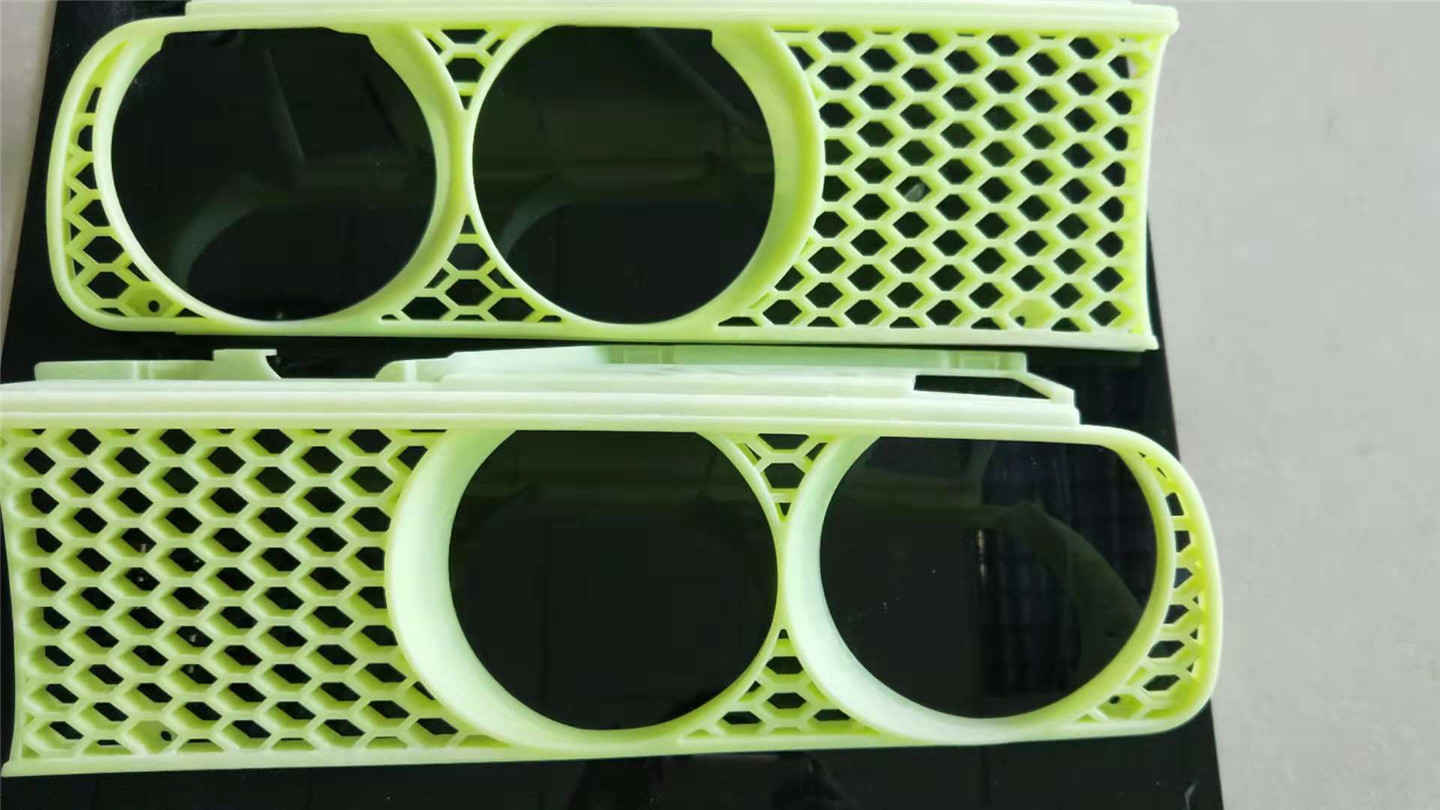

Lasty-KS is a commonly used 3D printing material with great accuracy and durability. Similar to the properties of ABS, it is used with stereolithography (SLA) 3D printers. Lasty-KS can be used in model making and prototyping of automotive, medical, consumer electronics, etc.

The durability of the parts printed with Lasty-KS extends 6.5 months. It’s light green and yellow-toned white at first, then gradually turns into pure white.

Typical Features

- Medium viscosity, easy for coating and cleaning.

- Improved strength retained, improved dimensions retention of parts in humid condition.

- Need minimal part finishing.

- Long shelf life in the machine.

Typical Benefits

- Need less part finishing time, easier post-curing.

- Build accurate and tough parts with improved dimensional stability.

- High-quality control for vacuum casting parts.

- Outstanding machinability.

Physical Properties – Liquid Material

| Appearance | Light yellow and green toned white |

| Density | 1.13 g/cm3 @ 25 ℃ |

| Viscosity | 390 cps @ 26 ℃ |

| Dp | 0.141 mm |

| Ec | 8.6 mJ/cm2 |

| Building layer thickness | 0.1 mm |

Mechanical Properties of 90 Minutes Post-Cured Material

| MEASUREMENT | VALUE |

|---|---|

| Hardness, Shore D | 86 |

| Flexural modulus, Mpa | 2,498-2,550 |

| Flexural strength, Mpa | 70-75 |

| Tensile modulus, MPa | 2,451-2,565 |

| Tensile strength, MPa | 40-56 |

| Elongation at break | 11-17% |

| Poisson’s Ratio | 0.38-0.42 |

| Impact strength notched Izod, J/m | 30 – 43 |

| Heat deflection temperature, ℃ | 63 |

| Glass transition, Tg,℃ | 75 |

| Coefficient of thermal expansion, /℃ | 92*E-6 |

| Density | 1.15 |

| Dielectric Constant 60 Hz | 4.5 |

| Dielectric Constant 1 kHz | 3.9 |

| Dielectric Constant 1 MHz | 3.6 |

| Dielectric Constant 1 MHz | 14.8 |

SLA High-temp Resin – 100℃ (YGH-5001)

YGH-5001 resin is a heat-resistant and high-resolution material that creates detailed parts. YGH-5001 has high heat deflection temperatures compared to common SLA resins. Besides, some people also have a preference for the grey color.

Key Benefits

- Excellent detail resolution

- 30% lower shrinkage rate

- Fast, easy processing & finishing

- Superior high heat tolerance

Applications

- Industrial tooling

- High-temperature testing

- Electrical casings

- Automotive housings

Physical Properties – Liquid Material

| Appearance | Grey |

| Density | 1.1 g/cm3 @ 25 ℃ |

| Viscosity | 580 cps @ 28 ℃ |

| Dp | 0.10 mm |

| Ec | 15.0 mJ/cm2 |

| Building layer thickness | 0.10 mm |

Mechanical Properties of Post-Cured Material

| MEASUREMENT | VALUE |

|---|---|

| Hardness, Shore D | 85 |

| Flexural modulus, Mpa | 2,900-3,220 |

| Flexural strength, Mpa | 64-69 |

| Tensile modulus, MPa | 1,900-2,090 |

| Tensile strength, MPa | 40-44 |

| Elongation at break | 13-20% |

| Impact strength notched Izod, J/m | 34.4 |

| Heat deflection temperature, ℃ | 99.6 |

SLA High-temp Resin – 270℃ (Somos PerFORM)

SLA Somos PerFORM is a ceramic-filled material that creates extremely stiff and detailed parts. PerFORM has one of the highest heat deflection temperatures of all SLA resins, starting at 132°C and reaching up to 268°C with a thermal post-cure.

Try this material for fixtures, structural features, prototype mold inserts, and wind tunnel test models. This material is also available in high resolution.

Key Benefits

- Excellent detail resolution

- Fast, easy processing & finishing

- Superior high heat tolerance

Applications

- Tooling

- Wind tunnel testing

- Hot air, gas, and fluid flow

- Electrical casings

- Automotive housings

Physical Properties – Liquid Material

| Appearance | Off white |

| Density | ~1.61 g/cm3 @ 25°C |

| Viscosity | ~1,000 cps @ 30°C |

| Dp | 4.3 mils |

| Ec | 7.8 mJ/cm² |

| E10 | 80 mJ/cm² |

Mechanical Properties of Post-Cured Material

| MEASUREMENT | UV Post-cure / Thermal Post-cure |

|---|---|

| Tensile Strength | 68 MPa / 80 MPa |

| Tensile Modulus | 10,500 MPa / 9,800 MPa |

| Elongation at Break | 1.1% / 1.2% |

| Poisson’s Ratio | 0.32 / 0.33 |

| Flexural Strength | 120 MPa / 146 MPa |

| Flexural Modulus | 10,000 MPa / 9,030MPa |

| Izod Impact (Notched) | 17 J/m / 20 J/m |

| Hardness (Shore D) | 94 / 93 |

| Water Absorption | 0.2% / 0.1% |

SLA ABS-like Resin (Lasty-R)

Lasty-KS is a commonly used 3D printing material with great accuracy and durability. Similar to the properties of ABS, it is used with stereolithography (SLA) 3D printers. Lasty-KS can be used in model making and prototyping of automotive, medical, consumer electronics, etc.

The durability of the parts printed with Lasty-KS extends 6.5 months. It’s light green and yellow-toned white at first, then gradually turns into pure white.

Typical Features

- Medium viscosity, easy for coating and cleaning.

- Improved strength and stability in humid conditions.

- Need minimal part finishing.

- Long lifetime in the machine.

- Low bottom contraction.

Typical Benefits

- Less finishing, easier post-curing.

- Rather high toughness.

- High-quality control for vacuum casting parts.

- Low shrinkage and good resistance to yellowing.

- Build accurate and tough parts with improved dimensional stability.

- Outstanding machinability.

Physical Properties – Liquid Material

| Appearance | Yellow |

| Density | 1.11-1.15 g/cm3 @ 25 ℃ |

| Viscosity | 395-480 cps @ 31 ℃ |

| Dp | 0.13-0.145 mm |

| Ec | 9.5-10.5 mJ/cm2 |

| Building layer thickness | 0.05-0.12 mm |

Mechanical Properties of 90 Minutes Post-Cured Material

| MEASUREMENT | VALUE |

|---|---|

| Hardness, Shore D | 75-84 |

| Flexural modulus, Mpa | 2,592-2,671 |

| Flexural strength, Mpa | 63-68 |

| Tensile modulus, MPa | 2,489-2,591 |

| Tensile strength, MPa | 36-52 |

| Elongation at break | 17-28% |

| Poisson’s Ratio | 0.4-0.44 |

| Impact strength notched Izod, J/m | 50-75 |

| Heat deflection temperature, ℃ | 47-58 |

| Glass transition, Tg,℃ | 50-62 |

| Coefficient of thermal expansion, /℃ | 90-102*E-6 |

| Density | 1.12-1.18 |

| Dielectric Constant 60 Hz | 4.2-5.0 |

| Dielectric Constant 1 kHz | 3.3-4.2 |

| Dielectric Constant 1 MHz | 3.2-4.0 |

| Dielectric Constant 1 MHz | 12.8-16.1 |

SLA PP-like Resin (Somos EvoLVe 128)

Somos® EvoLVe 128 is a durable stereolithography material that produces accurate, high-detailed parts and has been designed for easy finishing. It has a look and feel that is almost indistinguishable from finished traditional thermoplastics, making it perfect for building end-use parts like jigs & fixtures, or prototypes for functional testing applications – resulting in time, money and material savings during production or product development.

Product Features

- Easy to clean & finish

- High strength & durability

- Accurate & dimensionally stable

- High detail

Applications

- Aerospace, automotive, medical, electronic applications

- Consumer products

- Tough, functional prototypes

- Snap-fit designs

- Jigs & fixtures

Physical Properties – Liquid Material

| Appearance | White |

| Density | ~1.12 g/cm3 @ 25°C |

| Viscosity | ~380 cps @ 30°C |

| Dp | 4.3 mils |

| Ec | 9.3 mJ/cm² |

| E10 | 95.1 mJ/cm² |

Mechanical Properties of Post-Cured Material

| MEASUREMENT | UV Post-cure |

|---|---|

| Tensile Strength at Break | 56.8 MPa |

| Tensile Modulus | 2,964 MPa |

| Elongation at Break | 11% |

| Flexural Modulus | 2,654 MPa |

| Izod Impact (Notched) | 38.9 J/m |

| Hardness (Shore D) | 82 |

| Water Absorption | 0.40% |