With over 85 thousand types of injection molding plastic materials to choose from, you can only imagine how overwhelming it can be for product designers, entrepreneurs, and others alike to pick just the right material to manufacture their product.

But don’t get discouraged — it is much easier to pick a material when you look into the overall material composition that plastics used for injection molding fall into. These are the top six materials used throughout the industry:

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide (Nylon)

- High-Density Polyethylene (HDPE)

- Polycarbonate (PC)

- ABS + PC Blend (mostly used for electronics enclosures)

There are thousands of variations within each material, so for the purpose of this article, we will be focusing on the main properties of each of these six categories, focusing on hardness, flexibility, weight, and cost.

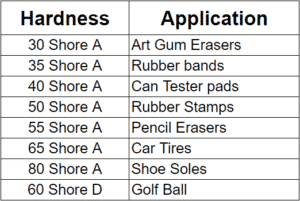

Material Hardness

Let’s start with the hardness property and see how each material category falls on the scale. The most common way to measure a material’s hardness, or resistance to indentation, is by using a device to measure shore hardness, which is in turn separated into type A and type D, measuring softer and harder plastics, respectively. The scale for both types varies from zero to 100. The hardness is also popularly referred to as Shore hardness, named after Albert Shore, who developed the durometer scale used to measure material hardness. Now let’s see how day-to-day things around us stack up on a shore scale:

As you see from the table above, different materials are used for different applications. It is extremely important to pick the right material for the right product application, taking into consideration usage, environmental conditions, type of abrasion, and even overall user experience/interaction with the product.

Illustrated below are how these top materials stack up regarding how soft or hard they are:

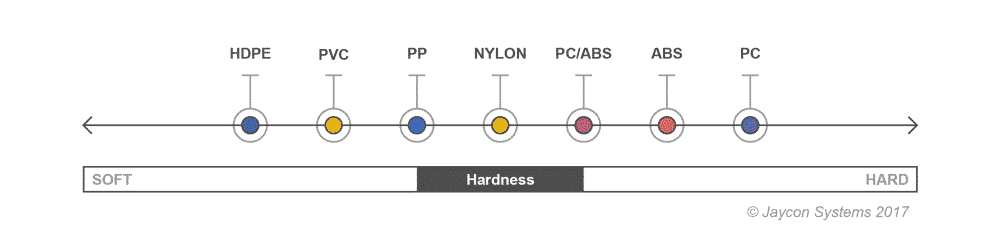

Material Flexibility

A common misconception is that all soft materials are flexible, and all hard materials are stiff. It is important to know the difference between the material being soft versus it being flexible. A material’s flexibility is its ability to bend under stress without breaking easily. Stiffness, however, is the resistance to bending under stress. A good example of a flexible product is an ABS ruler, even though it is more of a harder material. It would bend up to a certain point before it shows signs of failure. On the other hand, a Nylon ruler would rupture as soon as the load is applied to it.

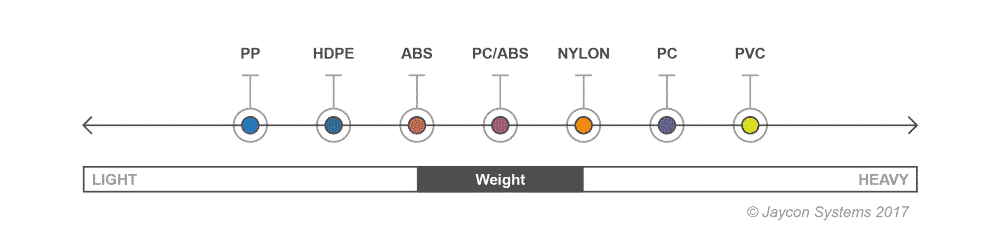

Material Weight

Material weight consequently plays another role in material selection. Ultimately, the density of a plastic polymer will determine how heavy or light the end product turns out to be.

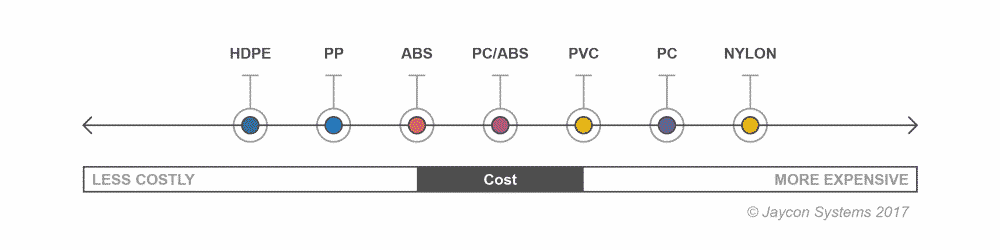

Material Cost

Material cost is certainly an important factor when it comes to manufacturing a plastic injection molded product, however, it is important to make material decisions based on the product application rather than cost alone. Below is a brief outline of cost comparison between the most common plastics used for injection molding.

Conclusion

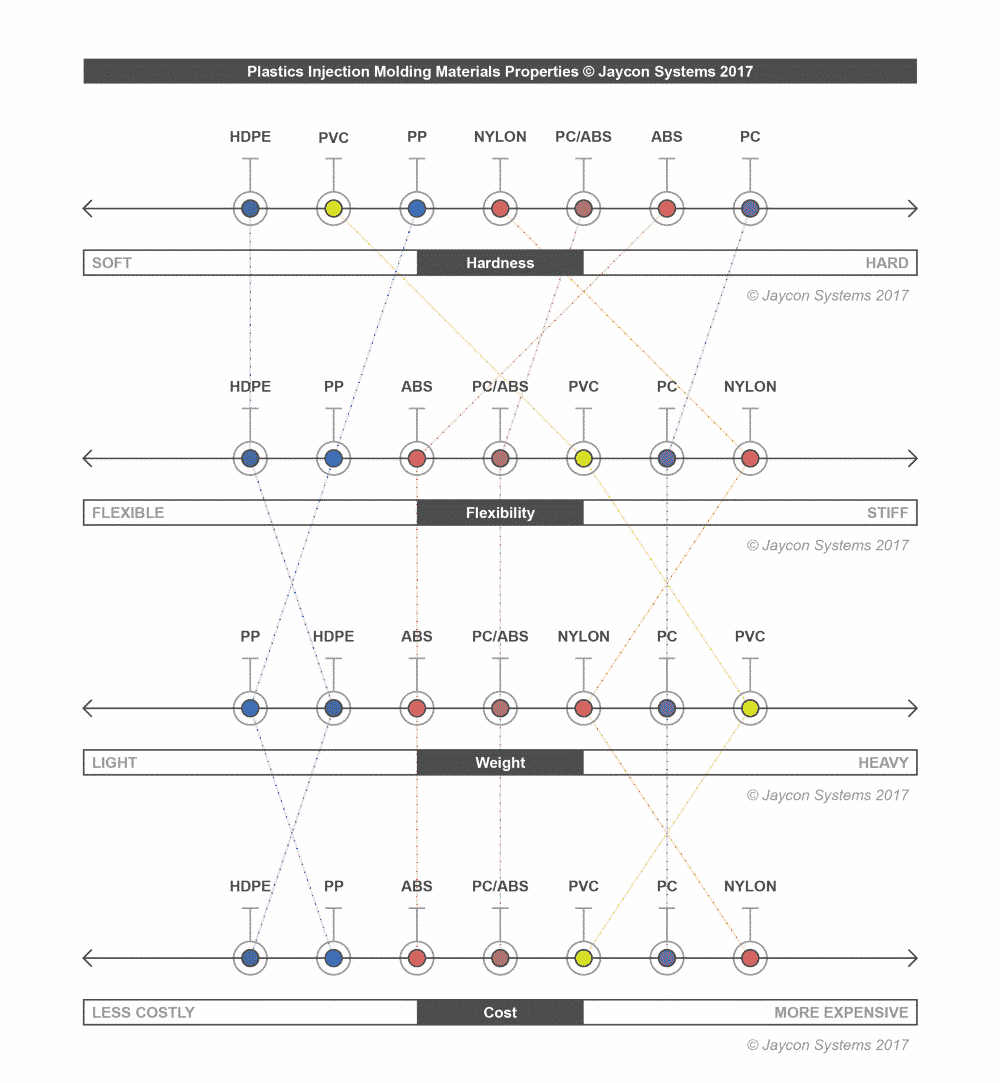

All materials have their own properties, and it is extremely important to look at the overall defining characteristics that come with each material category you choose. Keep in mind that if you believe the material is falling short of some properties, there is always fine-tuning through the use of additives and fillers to get the material properties just right — that’s how you end up with over 85,000 types of plastics — but we will leave that topic for another article. Check the table below and use the line corresponding to each material to quickly compare where it falls on each of the four different properties we talked about. If you are having trouble throughout the process of picking the correct material, FacFox can help.