Plastic is a great material for CNC machining, as it offers a wide range of options for different applications and requirements. However, choosing the right plastic for your project can be challenging, as you need to consider various factors such as mechanical strength, stiffness, toughness, heat resistance, chemical resistance, optical clarity, biodegradability, cost, and processing difficulty.

In this guide, we have introduced some of the most common plastics used for CNC machining, their properties, advantages, and disadvantages, and how to select the best plastic for your needs. We hope this guide has helped you to understand the basics of plastic CNC machining and to make an informed decision for your project.

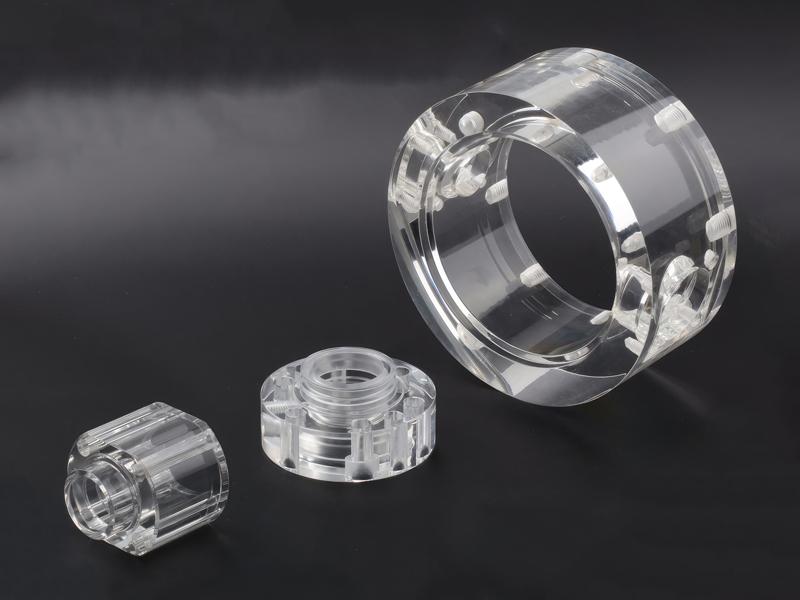

Acrylic (PMMA)

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic that offers excellent optical clarity, light transmission, and weather resistance. It is easy to machine and polish, and can be colored or tinted for various effects. Acrylic is often used for signage, displays, lenses, lighting fixtures, and decorative items.

Acrylic has a high tensile strength and modulus of elasticity, but it is brittle and prone to cracking or chipping under impact or stress. It also has a low heat resistance and can deform or melt at high temperatures. Acrylic is not resistant to solvents or chemicals, and can degrade under UV exposure over time.

Acrylonitrile butadiene styrene (ABS)

Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer that combines the strength and toughness of acrylonitrile and styrene with the flexibility and impact resistance of butadiene rubber. It is one of the most widely used plastics for CNC machining, as it is easy to cut, drill, tap, and glue. ABS has good dimensional stability and surface finish, and can be painted or coated for aesthetic purposes. ABS is commonly used for enclosures, housings, automotive parts, toys, and consumer electronics.

ABS has a moderate mechanical strength and stiffness, but it is not very resistant to high temperatures or UV radiation. It can also be affected by solvents or chemicals, and may warp or shrink during cooling.

Polyamide nylon (PA)

Polyamide nylon (PA) is a thermoplastic polymer that has high strength, stiffness, abrasion resistance, and chemical resistance. It also has good thermal stability and electrical insulation properties. PA is suitable for CNC machining, as it can be easily cut, drilled, tapped, and milled. PA is often used for gears, bearings, bushings, rollers, fasteners, and other mechanical parts that require durability and low friction.

PA has a high water absorption rate, which can affect its dimensional stability and mechanical properties. It also has a low impact strength and fatigue resistance at low temperatures. PA can be difficult to bond or paint due to its low surface energy.

Polycarbonate (PC)

Polycarbonate (PC) is a transparent thermoplastic that has high impact strength, toughness, and optical clarity. It also has good heat resistance and flame retardancy. PC can be CNC machined with standard tools and techniques, but it requires careful handling to avoid cracking or stress fractures. PC can be polished or coated for improved surface finish or scratch resistance. PC is widely used for lenses, windows, shields, helmets, enclosures, and other applications that require transparency and durability.

PC has a high coefficient of thermal expansion, which can cause warping or dimensional changes under temperature fluctuations. It also has a low chemical resistance and can degrade under UV exposure over time.

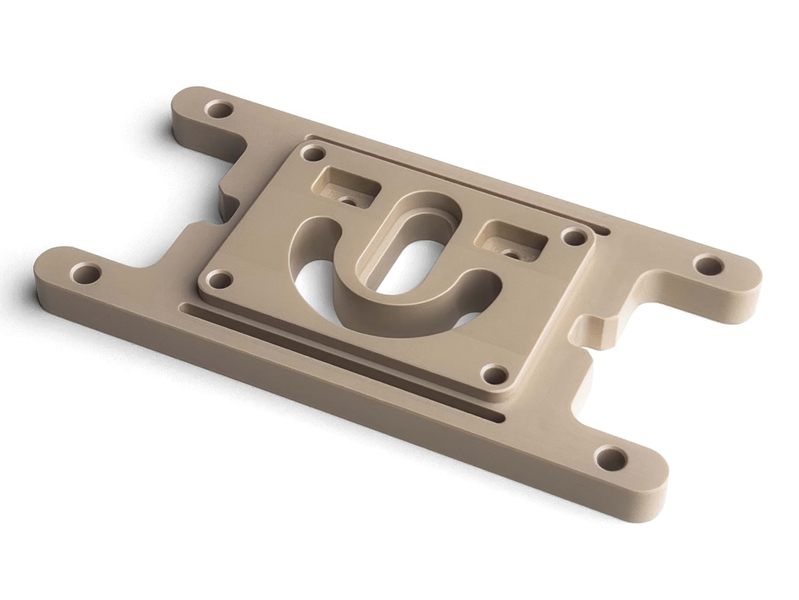

Polyether ether ketone (PEEK)

Polyether ether ketone (PEEK) is a high-performance thermoplastic that has exceptional mechanical strength, stiffness, modulus, and creep resistance. It also has excellent thermal stability, chemical resistance, and electrical insulation properties. PEEK can be CNC machined with specialized tools and techniques, but it requires careful control of cutting speed, feed rate, and coolant to avoid overheating or chipping. PEEK can be polished or coated for improved surface finish or wear resistance. PEEK is widely used for aerospace, medical, automotive, and oil and gas applications that require extreme performance and reliability.

PEEK has a high cost and is difficult to process compared to other plastics. It also has a high water absorption rate, which can affect its dimensional stability and mechanical properties.

Polyethylene (PE)

Polyethylene (PE) is a thermoplastic polymer that has high ductility, flexibility, and impact resistance. It also has good chemical resistance and electrical insulation properties. PE can be CNC machined with standard tools and techniques, but it requires low cutting speeds and sharp tools to avoid melting or deformation. PE can be welded or glued for joining purposes. PE is commonly used for packaging, containers, pipes, tanks, and other applications that require low cost and durability.

PE has a low tensile strength and stiffness compared to other plastics. It also has poor heat resistance and can deform or melt at temperatures above 80°C. PE is not resistant to UV radiation or oxidation, and can degrade over time.

Polypropylene (PP)

Polypropylene (PP) is a thermoplastic polymer that has high fatigue resistance, flexibility, and chemical resistance. It also has good thermal stability and electrical insulation properties. PP can be CNC machined with standard tools and techniques, but it requires low cutting speeds and sharp tools to avoid melting or deformation. PP can be welded or glued for joining purposes. PP is commonly used for automotive parts, medical devices, food packaging, and other applications that require low cost and versatility.

PP has a low tensile strength and stiffness compared to other plastics. It also has poor impact resistance at low temperatures and can become brittle or crack. PP is not resistant to UV radiation or oxidation, and can degrade over time.

Polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) is a thermoplastic polymer that has high hardness, rigidity, and flame retardancy. It also has good chemical resistance and electrical insulation properties. PVC can be CNC machined with standard tools and techniques, but it requires careful handling to avoid releasing toxic fumes or dust during machining. PVC can be glued or welded for joining purposes. PVC is widely used for pipes, fittings, cables, profiles, and other applications that require low cost and durability.

PVC has a low impact strength and toughness compared to other plastics. It also has poor heat resistance and can deform or melt at temperatures above 80°C. PVC is not resistant to UV radiation or oxidation, and can degrade over time.

Polystyrene (PS)

Polystyrene (PS) is a thermoplastic polymer that has high stiffness, hardness, and clarity. It also has good electrical insulation properties and low water absorption. PS can be CNC machined with standard tools and techniques, but it requires careful handling to avoid cracking or stress fractures. PS can be glued or welded for joining purposes. PS is widely used for disposable cups, plates, cutlery, packaging, and other applications that require low cost and transparency.

PS has a low impact strength and toughness compared to other plastics. It also has poor heat resistance and can deform or melt at temperatures above 70°C. PS is not resistant to solvents or chemicals, and can degrade under UV exposure or moisture over time.

Polyoxymethylene (POM)

Polyoxymethylene (POM), also known as acetal or Delrin, is a thermoplastic polymer that has high strength, stiffness, hardness, and wear resistance. It also has good dimensional stability and low friction. POM can be CNC machined with standard tools and techniques, but it requires sharp tools and adequate coolant to avoid overheating or chipping. POM can be glued or welded for joining purposes. POM is often used for gears, bearings, bushings, rollers, fasteners, and other mechanical parts that require precision and durability.

POM has a low impact strength and toughness at low temperatures. It also has poor heat resistance and can deform or melt at temperatures above 120°C. POM is not resistant to strong acids or bases, and can degrade under UV exposure over time.

Conclusion

| Material | Properties | Advantages | Disadvantages | Price |

|---|---|---|---|---|

| Acrylic (PMMA) | Transparent, weather-resistant, easy to machine and polish | Excellent optical clarity, light transmission, and aesthetic effects | Brittle, low heat resistance, not resistant to solvents, chemicals, or UV | $$ |

| Acrylonitrile butadiene styrene (ABS) | Tough, flexible, impact-resistant, easy to cut, drill, tap, and glue | Good dimensional stability and surface finish, can be painted or coated | Moderate mechanical strength and stiffness, not very resistant to high temperatures or UV radiation | $$ |

| Polyamide nylon (PA) | Strong, stiff, abrasion-resistant, chemical-resistant, good thermal stability and electrical insulation | Suitable for mechanical parts that require durability and low friction | High water absorption rate, low impact strength and fatigue resistance at low temperatures, difficult to bond or paint | $$ |

| Polycarbonate (PC) | Transparent, high impact strength, toughness, optical clarity, good heat resistance and flame retardancy | Suitable for applications that require transparency and durability | High coefficient of thermal expansion, low chemical resistance, can degrade under UV exposure over time | $$ |

| Polyether ether ketone (PEEK) | High-performance, exceptional mechanical strength, stiffness, modulus, and creep resistance, excellent thermal stability, chemical resistance, and electrical insulation properties | Suitable for extreme performance and reliability applications in aerospace, medical, automotive, and oil and gas industries | High cost and difficult to process, high water absorption rate | $$$$$ |

| Polyethylene (PE) | Ductile, flexible, impact-resistant, good chemical resistance and electrical insulation properties, easy to weld or glue | Suitable for low cost and durability applications such as packaging, containers, pipes, and tanks | Low tensile strength and stiffness, poor heat resistance, not resistant to UV radiation or oxidation | $ |

| Polypropylene (PP) | Fatigue-resistant, flexible, chemical-resistant, good thermal stability and electrical insulation properties, easy to weld or glue | Suitable for low cost and versatility applications such as automotive parts, medical devices, food packaging, etc. | Low tensile strength and stiffness, poor impact resistance at low temperatures, not resistant to UV radiation or oxidation | $ |

| Polyvinyl chloride (PVC) | Hard, rigid, flame-retardant, good chemical resistance and electrical insulation properties, easy to glue or weld | Suitable for low cost and durability applications such as pipes, fittings, cables, profiles, etc. | Low impact strength and toughness, poor heat resistance, can release toxic fumes or dust during machining | $ |

| Polystyrene (PS) | Stiff, hard, clear, good electrical insulation properties and low water absorption | Suitable for low cost and transparency applications such as disposable cups, plates, cutlery, packaging, etc. | Low impact strength and toughness, poor heat resistance, not resistant to solvents or chemicals | $ |

| Polyoxymethylene (POM) | Strong, stiff, hard, wear-resistant, good dimensional stability and low friction | Suitable for precision and durability applications such as gears, bearings, bushings, rollers, fasteners, etc. | Low impact strength and toughness at low temperatures, poor heat resistance, not resistant to strong acids or bases | $$ |

If you are looking for a reliable and professional plastic CNC machining service provider, look no further than FacFox. FacFox is a leading online platform that offers high-quality and affordable plastic CNC machining services for various industries and applications. FacFox has a network of experienced and certified CNC machinists who can handle any type of plastic material and any level of complexity.

FacFox also offers fast turnaround times, free online quotes, and online order tracking. Whether you need a prototype or a production run of plastic parts, FacFox can deliver them to you with accuracy, efficiency, and satisfaction. Visit www.facfox.com to learn more about FacFox’s plastic CNC machining services and to get started on your project today. Or you can get a quote via info@facfox.com.