Binder jetting metal 3D printing is a fast and cost-effective way of making metal parts with complex shapes and high detail. It uses a liquid binder to join layers of metal powder, and then sintering or infiltration to make the parts solid and strong.

In this post, we will explain what binder jetting metal 3D printing is, how it works, and why you should try it. We will also cover the benefits and challenges of this technology, and give you some design tips to make the most of it. If you are interested in binder jetting metal 3D printing, read on to learn more!

Q: What is metal binder jetting 3D printing technology?

A: Binder jetting metal 3D printing is a way of making metal parts by spraying a glue-like liquid on layers of metal powder. The glue sticks the powder together to form the shape of the part.

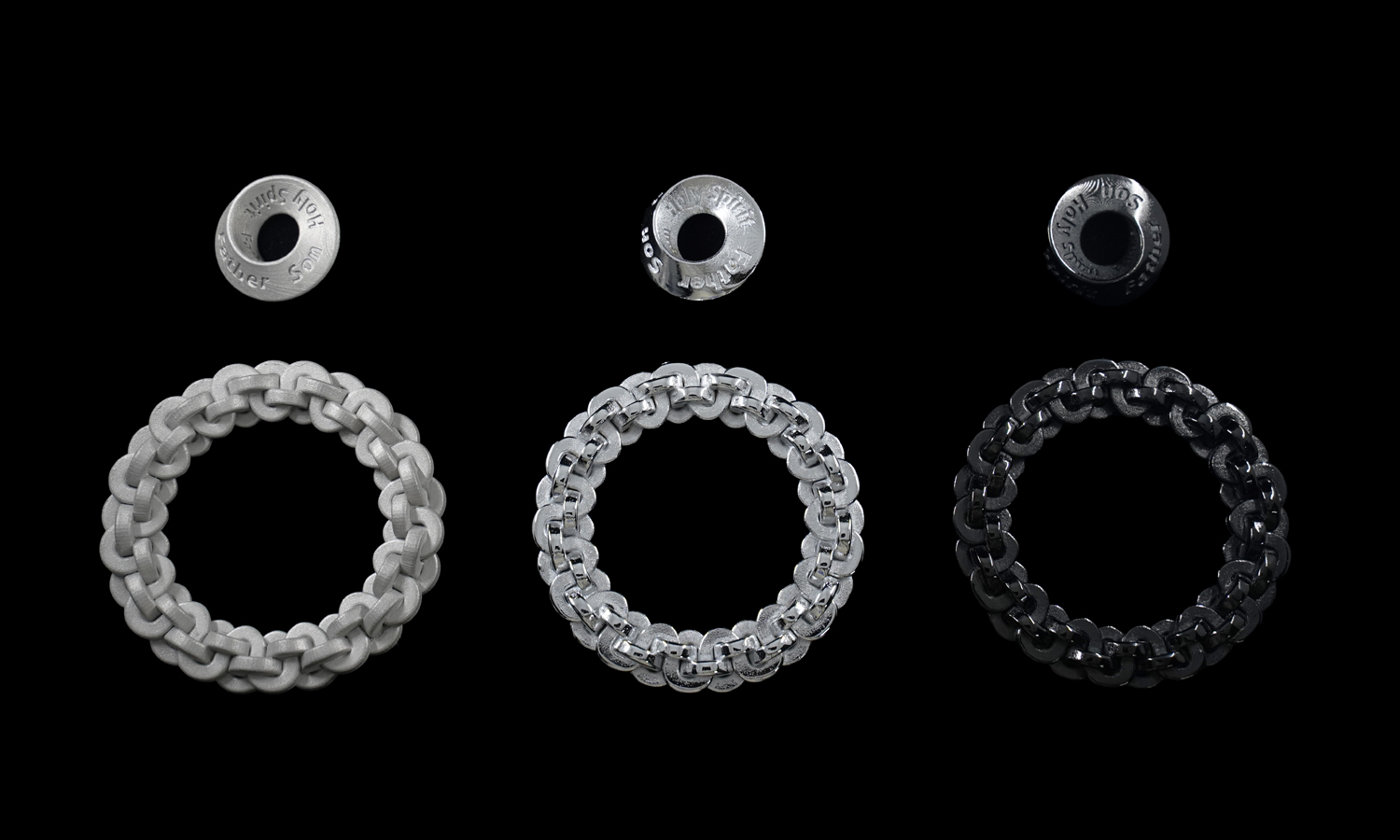

Then the green part is heated or filled with another metal to make it solid and strong. It requires extra processes like CNC machining and electroplating to achieve a smooth surface.

Q: What are the benefits of metal binder jetting?

A: Binder jetting metal 3D printing has some cool benefits, such as:

- It can make complex shapes without needing any extra support, because the loose powder holds the part in place.

- It can make parts with nice detail and accuracy, because the glue drops and powder grains are very small.

- It can make parts with fast speed and low cost, because it doesn’t use high temperatures or lasers.

Q: What are the challenges of this technology?

A: Binder jetting metal 3D printing faces some challenges, such as:

- It has a high shrinkage rate of about 20% when heated, which can affect the size and shape of the parts. It’s preferred when you don’t mind a lot about the exact dimension of the prints.

- It is not good for hollow parts with fine details, as the loose powder may not be removed completely from the inside. This way we don’t recommend this technology to jewelry designers.

- It is not economical for manufacturing a single part, as the process is more cost-effective for small-batch production.

- It is also not good for very large parts, as the printer size may not be enough and the deformation risk may be high.

Q: What are the design rules for metal binder jetting parts?

A: To design parts for metal binder jetting, you should follow some tips, such as:

- Use a minimum wall thickness of 2 mm to avoid damage during handling and post-processing.

- Use a minimum feature size of 2 mm to avoid breaking in the green state.

- Use a minimum hole diameter of 1.5 mm and a minimum escape hole diameter of 5 mm for hollow parts.

- Use fillets with a minimum radius of 1 mm on all possible edges to avoid cracking in the green state.

- Use supports or braces for thin or unsupported features and remove them after sintering or infiltration.

- Consider the shrinkage rate of 18% to 21% during sintering or infiltration and adjust the part dimensions accordingly.

- Avoid large flat surfaces or sharp corners that may warp or curl during sintering or infiltration.

Q: What metal materials could be used for binder jetting?

A: Some materials that could be used for metal binder jetting are:

- Stainless steel: a corrosion-resistant metal that is widely used for various applications, such as medical devices, automotive parts, and aerospace components.

- Inconel: a nickel-based superalloy that has high strength and temperature resistance, suitable for extreme environments, such as jet engines, gas turbines, and nuclear reactors.

- Copper: a ductile and conductive metal that has good thermal and electrical properties, ideal for heat sinks, electrical contacts, and coils.

- Titanium: a lightweight and biocompatible metal that has high strength and corrosion resistance, perfect for implants, prosthetics, and aerospace parts.

- Tungsten carbide: a hard and wear-resistant metal that has high stiffness and density, excellent for cutting tools, wear parts, and armor-piercing rounds.

Q: Why should I choose FacFox’s 3D printing services?

A: FacFox is a great choice for binder jetting printing services, offering:

- High-quality parts with excellent properties and finish.

- Competitive prices and fast delivery times for your orders.

- Professional customer service and technical support for your projects.

We mainly focus on stainless steel and titanium alloy recently, and will publish more materials with metal binder jetting.

If you are interested in binder jetting metal 3D printing, contact FacFox today and get a quote for your order! You can either send your files to info@facfox.com, or get an instant quote on Insta3DP.