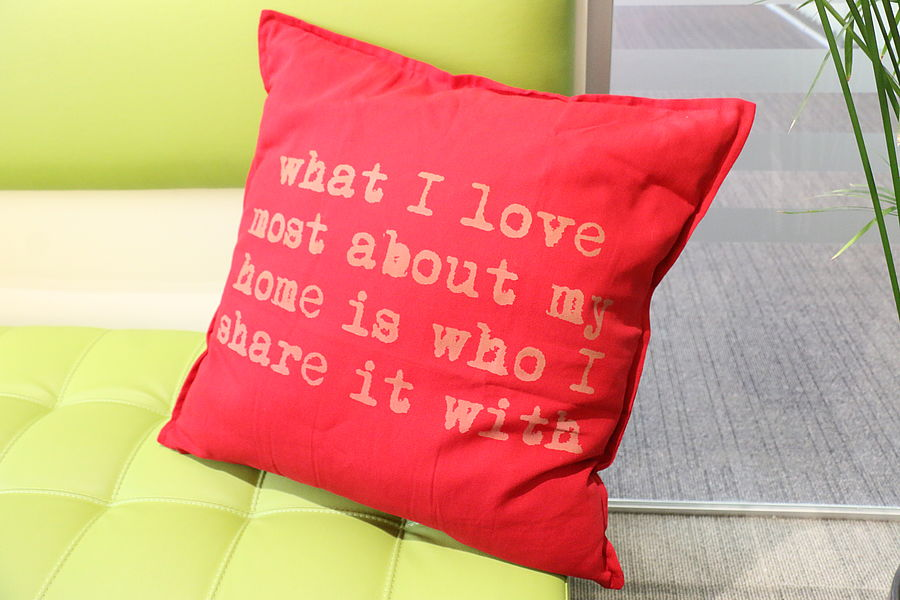

Laser technology is the ideal solution for processing textiles, allowing you to create highly customizable and unique products. Discover the many advantages of laser processing natural and synthetic textiles.

Natural textiles adapt extremely well to laser cutting and engraving technology, and some textiles even offer basic color change with laser engraving, depending on the material. Learn more about how to laser cut textiles and other materials.

Examples of natural textiles suitable for use with a laser machine:

- Cotton

- Denim

- Leather

- Linen

- Silk

Laser engraving dark natural textiles

Laser engraving denim or cotton fabrics that are darker in appearance can result in a beautiful “bleached” design. We recommend using a low laser power (up to approx. 20% at 100 watts), as well as engraving without Z offset depending on the specific material being processed.

CAUTION: Using more laser power than required or resolution that is too high can often result in your fabric being torn or the fibers dissolving either immediately or after the initial wash at the latest. A resolution of 250 to 500dpi is typically suitable, depending on the graphic.

Laser engraving light natural textiles

Achieving a dark laser engraving on light textiles will require deliberate defocusing (i.e. a Z offset of around 2-20 mm), depending on the material being processed. The distance between the lens and the material will change the spot size, so the further away the lens is, the larger the laser spot will be.

Laser cutting natural textiles

For cutting, use a frequency of 1000 to 3000 Hz. We also recommend turning on Air Assist during the cutting process, as well as using the smallest diameter nozzle to avoid dark edges.

Laser cutting and engraving synthetic textiles

Synthetic fabrics (such as plastics or polyester) perform very well to laser processing, and the heat from the laser beam will melt plastic in a controlled manner, providing fiber-free, sealed edges without any fraying. The laser engraving process allows for more tangible haptic effects to be achieved, making it exceptionally easy to enrich your products or create intricate and unique patterns in fabrics.

Examples of synthetic materials suitable for use with a laser machine:

- Carpet materials

- Microfiber

- Softshell

- Synthetic felt

- Synthetic leather (excluding any leather that contains PVC)

- Various fleece fabrics

- Velour

Laser engraving synthetic textiles

Some synthetic fabrics such as fleece, felt or leather react very well to laser engraving, because the material will melt once processed, allowing for great contrast. Depending on the specific material, homogeneous engraving can be achieved using a Z offset of 1 to 5 mm with a resolution of up to 500 dpi.

Some textiles are not able to be laser engraved however, e.g. thin synthetic fiber materials, as the heat from the laser beam will completely melt the material when processed. The grayscale matrix is a quick and easy way to test your fabric, to see if it allows for homogeneous engraving to be achieved.

Laser cutting synthetic textiles

Laser cutting synthetic fabric provides excellent processing results, and all individual fibers merge and become sealed from the plastic content of the textile. This saves both time and money as there is no need for additional material hemming, as well as fraying is prevented. Synthetic materials can be cleanly cut (i.e. clean cut edges with no smoke residue) with the right combination of speed and power, and it is important to make sure to avoid using power that is too high and speed that is too low. We recommend a frequency between 1000 Hz and 3000 Hz for the best results.

CAUTION: Some synthetic materials (especially synthetic leathers) will often contain PVC, which is extremely dangerous and not suitable for any type of laser processing. When attempting to process these materials, hazardous chlorine gas and dust can be released, which will endanger the laser operator as well as the functioning of the machine. Here we have provided you with a detailed overview of unsuitable materials for laser processing.

Determining the right parameters for engraving and cutting

Establishing the proper cutting parameters

Textiles are very diverse in composition and are made of natural or chemical fibers. Having a good understanding of the platform and configuration of your laser cutter will make it easier to select the proper parameters for your specific application.

When working with large geometries that have a substantial amount of straight lines, you will typically be able to cut through the material faster by using stronger laser power. With the Speedy series laser machines, speeds up to approximately 15% are possible and if you are looking to create precisely cut edges with small geometries, then reducing the speed and power of your laser may be required. With a Speedy laser machine, a maximum cutting speed of 3% can be used as a guide for a design similar to the one shown in the photo.

With an SP series laser cutter, the integrated hardware and software offer additional support for determining the correct parameters with optimized speed for a straight geometry. Depending on the laser power, speeds up to 100% are possible because the machine adjusts the actual values of the contour automatically, thus providing perfect cutting results.

Determining the engraving parameters

Using the grayscale matrix allows you to determine the proper engraving parameters yourself, in a quick and easy way.

TIP: The greater you defocus the machine lens (Z offset: approx. 0.5 – 20 mm), the darker the textile engraving will be. Adjusting the laser beam focus will alter the laser spot size, so when the beam is defocused, it will decrease the power density allowing for more material burning instead of allowing it to change into a gaseous form.

Laserflexx – as easy as iron-ons

LaserFlex is a multi-layered, superior-quality film specifically designed for use with laser technology. Enhance textiles by using designs, logos and lettering of your choice with a screen-like finish. Optimal laser settings will vary based on the speed and power of your specific laser machine. We recommend processing from the bottom up and setting your exhaust power to maximum capacity, so that any dust produced does not touch the parts already processed by the laser.