By supporting the arch of the foot and balancing the stress of the sole, orthotic insole can play a good role in correcting the foot structure, helping the foot to stabilize or maintain in a good posture, improving the function of the foot, reducing the compression of blood vessels and nerves and relieving pain. As a conservative treatment, allowing some patients to get rid of surgery while relieving pain is increasingly accepted by the public.

However, foot arch height is unique to each of us and ranges from flat as a board to sky-high. When people with flat feet think about what type of insoles to buy, things can get really confusing. Due to the difference in the foot shape and arch of each person, the design of the orthotic insole needs to be personalized according to the patient’s situation.

How to make a 3D printed orthotic insole

The traditional orthotic insole is molded out of plaster/foam box, polished and adjusted manually, or made by CNC machining. The process is always accompanied by a polluted working environment and poor patient’s medical experience.

The patients need to pick from many types of traditional orthotic insoles, but 3D printed insoles are totally different: they are customized for each patient. A 3D scanner collects all the necessary information from the patient, then the computer will analyses the stress on your feet and design the perfect shape for you, and the doctors can select the most appropriate material to buffer the shock.

Here are the recommended materials for making shoe insoles:

- DLP Flexible Resin

The material is suitable for prototyping parts normally produced with silicone like shoe sole and connectors. DLP resin is ideal for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. - SLS TPU Rubber

As a strong, wear-resistant and elastic substance, SLS TPU is a natural choice for tailor-made shoes and clothes, complex tube geometries or orthopedic parts.

3D printed orthotic insole production process

In the 3D printing reception center of the hospital, professor Wang Jinwu’s team provides professional 3D printing orthotic insole medical services. Every pair of orthotic insole needs to undergo optical scanning, plantar pressure analysis, computer software design, insole production, adaptation, and other processes.

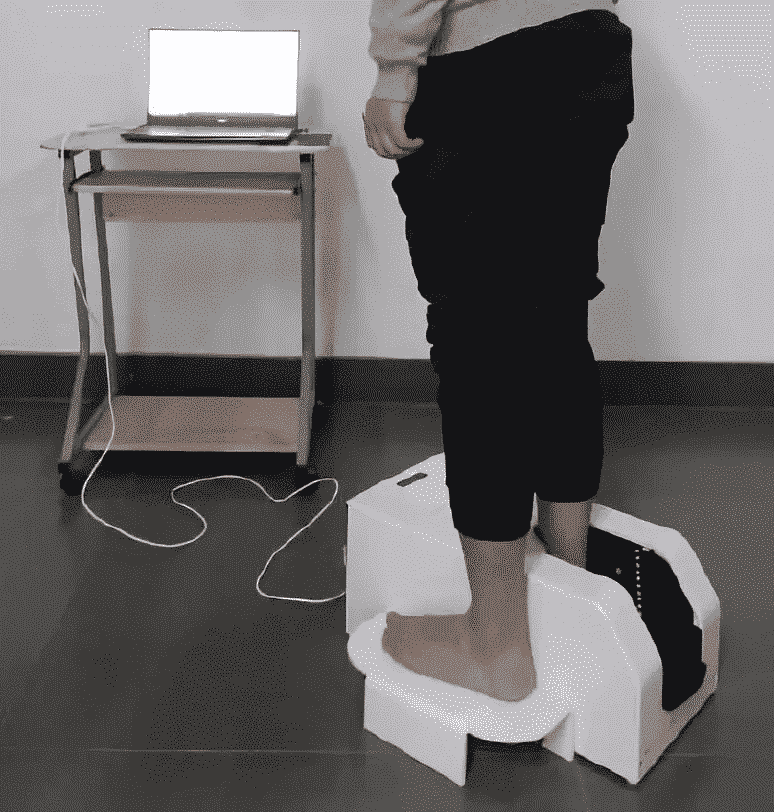

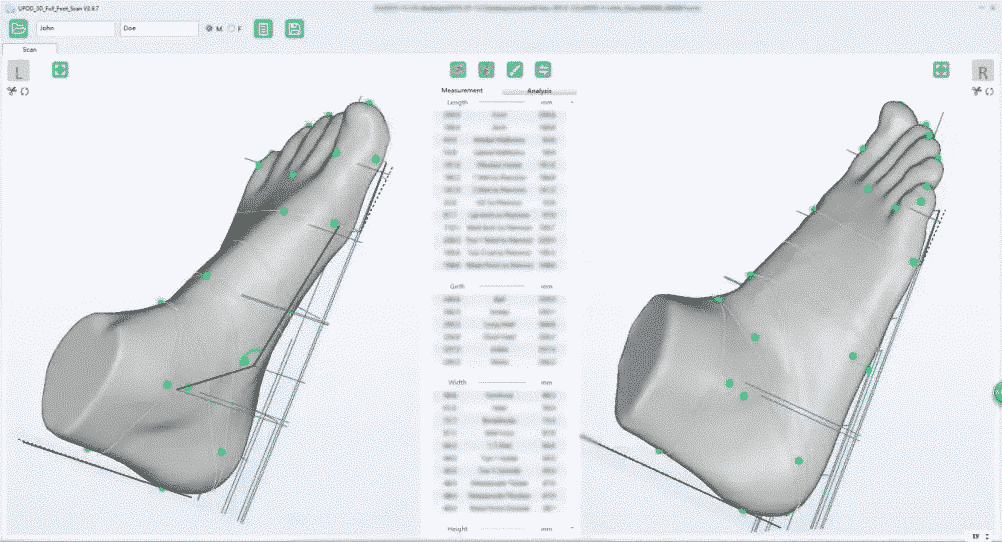

- The 3D foot scanner can quickly obtain digital models of the foot and ankle

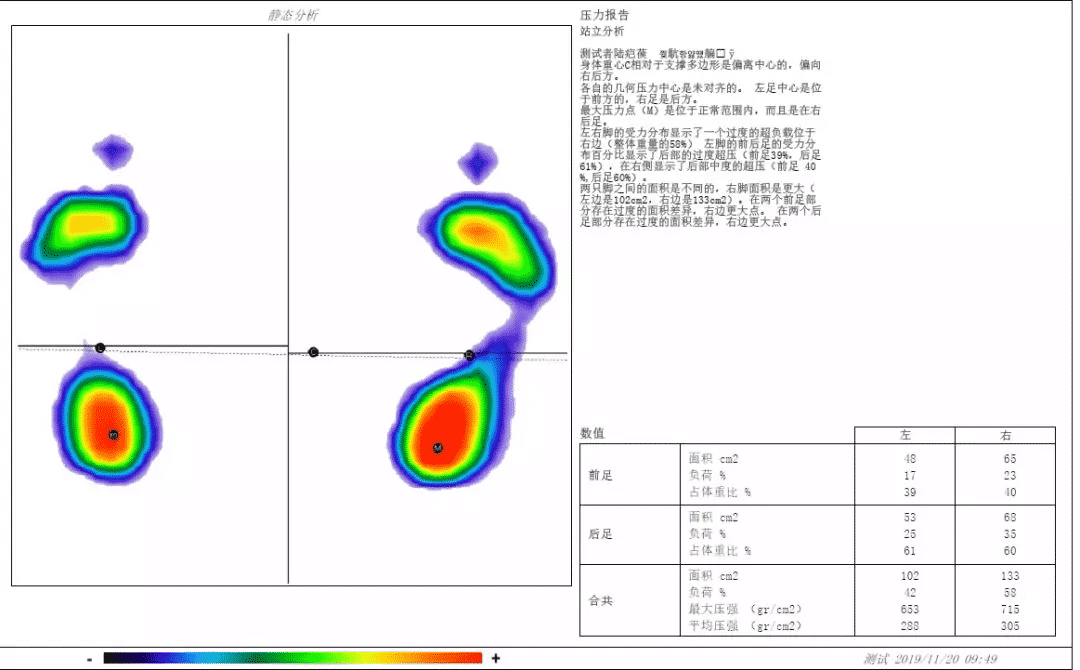

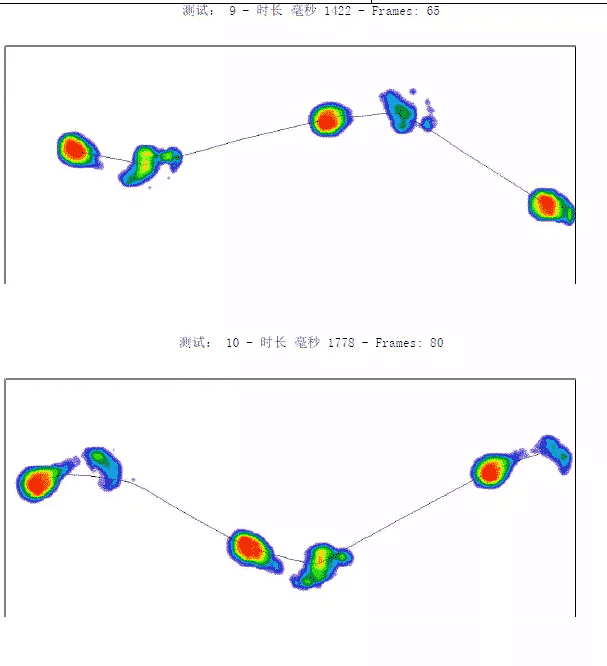

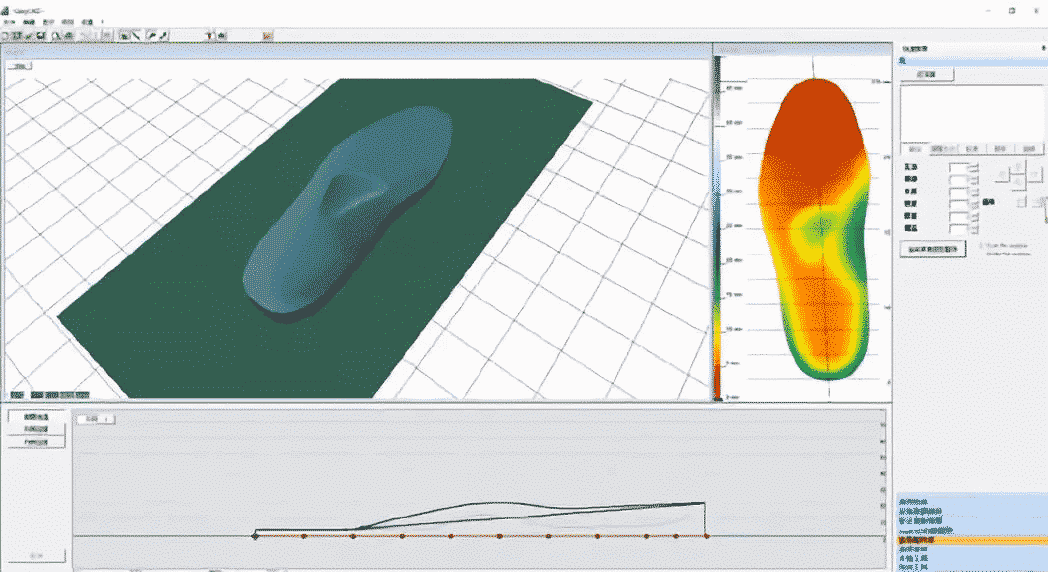

- Dynamic and static plantar pressure is obtained by foot pressure acquisition and analysis system

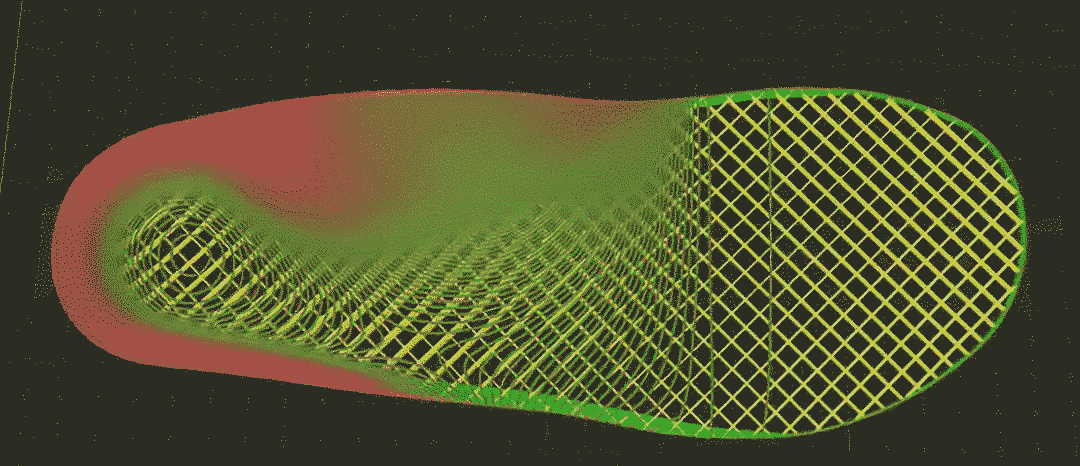

- Computer-aided orthotic insole design

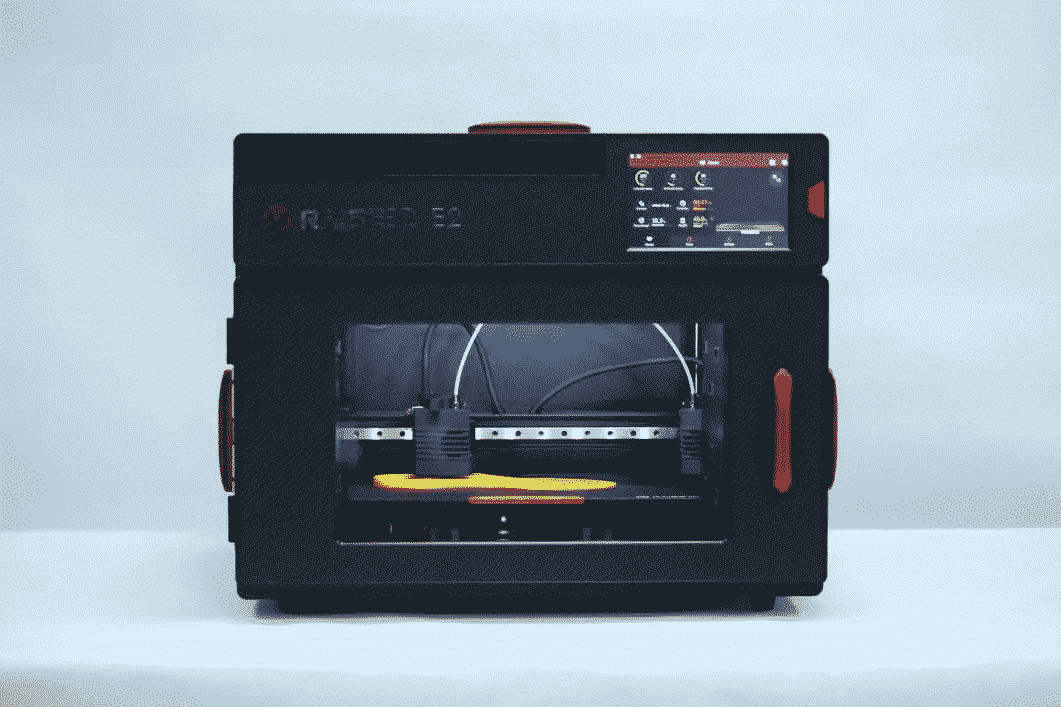

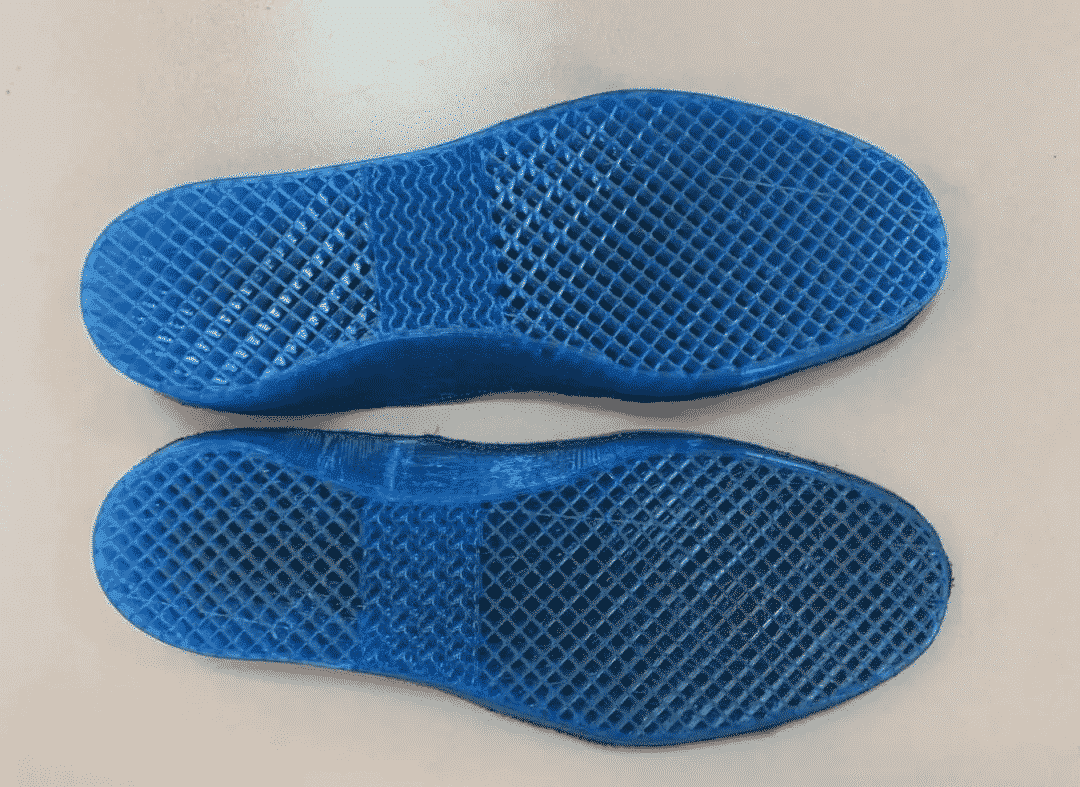

- 3D printing technology to make orthotic insoles

- Patient with the customized orthotic insole