Many factors come into play when comparing the material properties of thermoplastics found in injection molding versus “thermoplastic-like” materials used in an industrial-grade 3D printing technology like stereolithography (SLA).

SLA is a plastic 3D printing process that uses a thermoset liquid, not a thermoplastic, which is UV-cured in layers to form final parts. Because of this major difference in fabrication methods, material properties like tensile strength, heat deflection, and flexural modulus may differ from SLA’s more traditional counterpart. Furthermore, SLA produces anisotropic properties where the values for X, Y, and Z axes may differ depending on the orientation of the build—a consideration unique to 3D printing processes.

At FacFox, a thorough selection of thermoplastic-like materials is offered through SLA, but what may surprise you is the versatility and range of potential applications for SLA parts. In the tables and charts below, we’ll take you through each material and its properties, and compare them with one another (as well as with molded plastics) to help you decide how to best implement SLA.

Polycarbonate-Like Materials

PC-Like Advanced High Temp (Accura 5530) material is best used for parts that need strength and stiffness combined with high temperature resistance, such as under-the-hood automotive or electrical components. With a thermal post-cure, the part’s heat deflection can be improved even further, but at the expense of durability. Note that a thermal post-cure will transition the part color to a slightly amber hue.

PC-Like Translucent/Clear (Accura 60) offers the ability for fine detail while providing good stiffness in parts. Common applications include durable prototypes for automotive, consumer electronics, and lighting components, as well as medical instruments. PC-Like Translucent/Clear (Accura 60) has a high tensile strength and modulus, making it ideal for prototyping parts similar to molded polycarbonate. PC-Like Translucent is an ideal material for polycarbonate-like parts when high temperature resistance is not required. Note that custom finishing is required to achieve functional clarity of parts built with PC-Like Translucent/Clear.

| TEST METHOD | PC-LIKE ADVANCED HIGH TEMP (ACCURA 5530) |

PC-LIKE TRANSLUCENT/CLEAR (ACCURA 60) |

PC LEXAN 940 (MOLDED) |

|

|---|---|---|---|---|

| Water Absorption | ASTM D570 | 0.55 ± 0.15%

(20 degrees C, 50% relative humidity) |

— | 24 hr.: 0.15% Equilibrium, 73 degrees F (23 C): 0.35% Equilibrium 212 degrees F (100 C): 0.58% |

| E-modulus (x-y plane) |

ASTM D638* | 3,400 ± 400 MPa | 3,500 ± 400 MPa | — |

| Tensile Strength (x-y plane) |

ASTM D638* | 50 ± 10 MPa | 75 ± 10 MPa | Yield: 8,990 psi/62.0 MPa Break: 7,980 psi/55.0 MPa |

| Elongation at Break (x-y plane) |

ASTM D638* | 3 ± 2% | 7 ± 4% | 90% |

Chart 1: Two PC-like materials and one molded PC thermoplastic are compared across four material property categories.

*test speed 10mm/min.

ABS-Like Materials

ABS-Like Black (Renshape SL7820) has high strength and good dimensional stability, even in high humidity. The material is black and commonly used in automotive parts, consumer packaging, electrical housings, and toys due to its impact resistance and ease of secondary finishing that provides the appearance of production quality.

MicroFine™ is an exclusive FacFox material that can build ultra-fine features in micro resolution. MicroFine™ is available in a green or gray color. Layer thicknesses of 0.001 in. and feature sizes of 0.0025 in. are possible with MicroFine™ to accommodate applications that require parts that are generally less than a cubic inch in size.

ABS-Like Translucent/Clear (Somos Watershed XC 11122) is a strong, durable, low moisture absorption ABS-like material. It’s nearly colorless and mimics a clear engineering-grade plastic. Watershed’s high clarity makes it a perfect material for prototyping lenses, flow-visualization models and microfluidics. Note that secondary operations will be required to get the material functionally clear. Watershed will also retain a very light blue hue afterward.

ABS-Like White (Accura Xtreme White 200) offers strength and durability, lending itself well to applications that require flexible snap-fit features. Note that ABS-Like White (Accura Xtreme White 200) has the lowest heat deflection of the SLA materials offered at FacFox.

| TEST METHOD | ABS-LIKE BLACK (RENSHAPE SL 7820) |

MICROFINE™ | ABS-LIKE TRANSLUCENT/CLEAR (WATERSHED XC 11122) |

ABS-LIKE WHITE (ACCURA XTREME WHITE 200) | ABS BAYBLEND FR 110 (MOLDED) |

|

|---|---|---|---|---|---|---|

| Water Absorption | ASTM D570 | 0.25 ± 0.15% | 0.85% ± 0.15% | 0.35 ± 0.15% | 0.65 ± 0.15% | 0.050% (73.4 degrees F, 23 C) |

| E-modulus (x-y plane) |

ASTM D638* | 3,000 ± 400 MPa | — | 2,900 ± 400 MPa | 3,300 ± 400 MPa | — |

| Tensile Strength (x-y plane) |

ASTM D638* | 55 ± 10 MPa | 60 ± 10 MPa | 55 ± 10 MPa | 55 ± 10 MPa | Yield: 60 MPa Break: 49.6 MPa |

| Elongation at Break (x-y plane) |

ASTM D638* | 5 ± 3% | 8 ± 4% | 6 ± 3% | 9 ± 5% | >50% |

Chart 2: Four ABS-like materials and one molded ABS thermoplastic are compared across four material property categories.

*test speed 10mm/min.

Polypropylene-Like Material

PP-Like Translucent White (Somos 9120) is translucent in appearance, providing excellent resolution and fine detail. You may want to consider Somos 9120 for parts with thin walls or small holes. The PC-like material is also the most flexible SLA material at FacFox, while maintaining its durability. Potential applications include automotive components, electrical housings and medical devices.

| TEST METHOD | PP-LIKE TRANSLUCENT WHITE (SOMOS 9120) | PP POLYPROPYLENE HOMOPOLYMER (MOLDED) | |

|---|---|---|---|

| Water Absorption | ASTM D570 | — | 0.8% |

| E-modulus (x-y plane) |

ASTM D638* | 1,600 ± 300 MPa | — |

| Tensile Strength (x-y plane) |

ASTM D638*. | 35 ± 5 MPa | 5,150 psi/35.5 MPa |

| Elongation at Break (x-y plane) |

ASTM D638* | 25 ± 5% | 400% |

Chart 3: One PP-like material and one molded PP thermoplastic are compared across four material property categories.

*test speed 10mm/min.

Metal Plating

Metal plating is a secondary process that adds a thin copper-nickel coating that provides the look, feel, and strength of a metal part without any added weight. Metal plating adds strength, durability, stiffness, wear resistance, and temperature resistance to SLA parts that previously was not achievable. Note that we typically layer either 0.002 in. or 0.004 in. of plating thickness on parts.

Aesthetically, finished parts look quite similar to aluminum parts. For more detailed information on surface finishes, you can download our free 3D Printing Finish Guide.

| TEST METHOD | METAL PLATING | |||

|---|---|---|---|---|

| 10% METAL VOLUME | 20% METAL VOLUME | 30% METAL VOLUME | ||

| Tensile Strength | ASTM D638M | 100 (14.5) | 145 (21) | 200 (29) |

| Elongation at Break | ASTM D638M | 0.9% | 1.04% | 1% |

| Mod. Of Elasticity | ASTM D638M | 21,000 MPa | 31,000 MPa | 42,000 MPa |

Chart 4: Three grades of copper-nickel metal plating compared across three material property categories.

Comparison Charts for Material Properties

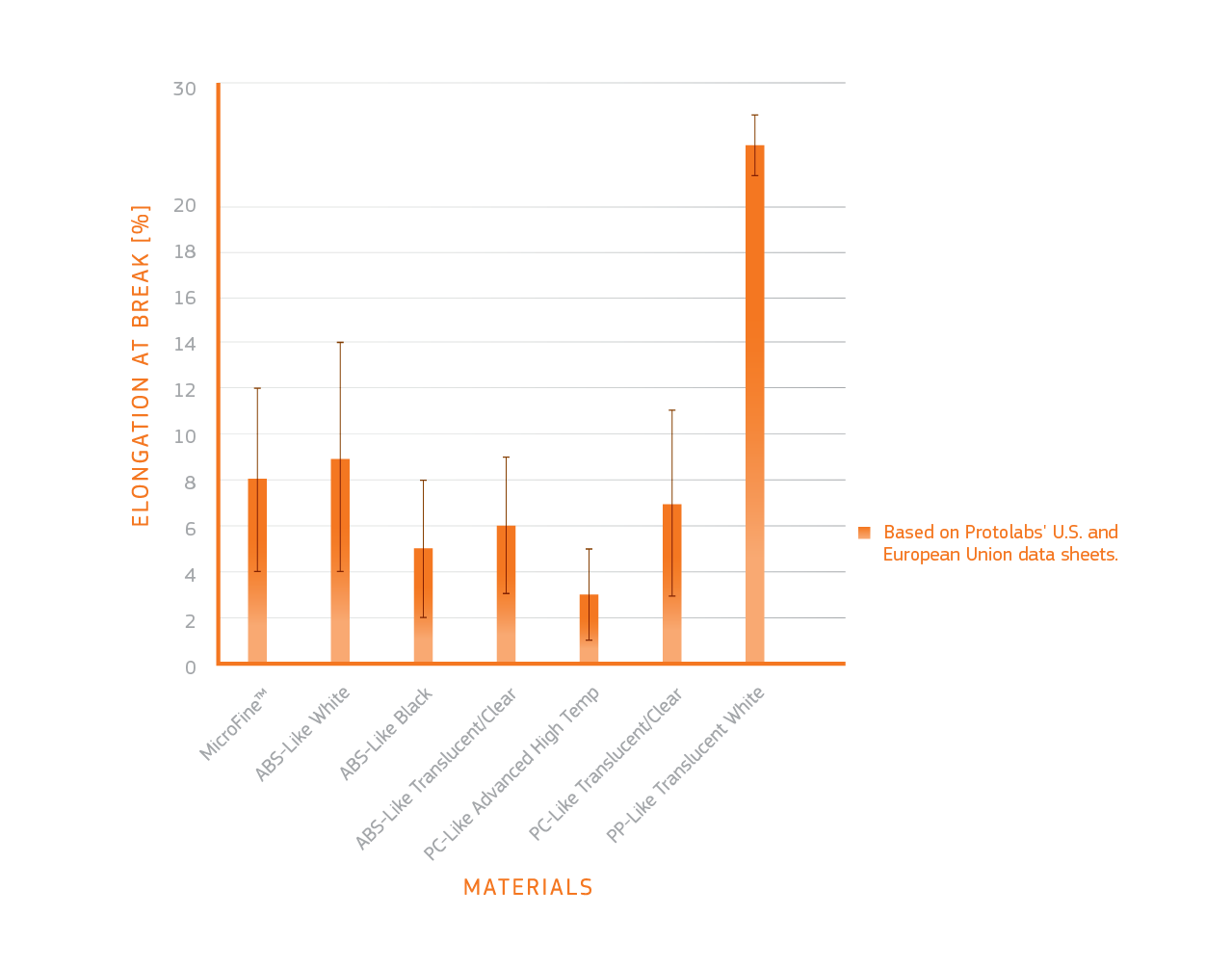

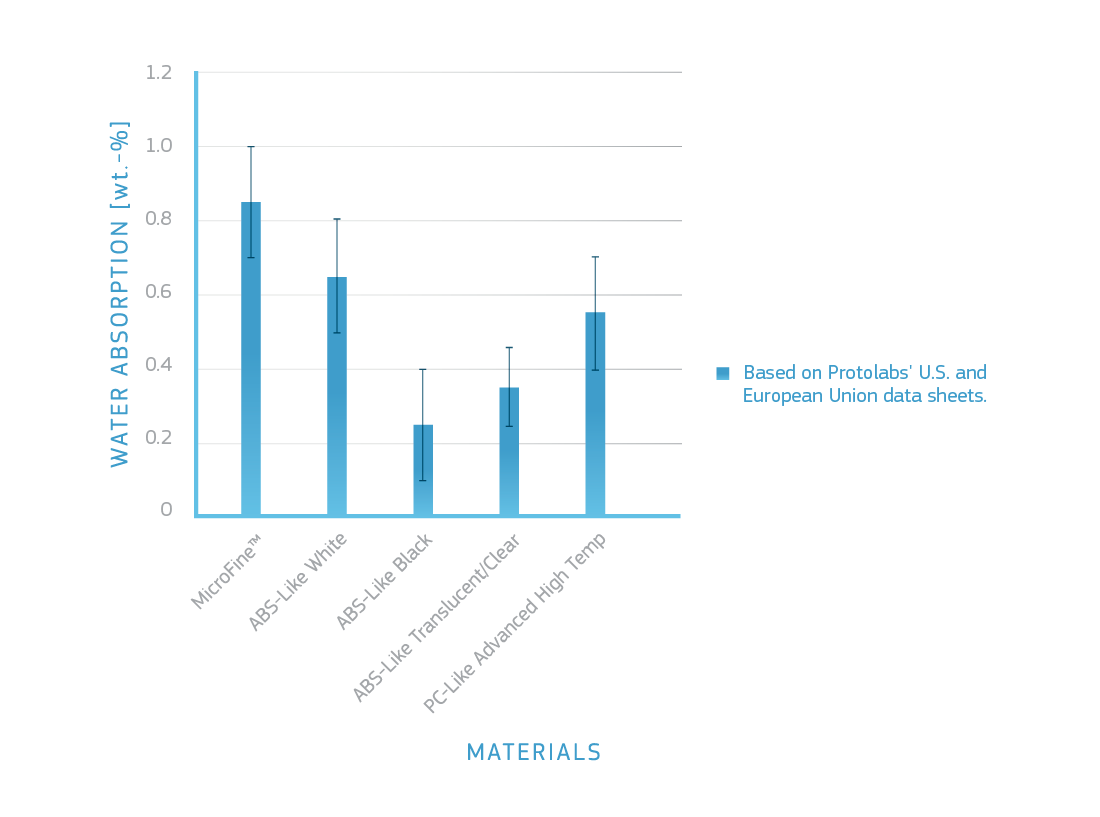

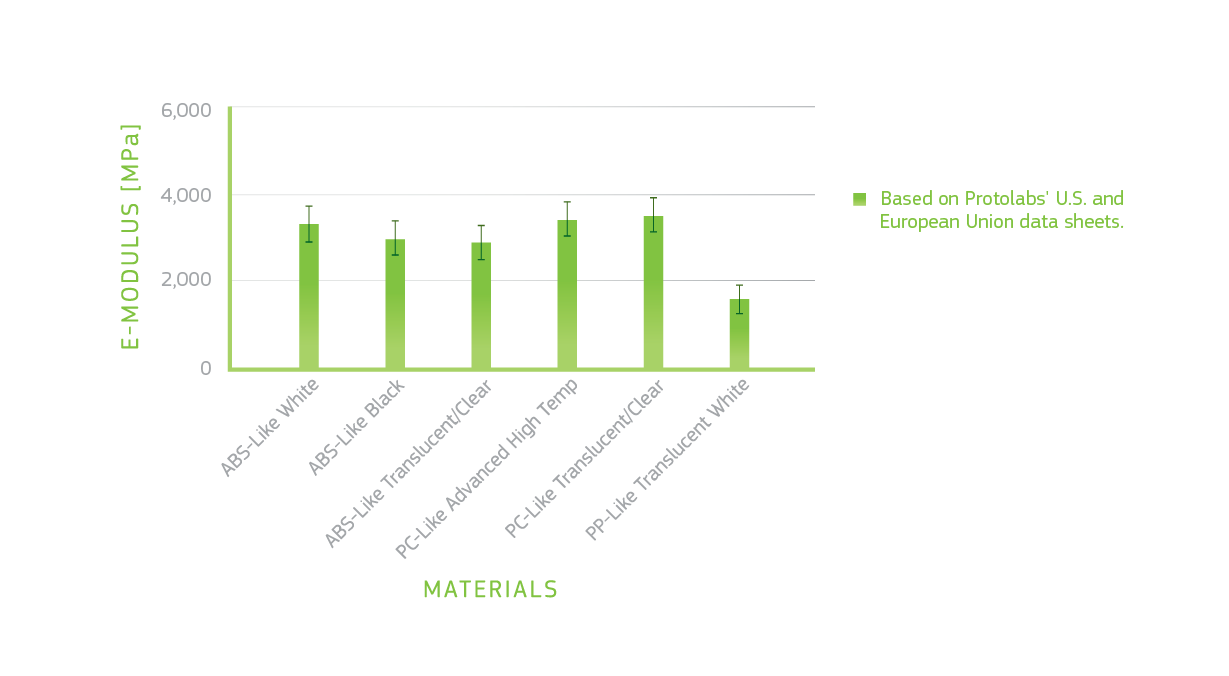

The charts below measure several thermoplastic-like materials suitable for SLA printing against various material properties: Tensile strength, elongation at break, water absorption, and e-modulus.

Tensile Strength

Elongation at Break

Water Absorption

E-Modulus

Parting Notes

Unlike thermoplastics, long-term exposure to UV light and moisture will alter the appearance and mechanical properties of SLA materials if they are not protected by plating or painting. Over time, you may experience part warpage, yellowing, and brittleness in some parts. SLA parts are not intended for long-term use in many instances, but understanding the short-term benefits of having highly detailed form and fit parts to use during early prototyping can be useful.

Remember to work closely with the 3D printing experts to help you select the right material for your project and ensure that build orientation is optimized for your part applications.

Dive deeper into stereolithography at facfox.com. For questions on 3D printing or any of our services, please contact an applications engineer at info@facfox.com.

Have a design ready for 3D printing? Upload it now for an instant quote.