Stereolithography, or SLA, emerged in the mid-1980s and established itself as a staple of additive manufacturing (AM) over the next decade. Since that time, SL’s ability to quickly and accurately create complex prototypes has helped transform the design world like never before.

As with other AM processes like selective laser sintering (SLS) and direct metal laser sintering (DMLS), SLA relies on lasers to do the heavy lifting. Parts are built by curing paper-thin layers of liquid thermoset resin, using an ultraviolet (UV) laser that draws on the surface of a resin turning it from a liquid into a solid layer. As each layer is completed, fresh, uncured resin is swept over the preceding layer and the process repeated until the part is finished. A post-build process is required on SLA parts, which undergo a UV-curing cycle to fully solidify the outer surface of the part and any additional surface finish requirements.

Stereolithography Resins

Unlike older generations of SLA, today’s machines offer a range of thermoplastic-like materials to choose from, with several “flavors” to mimic polypropylene, ABS, and glass-filled polycarbonate available. FacFox offers many variations of these materials:

- Polypropylene: A flexible, durable resin that mimics a stiff polypropylene. It can withstand harsh mechanical treatment and is great for fine details—sharp corners, thin walls, small holes, etc.

- Polypropylene/ABS blend: Strong, white plastic similar to a CNC machined polypropylene/ABS blend. It works well for snap fits, assemblies, and demanding applications.

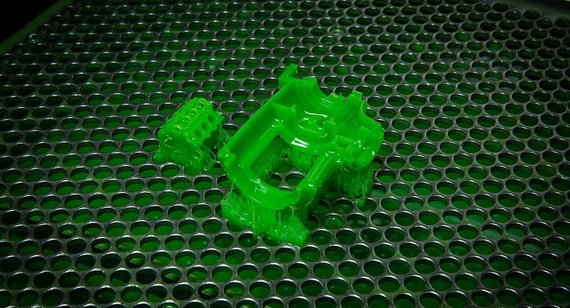

- ABS: Variations of ABS mimics include a clear, low-viscosity resin that can be finished clear; an opaque black plastic that blocks nearly all visible light, even in thin sections; a clear, colorless, water-resistant plastic good for lenses and flow-visualization models; and a green micro-resolution resin that enables production of parts with extremely fine features and tight tolerances.

- Polycarbonate: A ceramic-filled PC material that provides strength, stiffness, and temperature resistance, but can be brittle.

- SLArmor: A nickel-plated material that gives SLA-generated parts much of the strength and toughness associated with die cast aluminum.

Please note the term “thermoplastic-like.” This is an important distinction in that the mechanical properties of SLA materials only mimic those of their molded counterpart. If you need to pound on your prototype with a sledgehammer, or leave it in the sun for a few months, be aware that SLA parts do not provide the same strength and durability as parts that are sintered, cast, machined, or molded. This makes SLA the logical choice for prototype parts where validation of form and fit—but not necessarily function—is the most important factor. Customer service engineers at FacFox can help guide you during material and manufacturing process selection if help is needed.

SLA Layer Thickness and Resolution

Despite differences in material properties, SLA is the clear winner over SLS in terms of part accuracy and surface finish. Normal, high, and micro resolutions are available, providing layer thicknesses ranging from 0.004 to 0.001 in. and part features as small as 0.002 in. This means very fine details and cosmetic surfaces are possible, with minimal “stair stepping” compared to printed parts built by processes like fused deposition modeling (FDM).

SLA also has the edge in part size—need a prototype of a new luggage casing, or a lawnmower shell? There’s a good chance SL can accommodate. FacFox current max build size is 29 in. by 25 in. by 21 in. (736mm by 635mm by 533mm).

SLA is also an excellent choice for prototyping microfluidic devices. Our microfluidic fabrication process allows engineers to accurately test parts that will later be injection molded, avoiding the hassles and high cost of photolithography. If you’re designing a protein sensor, micro-pump, or lab on a chip, for example, SLA prototyping might be just the ticket.

Other Design Considerations for SLA Parts

Stay away from extremely small holes as well, since the relatively high viscosity of the photo-curable resin used with SL can pose challenges during the post-build process. If you’re inventing a newfangled angel hair pasta strainer, one with holes smaller than 0.005 in., SLA is probably not the best choice for a prototype. Thin walls should be monitored as well. The lid for a hi-tech sandwich container, for example, should have walls no less than 0.030 in. to 0.040 in. thick.

Bear in mind that we may create temporary structures to support your part during the build process, but these are removed prior to delivery and typically little evidence of their existence is found. We may also choose to orient the workpiece to facilitate a better build, in which case the cosmetic appearance of some surfaces can be affected—if certain cosmetic features on your part require an elevated level of surface finish, please indicate those surfaces when submitting your design.

Finishing Options

Speaking of smooth surfaces, FacFox offers plenty of options for finishing SLA parts. Most customers opt for light sanding to remove the aforementioned nibs left from supports, followed by a fine bead blast. Parts can be shipped “as is” and will show some evidence of the support structures. There are also several coating choices available—aside from the nickel SLArmor, painting (with color matching and masking services available), clear coat, texturing, and even custom decals are also possible.

As for preferred 3D CAD file formats for SLA, FacFox accepts STL files. Most commercial CAD systems can generate STL files, the native format of any SLA machine, but if yours doesn’t have this capability, our advice is to submit a neutral file format—such as an IGES or STEP file. But steer clear of the freeware STL generators littering the internet. Some tend to create incomplete STL files, meaning additional rework time and delayed production.

SLA plays an important step in the design process. It bridges the gap between digital models and machined or injection molded parts, giving people the ability to touch and feel prototype designs within days. Costly mistakes can be avoided, development costs reduced, and better products built in the long run.

Check out facfox.com to learn more about stereolithography and the key design guidelines for building better SLA parts.