CNC machining is a process that uses computer-controlled machines to create precise parts of various sizes and shapes. CNC machining can offer efficient, high-quality, and flexible manufacturing solutions, but it also involves some challenges and difficulties. In this article, we will explain the main challenges of large vs small part CNC machining, and how to cope with and overcome them.

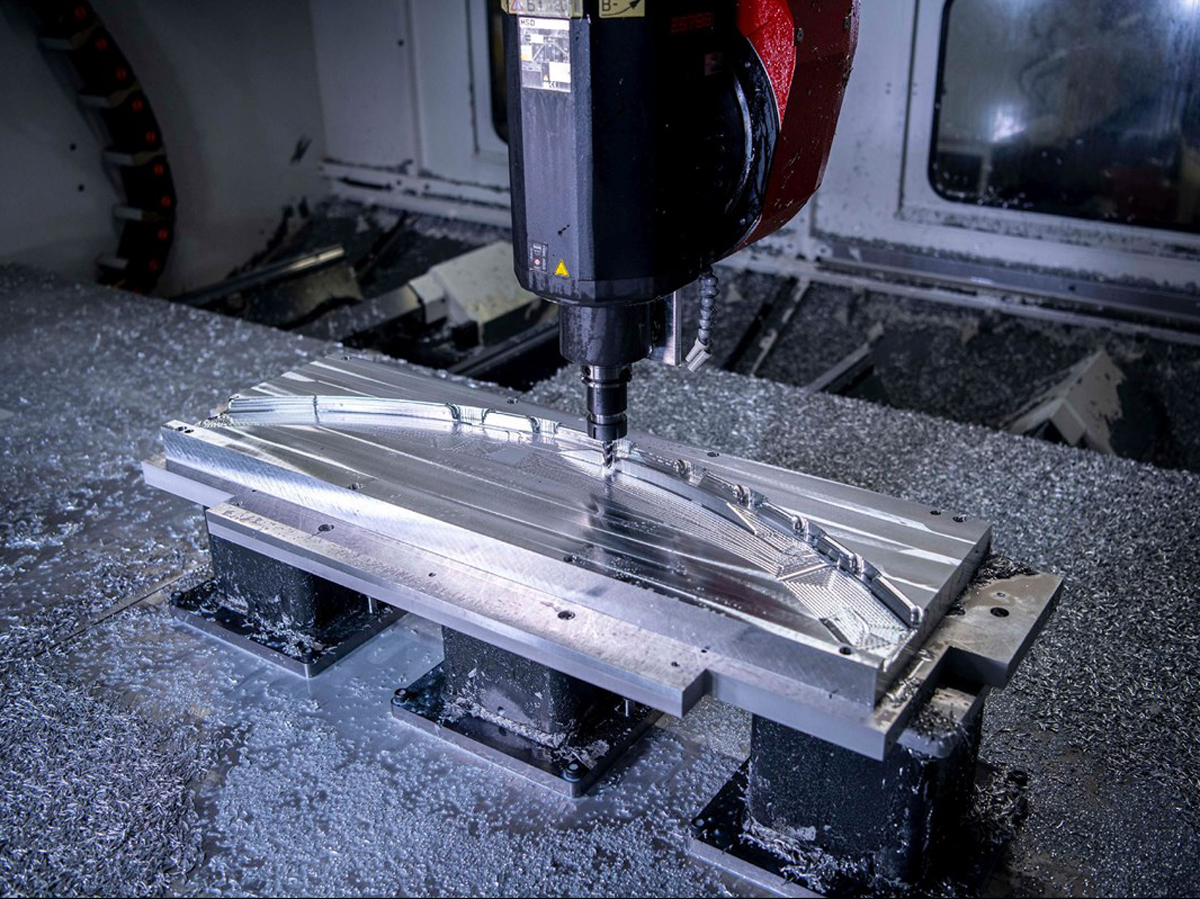

What are the challenges of large part CNC machining?

Large part CNC machining refers to the machining of parts that exceed the size that regular CNC machines can accommodate, such as parts that are over 1 meter or longer. Large part CNC machining usually requires special equipment, techniques, and experience to ensure the quality and accuracy of the parts. Here are some of the challenges of large part CNC machining:

Equipment limitations

Large part CNC machining requires CNC machines that have enough travel, rigidity, and power to withstand the large cutting forces and torques, and maintain stable operation. Moreover, large part CNC machining also requires suitable fixtures, tools, and auxiliary equipment, such as cranes, rotary tables, or indexing heads, to securely fix, move, and position the parts.

Material costs

Large part CNC machining usually requires larger raw material blocks, which increases the material costs and waste. Therefore, large part CNC machining needs to consider the material utilization and optimization rate in the design stage, to reduce the cutting amount and scrap amount.

Machining time

Large part CNC machining usually requires longer machining time, because the parts themselves are larger, and they may need multiple tool changes, fixture changes, or position changes. Therefore, large part CNC machining needs to consider optimizing the tool path, reducing the air cutting, increasing the feed rate and cutting speed, etc., in the programming stage, to shorten the machining time.

Machining accuracy

Large part CNC machining usually requires higher machining accuracy, because the parts may have higher tolerance requirements or fit with other parts. However, it is also prone to various factors that can cause machining errors, such as thermal deformation, gravity deformation, tool wear, fixture loosening, etc. Therefore, large part CNC machining needs to take some measures in the machining process, such as temperature control, compensation calculation, online detection, etc., to ensure the machining accuracy.

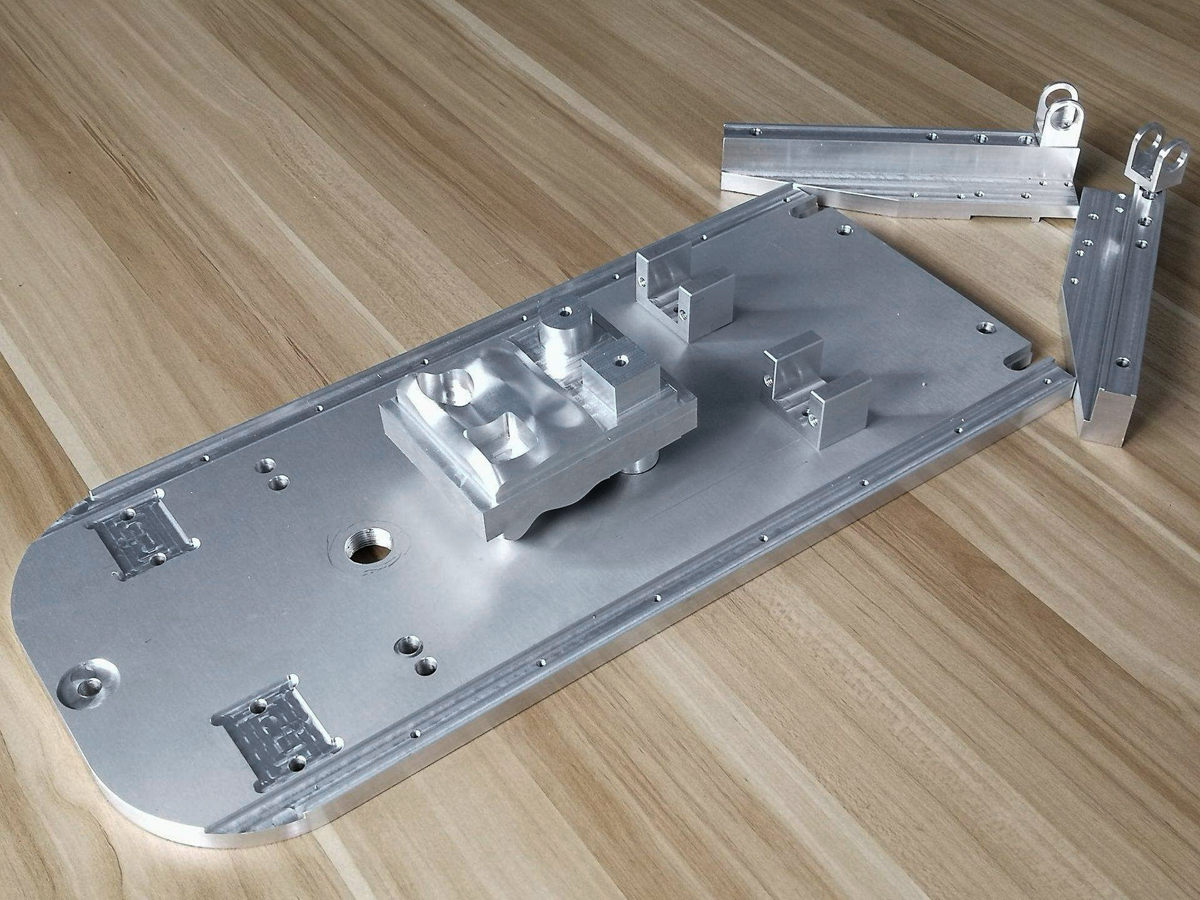

What are the challenges of small part CNC machining?

Small part CNC machining refers to the machining of parts that are small or fine in size, such as parts that are less than a few millimeters or even a few microns. It usually requires high-precision, high-speed, and high-flexibility CNC machines to meet the complexity and diversity of the parts. Here are some of the challenges of small part CNC machining:

Equipment requirements

Small part CNC machining requires CNC machines that have high precision, high speed, and high flexibility to adapt to the small size and complex shape of the parts. Moreover, it also requires suitable fixtures, tools, and measuring equipment, such as microscopes, probes, or optical instruments, to accurately fix, cut, and detect the parts.

Material selection

Small part CNC machining usually requires using special materials, such as metals, plastics, ceramics, or composite materials, to meet the function and performance requirements of the parts. However, these materials may also have some limitations or difficulties, such as brittleness, deformability, melting point, or hard-to-cut properties. Therefore, small part CNC machining needs to consider the characteristics and applicability of the materials in the material selection stage, to avoid machining problems or failures.

Machining quality

Small part CNC machining usually requires high-quality machining results, because the parts may have higher surface roughness or edge quality requirements. However, it is also prone to various factors that can cause machining defects, such as cutting force, cutting temperature, chip clogging, tool vibration, etc. Therefore, small part CNC machining needs to take some measures in the machining process, such as choosing appropriate cutting parameters, tool materials and coatings, cooling lubrication methods, etc., to ensure the machining quality.

How to choose a suitable CNC machining service provider?

Whether you need large or small part CNC machining, you need to choose a suitable CNC machining service provider to meet your needs. A suitable CNC machining service provider should have the following characteristics:

Equipment capability

A suitable CNC machining service provider should have enough and good CNC machines to accommodate different sizes and shapes of parts CNC machining. They should be able to provide various types of CNC machines, such as CNC lathes, CNC milling machines, CNC drilling machines, CNC grinding machines, etc., as well as various auxiliary equipment, such as rotary tables, indexing heads, cranes, etc.

Technical level

A suitable CNC machining service provider should have high-level technical personnel, including designers, programmers, operators, inspectors, etc. They should be able to design and optimize the part drawings and programs according to the customer’s requirements and specifications, operate and maintain the CNC machines and tools, inspect and verify the part quality and accuracy.

Quality assurance

A suitable CNC machining service provider should have a sound quality management system, including quality standards, quality control, quality improvement, etc. They should be able to guarantee that the parts meet the customer’s requirements and expectations, comply with the relevant regulations and standards, and provide quality certificates and reports.

Cost-effectiveness

A suitable CNC machining service provider should have a competitive and transparent pricing for their CNC machining services. They should be able to provide instant quotes and breakdowns for the parts, including the material costs, machining costs, shipping costs, etc. They should also be able to offer discounts or incentives for bulk orders or long-term cooperation.

How FacFox CNC machining services can help you

If you are looking for high-quality, cost-effective, and fast CNC machining solutions for your large or small part projects, FacFox CNC machining services can help you. FacFox is a leading online manufacturing platform that offers a wide range of CNC machining services for various applications. FacFox can offer:

- Optimize your parts for CNC machining using our expert advice

- Choose from a variety of materials, finishes, tolerances, and quantities for your parts

- Get instant quotes and transparent pricing for your parts

- Get your parts manufactured with high-quality CNC machines and tools by our experienced engineers

- Get your parts delivered fast with our global network of partners and logistics

Whether you need prototypes or production parts, FacFox can provide you with the best CNC machining solutions for your large or small part projects. Contact us today via info@facfox.com to get started!😊