Choosing the right lens can be tricky

The parameters are fine and the focus is set correctly, but somehow the engraving is not correct. Has this ever happened to you? This is most likely a lens issue. The correct lens is just as important as the right parameters and optimal focus adjustment.

To select the correct lens, you must consider the following:

- Output of your laser device

- Material

- Detail level of the graphics

- Resolution (dpi)

- Thickness of the material

The rule of thumb:

The more delicate and detailed the graphics are, the smaller the lens should be chosen. For cutting thick materials, lenses of maximum size are recommended. For detailed information, please see the table below.

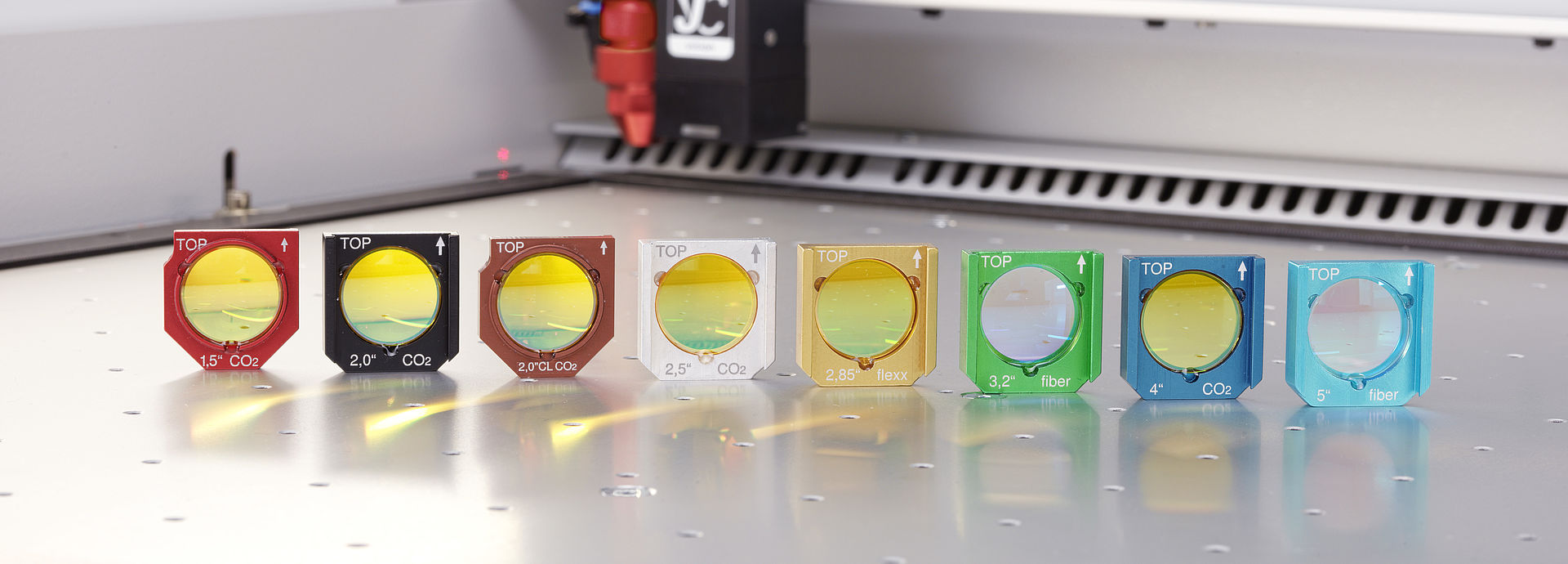

The Speedy and SP lens portfolio

The following table shows all the lenses available for the lasers and their applications.

| 1.5 inch CO2 | Graphics with fine detail, (resolution > 500 dpi), rubber stamps with thin letters | Lower laser power, thin materials (e. g. paper), acrylic < 6 mm, wood of medium hardness < 8 mm. |

|---|---|---|

| 2.0 inch CO2 | Graphics with medium detail and resolution (resolution 500 dpi; with reduced definition up to a resolution of 100 dpi), standard engraving | Medium laser power, acrylic < 8 mm, wood of medium hardness < 12 mm. |

| 2.0 inch CO2 clearance lens | Mainly used for cutting | See 2.0 inch lens. Increases the distance between laser head and material. Is especially useful if the increased distance is required due to the material and the graphic |

| 2.5 inch CO2 | Graphics with low detail, low resolution (< 500 dpi). Engraving on heat-sensitive materials (e. g. laminate) if large areas have to be removed completely | High laser power, acrylic <12 mm, wood of medium hardness <15 mm Better quality of edges during laser cutting than for lower focal distances |

| 2.5 inch CO2 clearance lens | Used mainly for cutting | See 2.5 inch lens. Increases the distance between laser head and material. Is especially useful if the increased distance is required due to the material and the graphic. |

| 2.85 inch flexx | Standard lens for Speedy flexx series. Is transmissive for both CO₂ lasers and fiber lasers. Both laser sources can be used without changing the lens.

Other characteristics as 2.5 inch CO2 lens or 3.2 inch fiber lens |

Characteristics as 2.5 inch CO2 lens or 3.2 inch fiber lens |

| 3.2 inch fiber | Standard lens for fiber lasers with extremely small focal diameter. Graphics with fine detail, ( > 500 dpi resolution) | |

| 3.75 inch CO2 | Lens for SP500 rotary engraving unit. Permits engraving of round objects with diameters of less than 50 mm | |

| 4.0 inch CO2 | Engraving by burning of wood, laser engraving of graphics with low detail with high laser powers | Foam rubber |

| 5.0 inch CO2 | Is not used for laser engraving | High laser power, acrylic < 25 mm, wood of medium hardness < 20 mm Better quality of edges during laser cutting than for smaller focal distances |

| 5.0 inch fiber | Lens for fiber lasers if materials that are not absolutely plane are to be labeled. The greater focal distance results in a greater tolerance during focusing. | |

| 7.5 inch CO2 (for SP1500) | Is not used for laser engraving | High laser power, acrylic < 40 mm, Better quality of edges during laser cutting than for smaller focal distances |

| Lens | When to use for engraving/marking | When to use for cutting |

Please note that not every lens is available for each device. We will be happy to assist you in selecting the ideal lens.

Technical features in plain terms

The following is a glossary of the terms used to discuss lenses.

Focal length

Distance between the lens and the point of the smallest beam diameter (= focus).

Focus

The area where the laser beam is optimally focused and converges to the smallest possible beam diameter.

Beam diameter

The diameter of the laser beam which becomes greater and greater before and behind the focus.

The longer the focal distance of the lens, the greater the beam diameter. The energy of the laser is focused by the lens onto a defined focal point. The greater the focal distance of the lens, the greater also the surface onto which the energy of the laser is applied. This may mean that if you use a large lens, the material is heated rather than cut.

Focus tolerance (depth of focus)

The area in which the beam has the smallest diameter.

The larger the lens (= the larger the focal length of the lens), the longer the focal tolerance. This means that the focus tolerance of a 5” lens will be twice that of a 2.5” lens. This is especially important if you want to cut through thick materials.