When it comes to producing plastic parts in prototyping and low-volume applications, there are three main options: 3D Printing, Urethane Casting, and Low-Volume Injection Molding. Which is best for your needs?

First, let’s quickly define each of the techniques:

- 3D Printing is an additive process of creating a plastic or metal object from a 3D model, using a machine that either lays down thin layers of material in succession, or focuses a laser on powder or liquid to melt/harden the layers.

- Urethane Casting is the process of first creating a mold (either 3D printed or milled aluminum), then using that mold to make multiple castings of a product out of certain types of rubber or plastic that cure at room temperature.

- Low-Volume Injection Molding involves using a metal mold (either aluminum for low volume or steel at higher volume) to make castings of a product out of melted plastic or metal.

There are differences in the capabilities and costs associated with each, and each has advantages for specific applications. Which one is better for you depends on the requirements of your particular project.

Some projects might be best suited to one over the others, while other projects might necessitate using more than one of the techniques.

To help you compare the techniques methods and determine which one (or more) best for any particular project, we developed this table:

| Variable | 3D Printing | Urethane Casting | Low-Volume Injection Molding |

| Ideal Quantities | 1-50 units | 5-250 units | 250+ units |

| Surface/Part Detail | Not as good for highly intricate surfaces | Picks up subtle surface details | Creates parts with high levels of detail |

| Materials | Limited range of plastic at the low end, though high-end 3D printing supports a broader plastic and metal materials | Limited range of materials, typically rubber or plastic that cure at room temperature | Broad range of materials, both plastic and metal in melted form (starting with beads or powder) |

| Fixed Costs –Equipment & Mold | 3D printers range from $500 to $500,000 or moreNo mold needed. | Very little required equipmentLow mold cost. 3D printed plastic for prototypes, Aluminum for low-volume, harder materials. | Equipment $10-20k on low endMedium to high mold cost. Aluminum for low volume (1-10,000), steel for higher volume (10,000+) |

| Per-Unit Cost | High per-unit cost | Moderate to low per-unit cost | Very low per-unit cost especially at high volume |

| Domestic vs. Off-shore production | Ideal for US-based production | Ideal for US-based production | US-based production only for short lead-times, high budget, lower volume |

| Ideal Application | Prototyping & iterative design | Creating replicas | High-volume production |

Urethane Casting vs. Plastic Injection Molding

Urethane casting and injection molding are both manufacturing processes used to create plastic parts. There are some similarities between the two processes, and also some very important differences.

Similarities

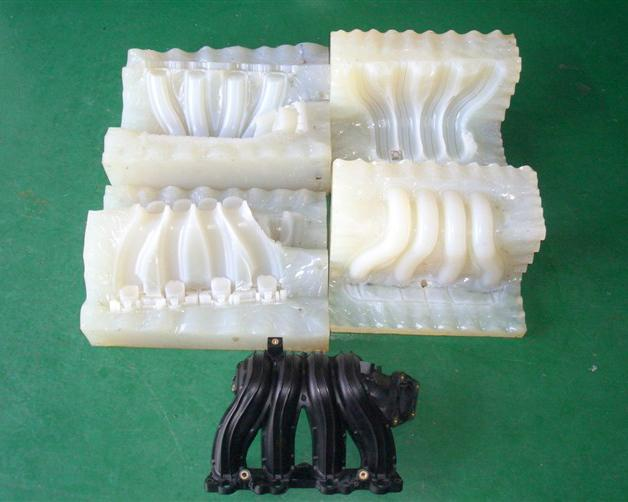

One of the most obvious similarities between the two processes is that they both use a mold to create the parts. In injection molding, the mold consists of a two-part “hard” mold typically made out of steel or aluminum. The A-side (cavity) comes together with the B-side (core) to form a void into which melted plastic is injected to form the plastic part.

Urethane casting, on the other hand, uses a poured and cured silicone “soft” mold. The cavity in the silicone mold is formed by pouring the liquid silicone around a “master pattern,” which is a model for the end parts to be made from, and is created by 3D printing, CNC machining, or an actual part. There is still an A-side and a B-side, which are created by cutting the silicone mold in half once it has cured with the master pattern in it. Those are the major similarities.

Differences

The first difference between the two processes is durability. A hard tool used in injection molding can run thousands of parts per day and last for hundreds of thousands of cycles. It is built to withstand the high heat and stress of the process, and is therefore designed for producing large volumes of parts with speed, consistency and a low piece price for mass production. A silicone mold, on the other hand, is not durable enough to last for more than about 20-25 parts. It is therefore used as a low-volume or prototype manufacturing method.

Another difference is cost. Silicone molds for urethane casting can cost as little as hundreds of dollars, versus the thousands (or even hundreds of thousands) of dollars for injection mold tooling. In addition, there is the speed factor – soft silicone molds can be produced much more quickly than the weeks it typically takes to machine injection mold tooling.

When it comes to part quality, both methods produce parts that are robust, and generally have more toughness and impact resistance than parts produced by additive manufacturing (3D printing). Urethane casting can even produce parts with more strength than injected molded parts, and the silicone molds have the ability to reproduce very fine details in surface finish.

Considering all these similarities and differences, the deciding factor usually comes down to volume. For high volumes, injection molding will be advantageous. For low volumes and prototypes, urethane casting is faster and less expensive.