Transparency is sought after for many applications and in a wide range of industries: from the production of lenses for optical engineering or medical purposes to the manufacturing of aesthetically pleasing casings for products. In this article, we will cover all the materials FacFox offers for transparent 3D prints.

| SLA Clear Resin | SLA Frosted Clear Resin | SLA Bio-Clear Resin | MJP Bio-Clear Resin | PolyJet Clear Resin | PolyJet Bio-Clear Resin | |

|---|---|---|---|---|---|---|

| Max. Bed

Size (mm) |

600 x 600 x 450 | 600 x 600 x 450 | 380 x 380 x 250 | 298 x 185 x 203 | 1000 x 800 x 500 | 1000 x 800 x 500 |

| Min.Bed

Size (mm) |

5 x 5 x 5 | 5 x 5 x 5 | 2 x 2 x 2 | 2 x 2 x 2 | 2 x 2 x 2 | 2 x 2 x 2 |

| Layer Height

(mm) |

0.1 | 0.1 | 0.075 | 0.025 | 0.016 | 0.016 |

| Tolerance | max(±0.3%, ±0.3 mm) | max(±0.2%, ±0.2 mm) | max(±0.2%, ±0.2 mm) | max(±0.2%, ±0.2 mm) | max(±0.2%, ±0.2 mm) | max(±0.2%, ±0.2 mm) |

| Heat endurance | Under 50℃ | Under 48℃ | Under 50℃ | Under 56℃ | Under 45℃ | Under 45℃ |

| Smoothness | ★★★★★ | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★★ |

| Detail | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Rigidity | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ |

| Flexibility | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ |

| Biocompatible | No | No | Yes | Yes | No | Yes |

| Food Safe | No | No | No | No | No | No |

| Price | $$$ | $$ | $$$$ | $$$$ | $$$$ | $$$$ |

SLA Clear Resin

- Somos WaterClear Ultra 10122

Somos WaterClear Ultra 10122 is an optically clear and colorless resin that is easy to use and fast to build. It produces functional and accurate parts that simulate an acrylic appearance.

WaterClear Ultra 10122 also has excellent temperature resistance and tensile strength for master patterns and rigid parts for optical light transmission testing. This material also provides refractive values similar to engineered plastics for functional testing in optical light transmission work.

- Somos WaterShed XC 11122

Somos WaterShed XC 11122 produces transparent yellow/green parts with a smooth finish. It provides exceptional clarity, has low viscosity and is water-resistant, perfect for fluid-flow analysis.

As one of the industry’s most popular SL materials, Somos® WaterShed XC 11122 is the clear solution for numerous applications., Somos® WaterShed mimics the look and feel of clear thermoplastics, such as acrylic. This versatility means Somos® WaterShed is the ideal material in markets such as automotive, aerospace and consumer electronics.

Applications:

- General purpose prototyping

- Models requiring high clarity

- Headlamps and lenses

- Fluid flow and visualization models

- Transparent assemblies

- Snapfits and complex assemblies

SLA Frosted Clear Resin (3D Systems M3-X)

This translucent plastic delivers ABS-like performance and feel with high temperature resistance and toughness for rigorous applications.

Applications:

- Functional prototypes and end products

- Low-cost prototype

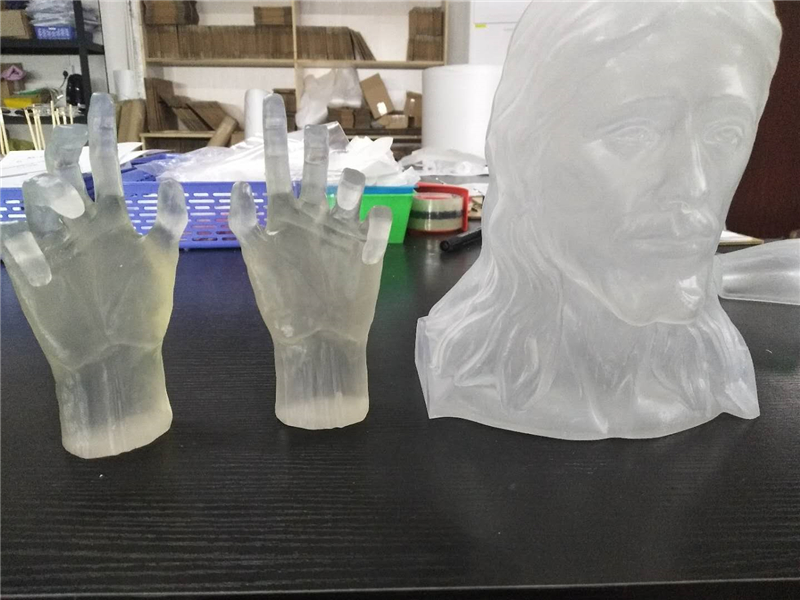

SLA Bio-Clear Resin (3D Systems Accura ClearVue)

![]()

It is a high clarity plastic with excellent humidity/moisture resistance and simulates the properties and appearance of Polycarbonate and ABS. It’s suitable for a multitude of applications where transparency is a key, such as headlamps, complex assemblies or fluid flow. It’s capable of meeting USP Class VI.

Applications:

- General purpose prototyping

- Models requiring high clarity

- Headlamps and lenses

- Fluid flow and visualization models

- Transparent assemblies

- Snapfits and complex assemblies

- Medical models and medical devices

MJP Bio-Clear Resin (3D Systems M3 Crystal)

With high durability and stability, it’s ideal for see-through functional testing and rapid tooling applications. This material is also USP Class VI capable for approved medical applications.

Applications:

- Surgical guides

- Medical models and devices

- Dental models and implants

- Applications requiring prolonged skin contact

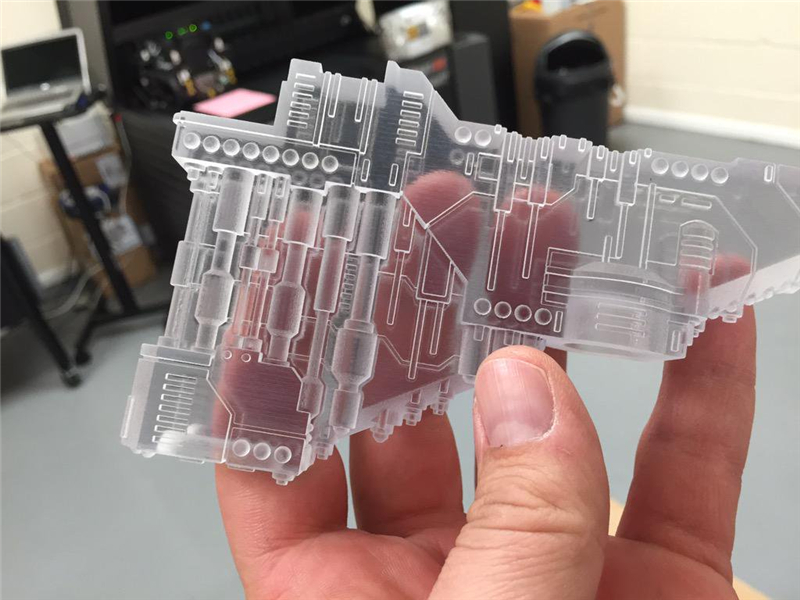

PolyJet Clear Resin (Stratasys VeroClear)

VeroClear is a transparent material that simulates PMMA (polymethyl methacrylate), commonly known as acrylic.

It offers strength, stiffness, elongation and impact resistance, and the ability to blend with other materials for a range of opacities, hues and hardnesses. VeroClear enables visualization of internal components and features, and simulation of glass ideal for form and fit testing of see-through parts. For best clarity, polish, lacquer or photo bleach parts.

Like PMMA, VeroClear is used as an alternative to glass and is ideal for concept modeling and design verification of clear parts. Ideal for presentation models, small components with complex features and anatomical models, Vero produces parts with fine feature detail and smooth surface finish. Vero can be built in a near-endless CMYKW color range and transparencies. Companies can reduce time to market by enabling designers to integrate product images in marketing materials and ensure that packaging and displays work seamlessly with end products.

Applications:

- Eyewear and lens

- Light covers

- Medical models and devices

- General purpose prototyping

- Transparent assemblies

- Snapfits and complex assemblies

PolyJet Bio-Clear Resin (Stratasys Biocompatible MED610)

MED610 is a transparent, biocompatible PolyJet™ material medically approved for bodily contact. The material is designed for both medical and dental applications and is approved for permanent skin contact (more than 30 days) and limited mucosal membrane contact (up to 24 hours).

Stratasys engaged a third-party laboratory that conducted a MED610 material evaluation and found minimal biocompatibility risk in use for gas pathway components in respiratory and ventilator equipment. The evaluation was performed by experts in the field who based their conclusion on a set of biocompatibility tests for which the material was already approved and assessed the residual risk to meet ISO 18562-1.

Applications:

- Surgical guides

- Medical models and devices

- Dental aligners and implants

- Applications requiring prolonged skin contact