One key to achieving the perfect laser processed result is by selecting the proper nozzle, as the nozzle serves as the primary dust protectant for the systems lens. Find out more information here about choosing the correct nozzle for your application.

Nozzle selection

There are 3 different nozzle types to choose from:

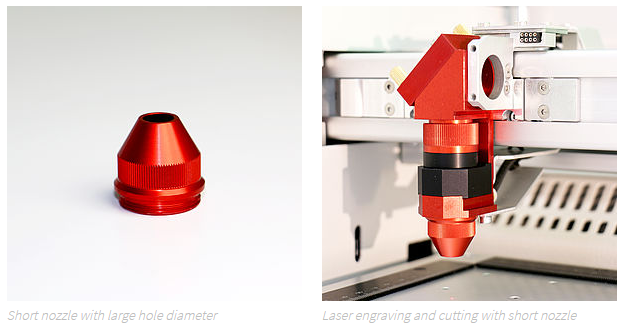

Short nozzle with large hole diameter (7mm)

The standard nozzle, which is the short nozzle with the large hole (7 mm diameter), is suited for both laser cutting and laser engraving applications.

When cutting, this nozzle is typically used for processing acrylic and creating a beautiful flame-polished edge, because the material is not cooled down as quickly.

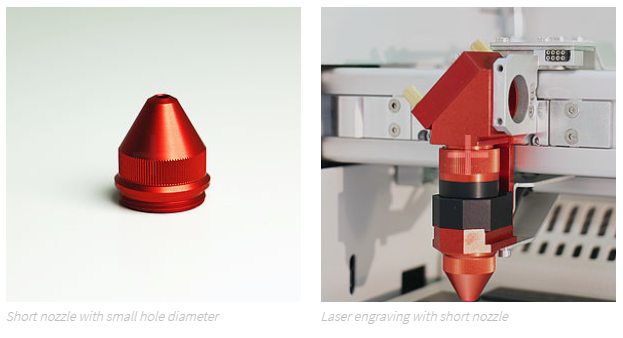

Short nozzle with small hole diameter (3mm)

The short nozzle with the small hole (3 mm diameter) is primarily used for cutting applications that produce and excess of smoke, such as wood. Because of its restricted opening, the airflow is concentrated and directed into the kerf, blowing any emerging smoke or cutting gases away.

This nozzle is not compatible for dust-intensive engraving applications, such as stamp rubber or plastics for example. Any dust produced will settle quicker at the nozzle opening and can block it, resulting in a burn hole on the lens.

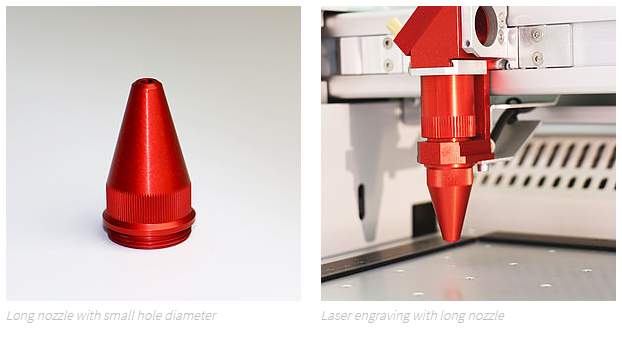

Long nozzle with small hole (3 mm diameter)

Designed to be used and combined with the 2.5” lens, there is also the long nozzle with a small hole (3 mm diameter). The properties of this nozzle match those of its short counterpart, and will compensate for the greater focal distance between the material and 2.5” lens.

Copper nozzles for laser cutting with compressed air

There are additional short copper nozzles available for laser cutting with compressed air on the SP500 that have a 1.7 mm diameter. Because of this especially small diameter, all airflow is directed into the kerf in an even more focused way. Therefore, with thicker materials such as wood or polycarbonate that is around 5 mm, you achieve an ideal laser cut. Based on the lens and focal distance that is used, there are also attachments available in four different lengths.