TPU, or thermoplastic polyurethane, is a flexible and durable material that can be used for various applications. However, not all 3D printing technologies can handle TPU well. That’s why you should choose a 3D printing technology that can print TPU with high quality and precision: Multi Jet Fusion (MJF).

In this article, we will explain what MJF 3D printing TPU is, what are its benefits, what are some of its applications, and how you can get started with it.

What is MJF 3D Printing TPU?

MJF 3D printing TPU is a process that uses a special type of TPU powder and a fusing agent to create solid parts layer by layer. The powder is heated by a lamp and selectively fused by a print head that deposits the fusing agent. The fusing agent also acts as a color agent, allowing you to print in different colors.

TPU stands for thermoplastic polyurethane, a type of flexible plastic that has rubber-like elasticity and durability. TPU can withstand abrasion, tear, oil, grease and UV, making it suitable for a wide range of applications.

There are different grades of TPU powder available for MJF 3D printing, such as Ultrasint™ TPU01 and Ultrasint™ TPU90A. Ultrasint™ TPU01 has a shore hardness of 88A, while Ultrasint™ TPU90A has a shore hardness of 90A. The higher the shore hardness, the harder the TPU part is.

You can also adjust the hardness of MJF 3D printing TPU by changing the energy input during the printing process. For example, with Ultrasint™ TPU01, you can increase or decrease the shore hardness by increasing or decreasing the lamp power or print speed. However, this may also affect other properties of your prints, such as strength and durability.

What are the Benefits of MJF 3D Printing TPU?

MJF 3D printing TPU has several advantages over other 3D printing technologies and materials. Here are some of them:

- High resolution: MJF 3D printing TPU can produce parts with fine details, smooth surfaces and strong mechanical properties. The layer thickness can be as low as 0.08 mm, and the minimum feature size can be as small as 0.5 mm.

- Fast processing: MJF 3D printing TPU can print parts faster than other 3D printing technologies, thanks to its high lamp power and print speed. The average print time for a part with MJF 3D printing TPU is about 10 to 20 minutes per layer.

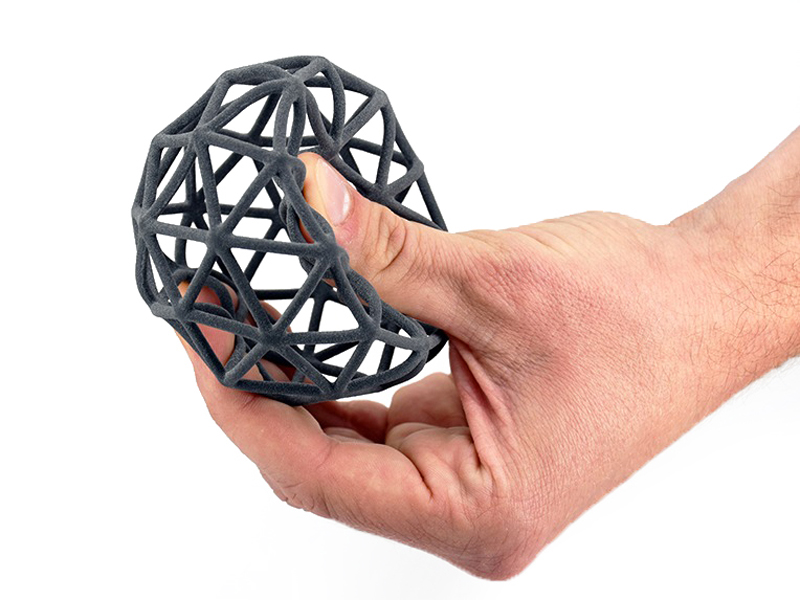

- Design freedom: MJF 3D printing TPU allows you to create complex and intricate lattice structures that are not possible with other 3D printing technologies. Lattice structures can reduce the weight and material usage of your parts while maintaining their strength and functionality. They can also enhance the performance of your parts by providing cushioning, shock absorption, ventilation or flexibility.

What’s the difference between MJF TPU, SLS TPU and FDM TPU 3D printing?

Technology

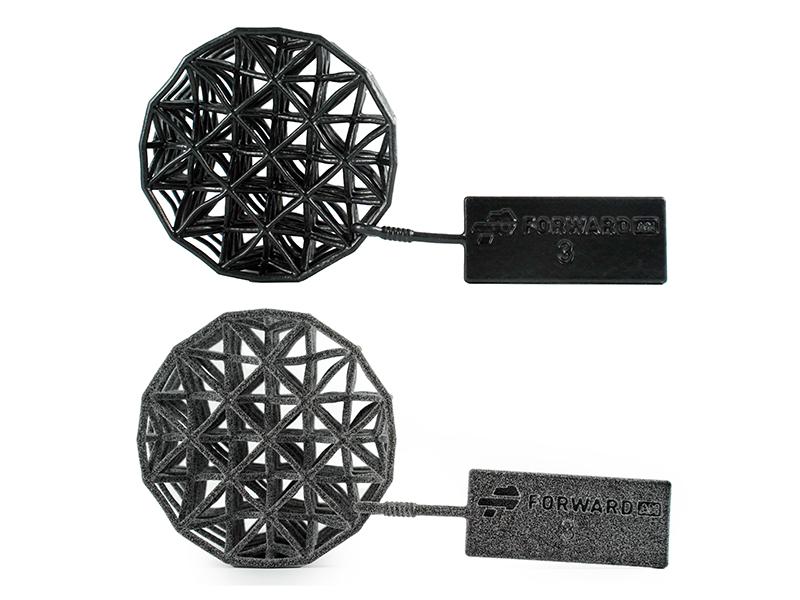

- MJF uses a fusing agent and an infrared lamp to selectively fuse the powder. The fusing agent also acts as a color agent, allowing you to print in different colors. But for now, FacFox could only print full-color nylon, while TPU has only two color options: raw (dark grey) and dye (black).

- SLS uses a laser beam to selectively sinter the powder. Sintering refers to heating the powder to the point where its outer surfaces melt and stick together.

- FDM uses a heated nozzle to melt and extrude a filament of TPU. The nozzle moves along the X-Y axis and deposits the material on the build platform.

Material Properties

MJF TPU, SLS TPU and FDM TPU are flexible and durable materials that can withstand abrasion, tear, oil, grease and UV. However, they have some differences in their hardness, strength and flexibility. Here we summarize the properties of all TPU materials we could offer printing services.

| Material | Technology | Brand | Hardness | Tensile Strength | Elongation at Break(X) | Elongation at Break(Z) | Color |

|---|---|---|---|---|---|---|---|

| SLS TPU Rubber | SLS | Ultrasint TPU 88A | 88-90A | 7-8 MPa | 270% | 130% | White |

| MJF TPU Rubber | MJF | Ultrasint TPU 88A | 88-90A | 7-9 MPa | 280% | 150% | Black or Gray |

| FDM PolyFlex TPU90 | FDM | Polymaker PolyFlex TPU90 | 90A | 30 ∓ 0.66 MPa | 586.8 ∓ 15.3% | / | Black or White |

| FDM PolyFlex TPU95 | FDM | Polymaker PolyFlex TPU95 | 95A | 29 ∓ 2.8 MPa | 330.1 ∓ 14% | / | Black or White |

| FDM PolyFlex TPU95 HF | FDM | Polymaker PolyFlex TPU95-HF | 95A | 23.11 ∓ 0.63 MPa | 462.3 ∓ 21.1% | / | Black or White |

For more information, please check our material – datasheet page.

What are Some Applications of MJF 3D Printing TPU?

MJF 3D printing TPU can be used for a variety of applications that require flexibility and durability. Here are some examples:

- Sport and leisure: You can create customized parts such as shoe soles, hoses or orthopedic models that fit your needs and preferences. MJF 3D printing TPU can provide you with parts that are comfortable, flexible and resistant to wear and tear.

- Automotive: You can produce parts such as seals, gaskets, bumpers or dashboards that are resistant to wear and tear and environmental factors. MJF 3D printing TPU can provide you with parts that are durable, flexible and shock-absorbing.

- Medical: You can fabricate parts such as surgical instruments, implants or prosthetics that are biocompatible and flexible. MJF 3D printing TPU can provide you with parts that are safe, comfortable and adaptable.

- Industrial: You can manufacture parts such as gears, belts, couplings or valves that are durable and reliable. MJF 3D printing TPU can provide you with parts that are strong, flexible and resistant to abrasion.

How Can You Get Started with MJF 3D Printing TPU?

If you are interested in using MJF 3D printing TPU for your next project, you need to find a reliable and professional 3D printing service provider that offers this technology and material. One of them is FacFox, a leading online 3D printing service provider that offers high-quality MJF 3D printing TPU at competitive prices and fast turnaround times.

Available Post-processing

MJF TPU is a flexible and durable material that can be used for 3D printing various applications. However, the raw finish of MJF tpu is coarse and has a dark grey color that may not suit some preferences.

To improve the appearance and performance of TPU, we offer two post-processing options: vapor smoothing and dyeing.

Vapor smoothing is a process that uses solvent vapor to melt and smooth the surface of TPU prints, resulting in a glossy and uniform finish.

Dyeing is a process that uses a special dye to change the color of TPU, giving it a more aesthetic appeal. We can dye MJF TPU into black, which is a popular choice for many customers.

To learn more about FacFox and their services, you can visit their website facfox.com, or contact them directly at info@facfox.com. They will be happy to answer any questions you may have about MJF 3D printing TPU or any other 3D printing technology or material.

We hope you enjoyed this article and found it useful. Thank you for choosing FacFox as your 3D printing partner!