Polyurethane (PU) is a synthetic resin that has many applications in various industries, such as automotive, medical, construction, and textile. PU products can have different properties, such as elasticity, hardness, tear strength, chemical resistance, flame resistance, abrasion resistance, and strength, depending on the mixture of ingredients and the molding process.

Ingredients

The main ingredients for PU manufacturing are diisocyanates and polyols. Diisocyanates are a group of versatile building blocks that react with polyols to form urethane groups (-NHCO2), which link the polymer chains together. There are different types of diisocyanates and polyols that can be used to create different types of PU products.

Molding Processes

There are different ways to create PU products using different molding processes. Some of the common ones are:

Compression Molding

Compression molding is a method that uses a heated mold and a heated compression material. The compression material is usually a preformed PU sheet or a liquid PU mixture. The material is placed into the mold cavity and then pressed by a hydraulic press. The heat and pressure cause the material to flow and fill the mold cavity. The mold is then cooled and opened to release the product.

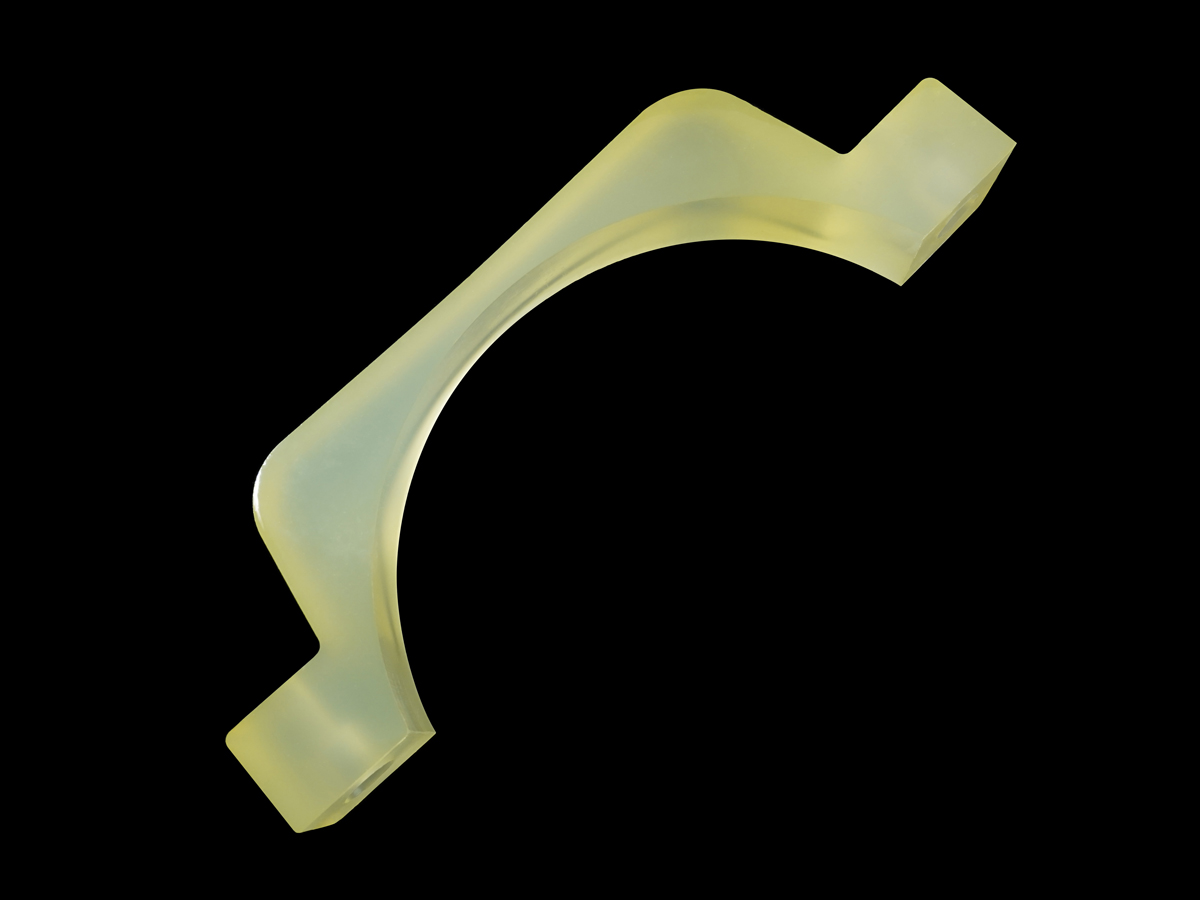

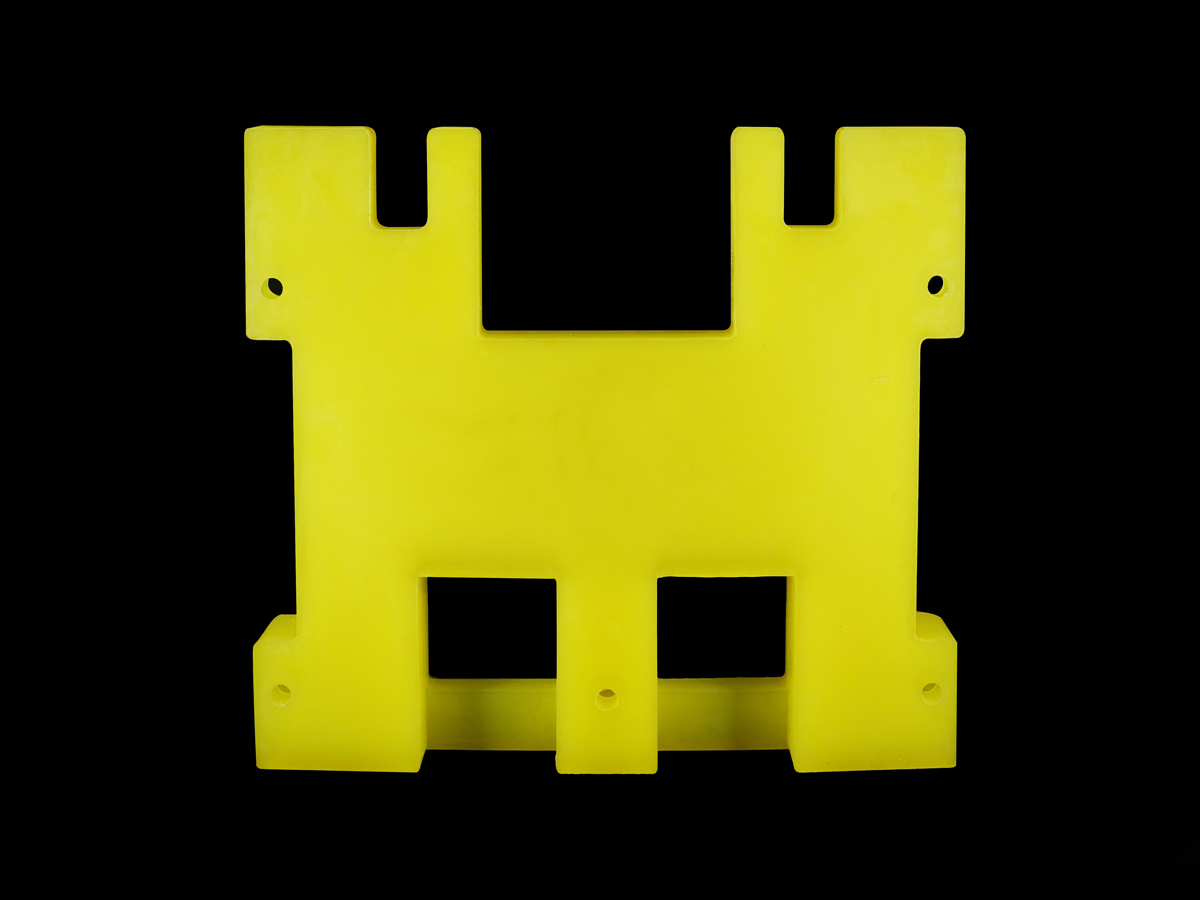

It is suitable for making solid or semi-solid PU products with complex shapes and high dimensional accuracy. It can also produce products with different colors and textures by using different compression materials.

However, compression molding has some disadvantages, such as high energy consumption, long cycle time, high waste generation, and limited design flexibility.

Injection Molding

Injection molding is a method that uses a strong metal mold and a liquid PU mixture. The liquid PU mixture is injected into the mold cavity under high pressure by a screw or a plunger. The mold is then cooled and opened to release the product.

Injection molding offers the benefit of high volume production with low waste generation. It can also produce products with fine details and smooth surfaces.

However, injection molding requires high initial investment for the mold and the injection machine. It also has some limitations in terms of product size, shape, and thickness.

Blow Molding

Blow molding is a method that uses a hollow metal mold and a liquid PU mixture. The liquid PU mixture is shaped into a preform with a hole in one end. The preform is then placed into the mold cavity and inflated by air or gas. The inflated preform conforms to the shape of the mold cavity. The mold is then cooled and opened to release the product.

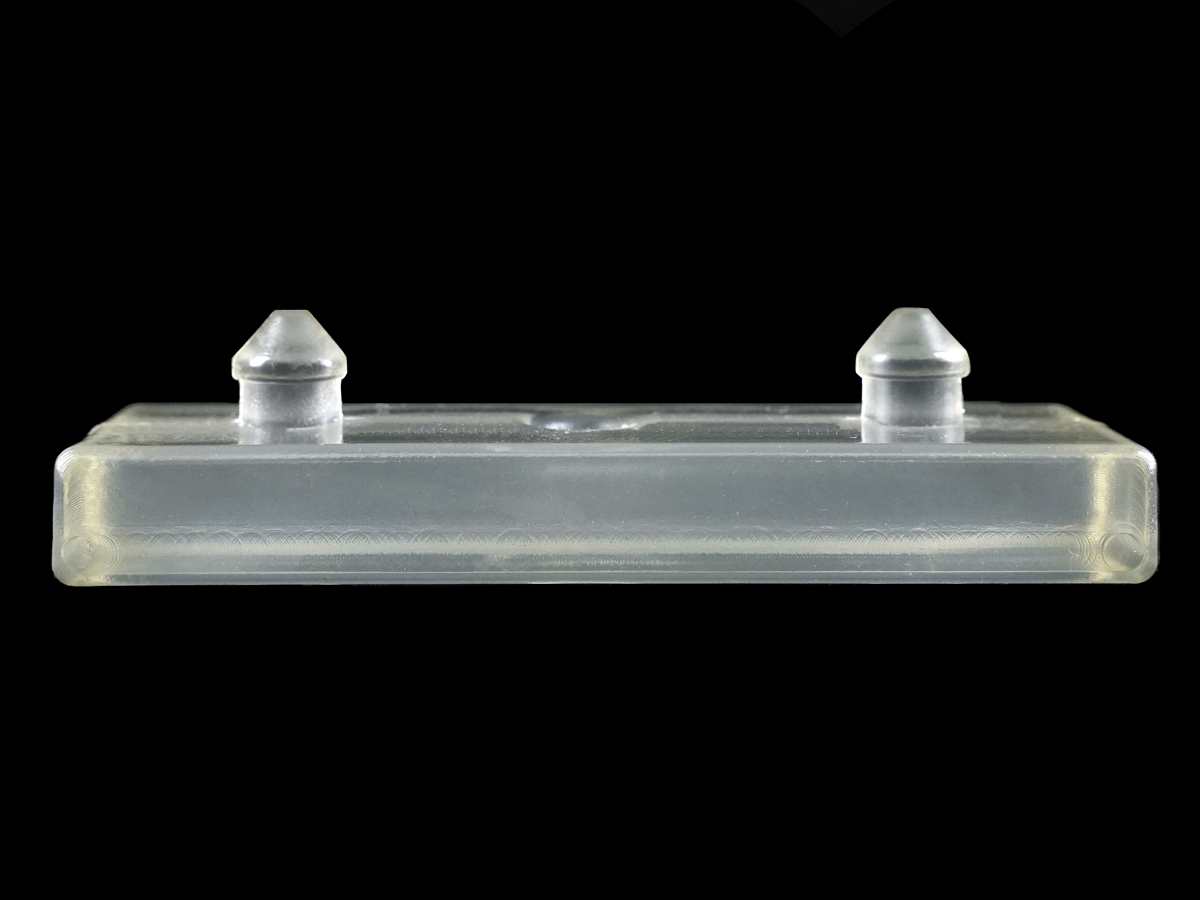

It is suitable for making hollow or thin-walled PU products with uniform wall thickness and high strength. It can also produce products with complex shapes and large sizes.

However, blow molding has some drawbacks, such as low production rate, high material consumption, high energy consumption, and difficulty in controlling the wall thickness distribution.

Extrusion Molding

Extrusion molding is a method that uses a heated barrel and a screw or a ram. The barrel contains a liquid PU mixture that is pushed by the screw or the ram through a die at the end of the barrel. The die shapes the liquid PU mixture into a continuous profile that exits the barrel. The profile is then cooled and cut into desired lengths.

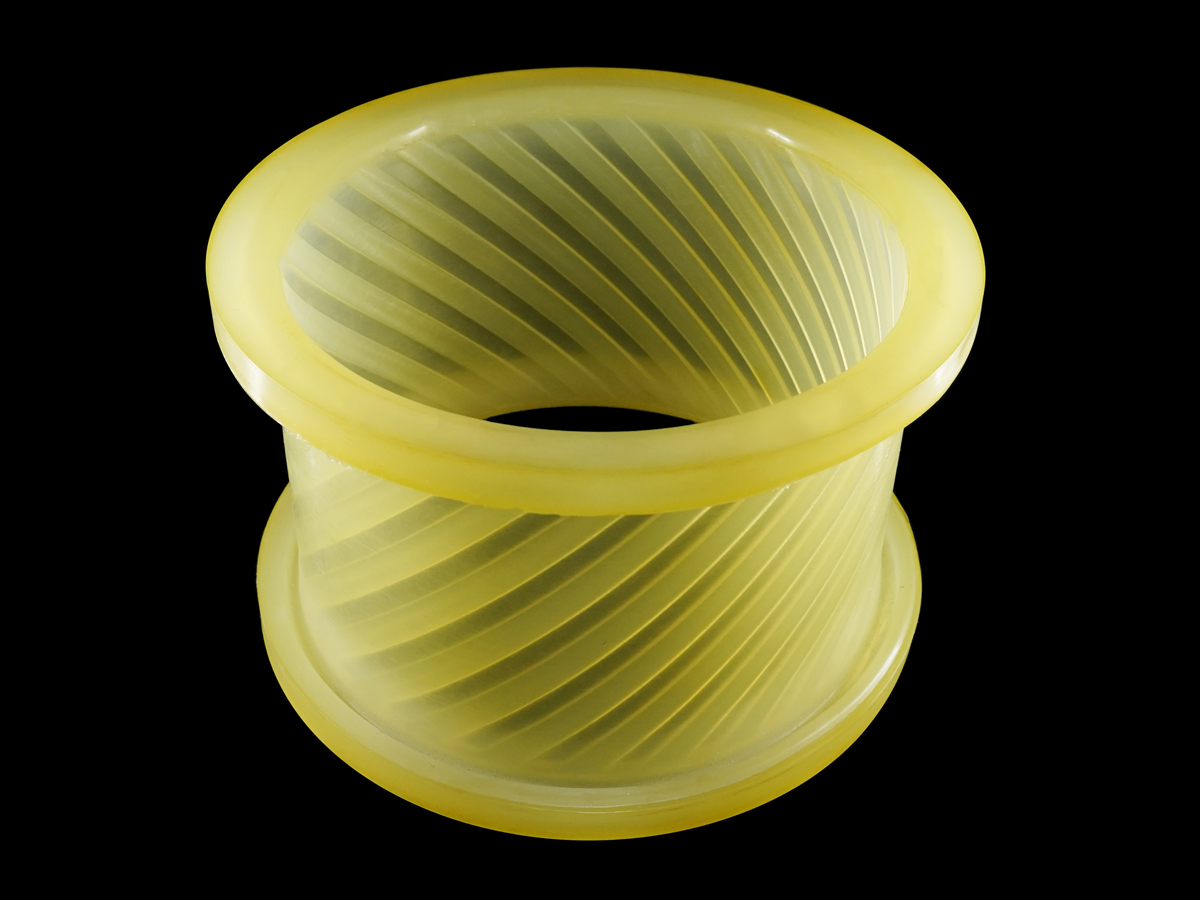

Extrusion molding is suitable for making long or continuous PU products with uniform cross-sections, such as tubes, rods, sheets, films, and fibers. It can also produce products with different colors and textures by using different dies or additives.

However, extrusion molding has some limitations in terms of product complexity, dimensional accuracy, and surface quality.

FacFox’s PU Manufacturing Services

If you are looking for high-quality and cost-effective PU manufacturing services, look no further than FacFox. FacFox is a leading online platform that offers on-demand manufacturing solutions for various industries.

FacFox can help you design, prototype, and produce your custom PU products using advanced molding techniques and equipment. Whether you need small or large quantities of PU products, FacFox can deliver them to you in a timely and professional manner. You can also choose from a wide range of materials, colors, finishes, and post-processing options to suit your needs and preferences.

To get started with your PU manufacturing project with FacFox, simply upload your 3D model or 2D drawing on their website and get an instant quote. You can also contact their customer service team for any questions or assistance. FacFox is committed to providing you with the best PU manufacturing services possible.