After the Second World War, the term “superalloy” appeared to describe a high-performance alloy. This type of material was specifically developed to extend the service life of aircraft components exposed to extreme high temperatures. High-temperature alloys are based on nickel, iron, and cobalt, and through the addition of alloy elements to achieve superfusion of various metal characteristics, they can work for a long time at a high temperature above 600℃ and certain stress, and become the pillar material of aerospace, petrochemical, racing, and other industries.

The characteristics and applications of Inconel 718

Inconel 718 is a precipitation-hardened nickel-chromium-iron alloy containing niobium and molybdenum. It was mass-produced in 1965. It can solid dissolve a variety of alloying elements and avoid the precipitation of harmful phases with low ductility. It can maintain high yield strength in high-temperature environments. Excellent plasticity, good processing performance and structural stability make it an ideal choice for industrial applications in many fields. According to statistics, more than half of the mass of materials used in aerospace engines are nickel-based superalloys, and the use of Inconel 718 has exceeded one-third of the total use of nickel-based alloys.

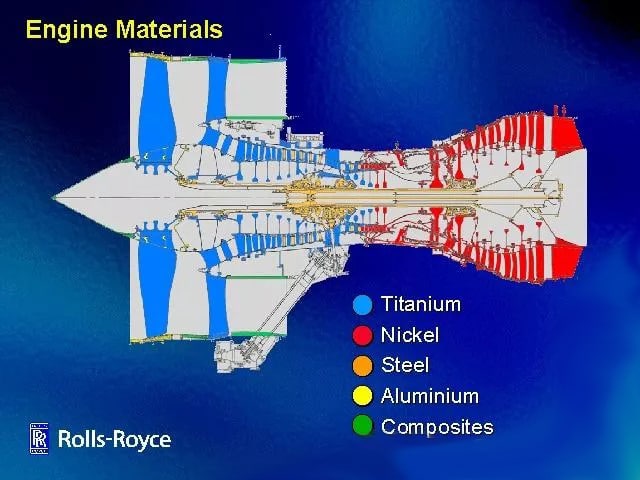

According to the Carnot cycle, running the engine at a higher temperature can improve energy efficiency, which in turn makes the engine more energy-efficient. From compressors, combustion chambers, turbines to casings that protect and support engines, from many stationary rotating parts in aerospace engines to various bolts and fasteners, Inconel 718 is widely used in the manufacture of high-temperature components for aero engines. Especially for today’s leading aerospace engines, Inconel 718 is used in greater quantities. One-third of the quality of GE’s famous CF6 engine is made of this alloy, while Inconel 718 alloy is used in P&W’s PW4000 engine. It is more than half the mass of the engine.

Comparison with stainless steel and titanium alloy

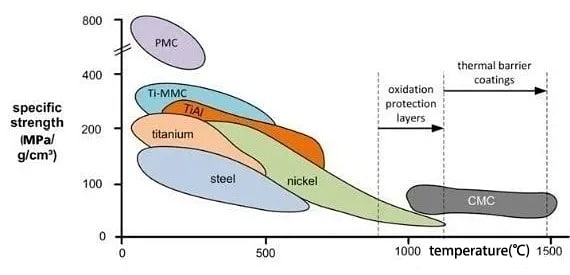

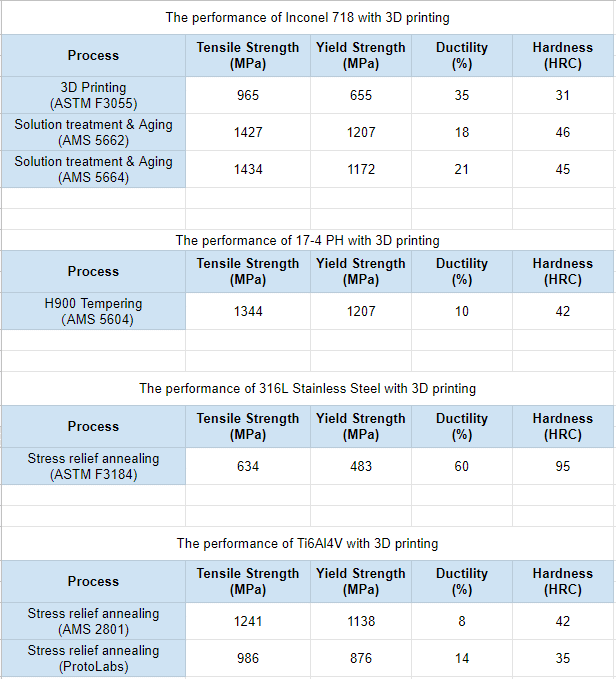

In terms of performance in harsh temperature environments, nickel-based alloys (such as Inconel 718) may be better than titanium alloys or steel. The oxidation protection layer of nickel-based alloys further improves the mechanical properties. The following table lists the properties of Inconel 718, stainless steel, and titanium alloys.

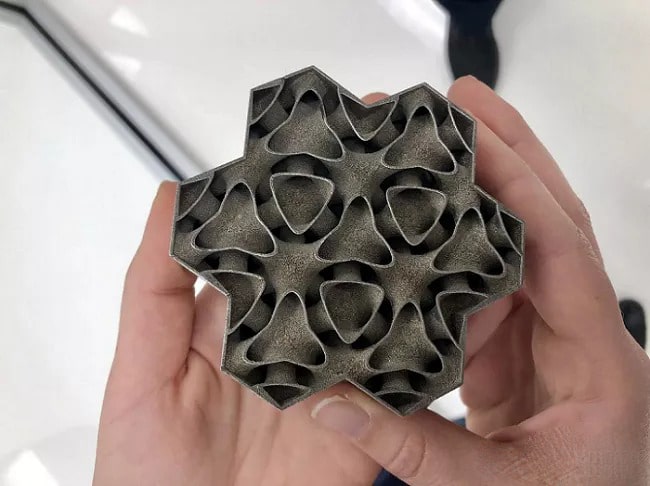

3D printing brings potentials to Inconel 718

The design required for nickel-based superalloys using non-3D printing processes may be challenging. When traditional manufacturing methods such as machining, forging or welding are used, annealing is often required before the process starts, and the high-temperature corrosion and creep resistance of the components will be affected. The results of additive manufacturing of Inconel 718 alloy show that the mechanical properties have not been sacrificed and can even exceed the performance of cast or forged parts.

In addition, Inconel 718 is a typical difficult-to-machine material due to its high cutting temperature and serious work hardening. For the complex geometries normally required in aerospace applications, the manufacture of Inconel 718 parts is often very difficult and costly.

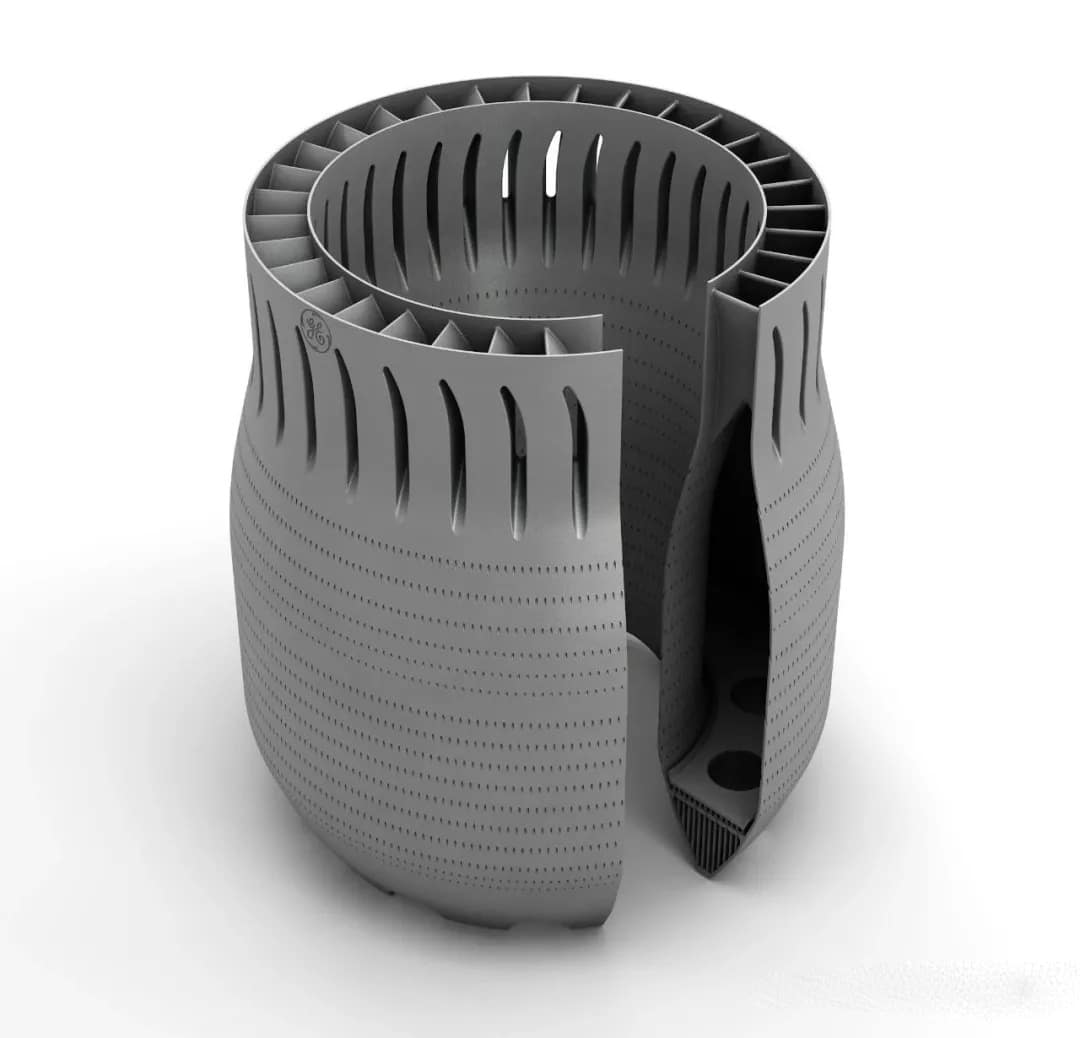

Aerospace companies such as GE Aviation have used 3D printed Inconel 718 in aircraft engine manufacturing. While ultimately achieving fuel and cost savings, design freedom, reduced parts, and improved supply chain efficiency have made additive manufacturing the focus of the aerospace industry.

The low-temperature properties of 3D printed superalloys also have application potentials, such as pipes and shells, low-temperature suspension and support systems, impeller or pump structures, valve stems, cooling pipes, heat pipes, heat insulation design, heat exchangers, and gases in high-porosity systems storage is very suitable for the application of high-strength superalloys, and its temperature range covers from -273℃ to 760℃.

The development of powder metal and the development of industrial-grade metal 3D printers have promoted applications in many industries, thus releasing the advantages of additive manufacturing of superalloys.