What is the span structure of a 3D model?

Span is the distance between two intermediate supports for a structure, e.g. a beam or a bridge. In the field of 3D printing, the span is a horizontal overhang bridge used to connect two ends of the model.

Shall we design a supporting structure for the span?

Not all spans need to be supported. If the span of the bridge is small, the 3D printer can print it out smoothly, and no support structure is needed.

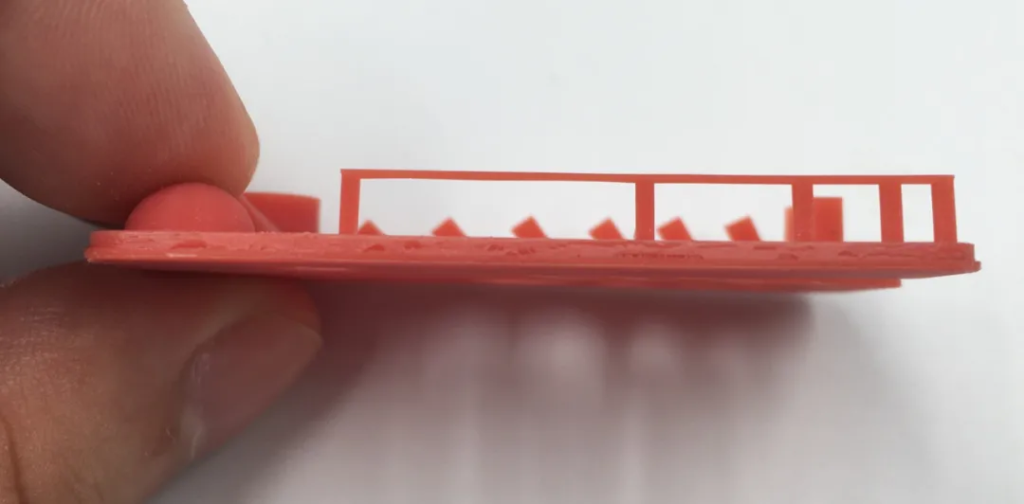

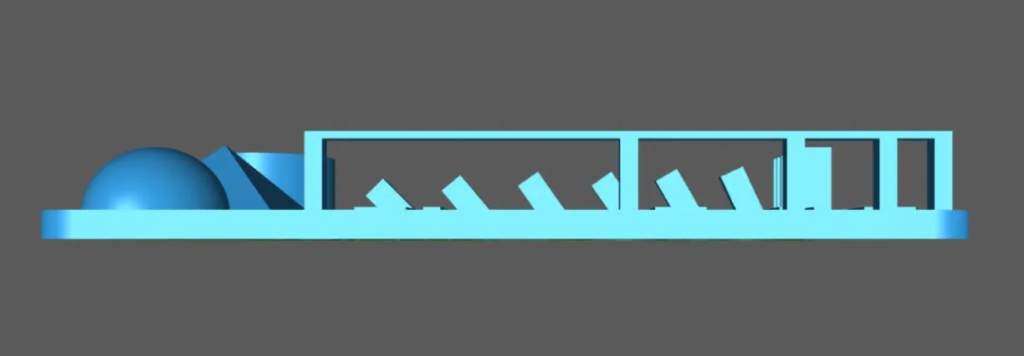

However, if the span is too long, in the case of no support or insufficient support, the layer may be broken as shown in the figure. Even if the first layer of the span is printed successfully, a rupture could also happen when printing the subsequent layers.

In this case, there is a breakage as the unsupported span is too long.

The span is shorter but also has an obvious defect of delamination.

What determines the length of a span?

How long can we print an unsupported span heavily depends on the printer performance and photosensitive resin we use. To be specific, you’d better taken the below factors into consideration.

Poor performance of the 3D printer:

- The Z-axis is unstable;

- The attenuation of the light source;

- Weakened release ability of release film;

- ……

Poor choice of the photosensitive resin:

- The rigidity of the material is not strong enough;

- ……

Our suggestion

Before printing something seriously, let’s test out the longest unsupported span with your resin and 3D printer. Then you can decide whether to add the supporting structure depending on the circumstances.