In the bottom-up SLA printing process, the resin is cured through a window at the bottom of the vat by a light source from below. The build platform is raised out of the resin vat and a “peel” step is required between each layer in order to detach the cured material from the bottom of the vat. This “peel” step is by far the slowest part of SLA printing with most modern light sources.

The separation of the support from the model is a very common printing problem. Not only the green-hands but also some experienced players may encounter this condition. As long as the model is separated from the supporting structure in the printing process, the failure is doomed.

It happens when the pulling force between the bottom of the vat and the newly cured material is too large in the “peel” step. To solve this problem, we have to make the cured material detached from the bottom successfully. Here are a few aspects you can check to find the reason.

Exposure

Short exposure time will lead to insufficient curing of the model, resulting that the support or some layers being too soft. During the “peel” process, the support and the model will be separated under a large pulling force.

The supporting structure

If the model is large while the supporting structure is too thin, the support is not strong enough to lift the model, and the breakage happens.

How deep does the support penetrate into the model?

The deeper the top penetrates into the model, the closer the support head is inserted into it, and the larger the contact area between the support head and the model. That’s why we need to ensure that the depth of penetration is sufficient to lift the model from the vat.

At the same time, it should also be noted that deeper depth will cause more obvious marks when the support is removed.

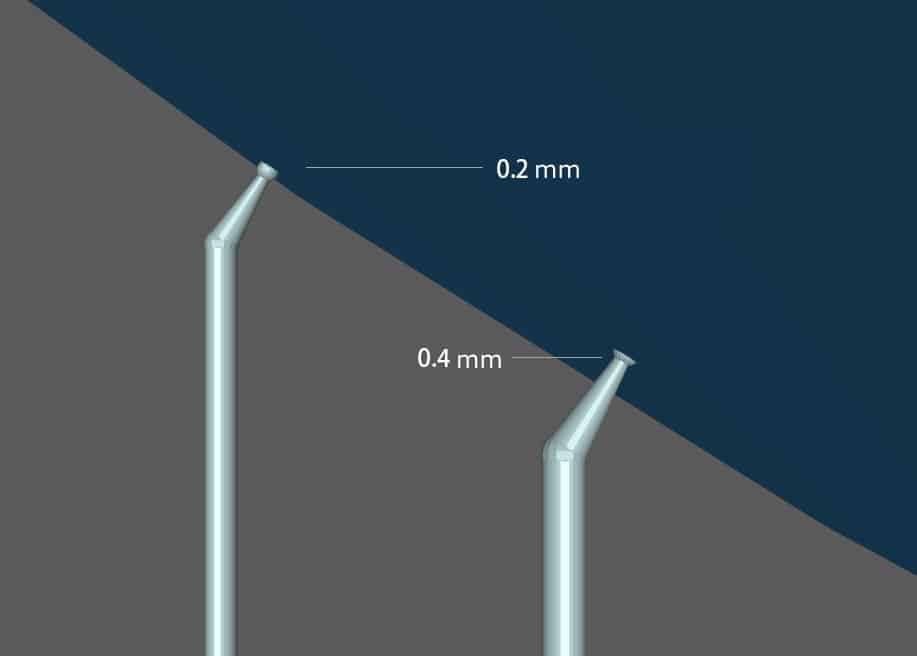

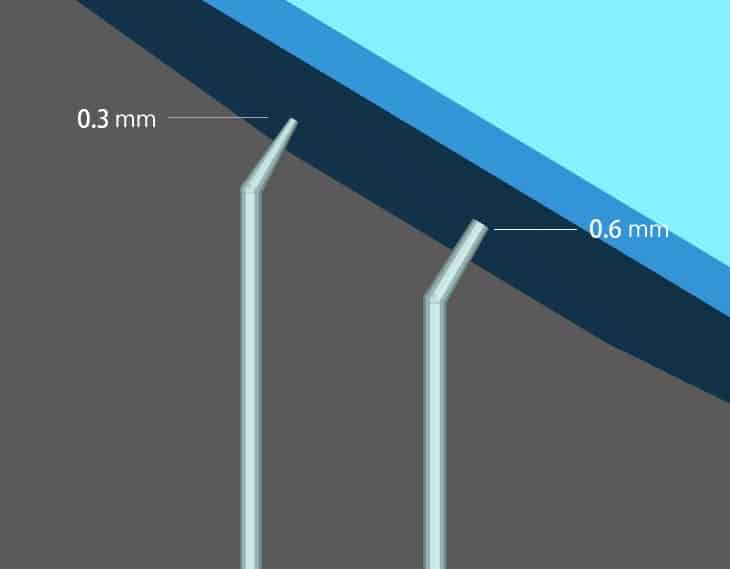

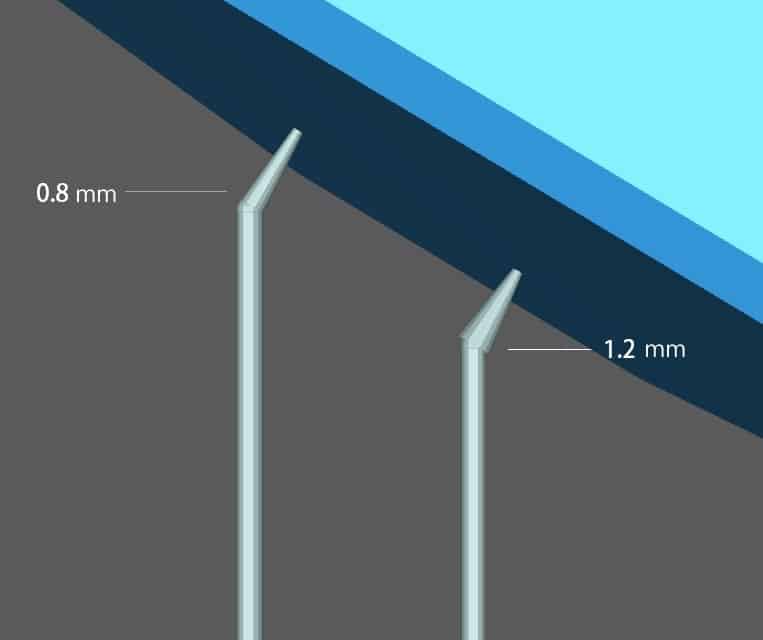

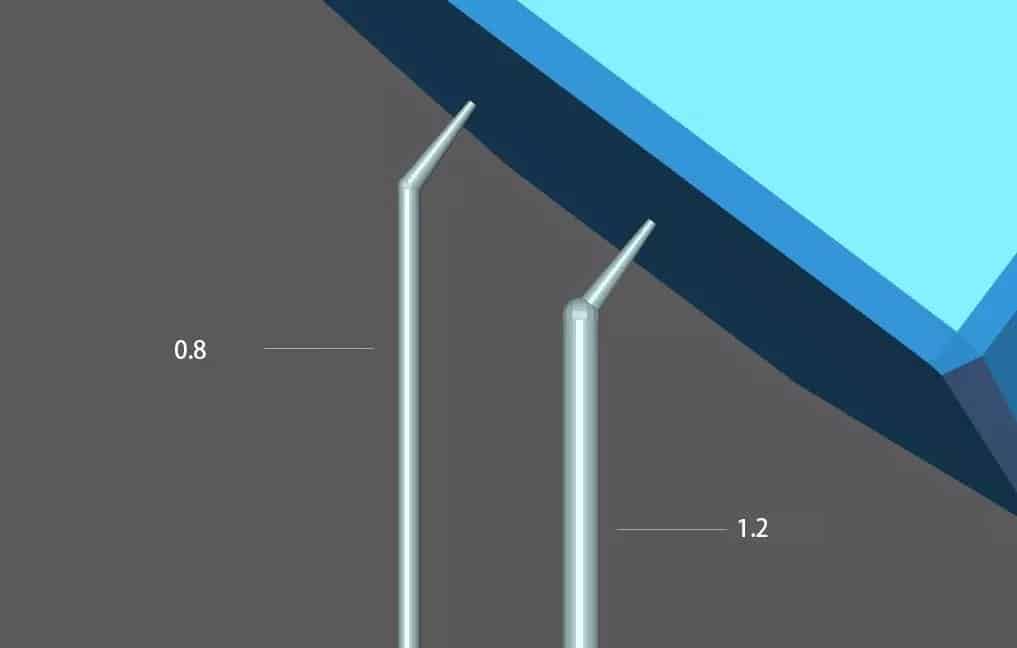

How large is the diameter of the support?

The upper/lower ends are like the “joint” of the support. If the joints are not well connected, they are easy to “fracture”.

Generally, the larger the diameter of the ends is, the higher the strength of the support can offer. Properly adjusting the diameter of the upper/lower ends can help to stabilize the support.

The middle part of the support acts like the “spine”. The thicker the middle part is, the stronger the support can be. Obviously, the “spine” can easily be broken when it’s too thin.

Please also note that the overall ratio of the supporting structure should be balanced. That is to say, the parameters of the ends and the middle part are better to be similar.

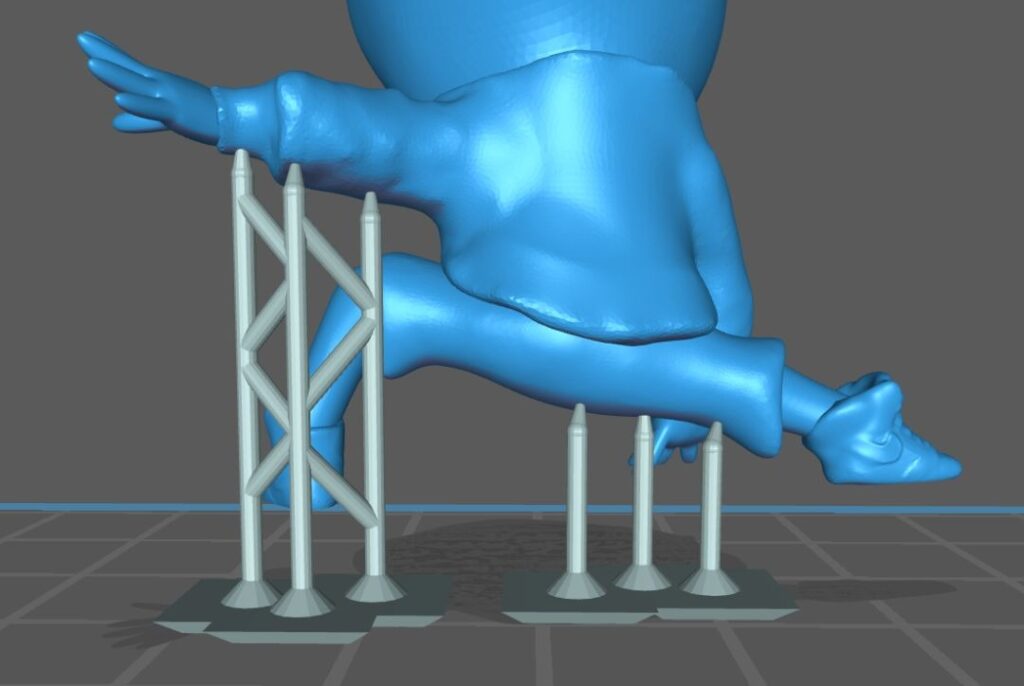

The design of the supports

Among different designs of supporting structure, cross-linking support can greatly reduce the probability of deformation. This design makes the supports more strongly connected and not easy to break. Even if some parts are missing or broken, other cross-linked parts can continuously play the role, greatly improving the success rate of printing.

Lifting speed

It’s the speed of the moving platform. According to common sense, the swifter the cured material lift, the stronger the pulling force is. When the lifting speed is set too high, the “peel” process will be hard.

The release film

When the release film contacts with a specific material under general conditions, it is not sticky or slightly sticky so that the model can be attached to the forming platform and separated from the release film.

But if the release film is worn, too loose, or too tight, it will affect the pulling force and drag the model from the supporting structure or the forming platform.

The resin material

The characteristics of the resin material also have an impact. If its viscosity is too high, the pulling force will increase and the support will be separated from the model.

Imagine, pulling objects out of water and swamps, the latter one will need more efforts as the swamps are more viscous.

In addition, if the lifting speed is too high, the support may be dislocated, fractured and separated from the model.

The model

The processing of the model itself, such as improper placement angle, hollowing-out, punching, etc., can all cause excessive pulling force, which may also make the support separate from the model.

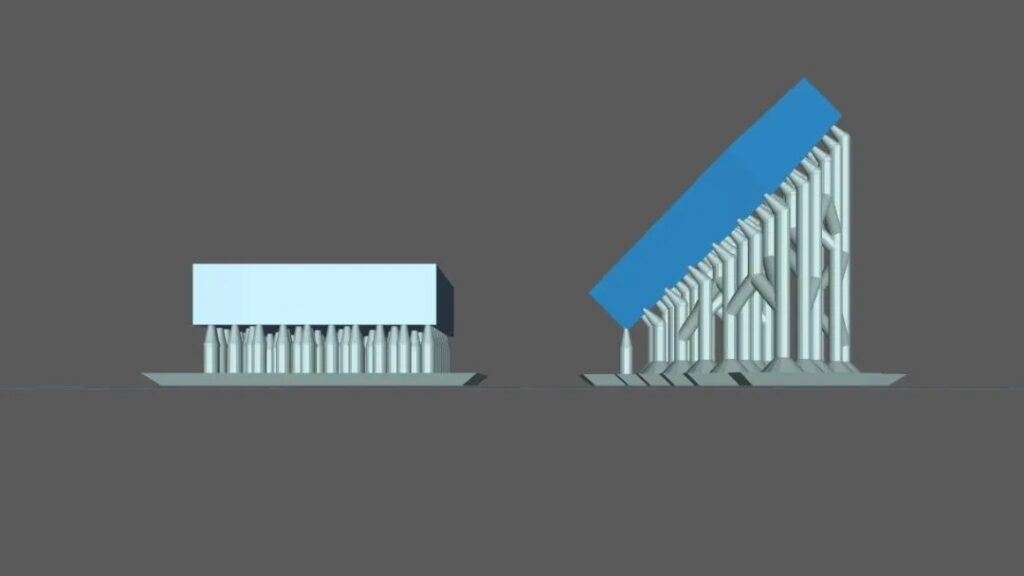

The placement of the model

As shown in the figure, when placement is different, the contact area of the model and the release film is also different. The larger the contact area, the greater the pulling force is. Therefore, the block on the left is more likely to separate from its support.

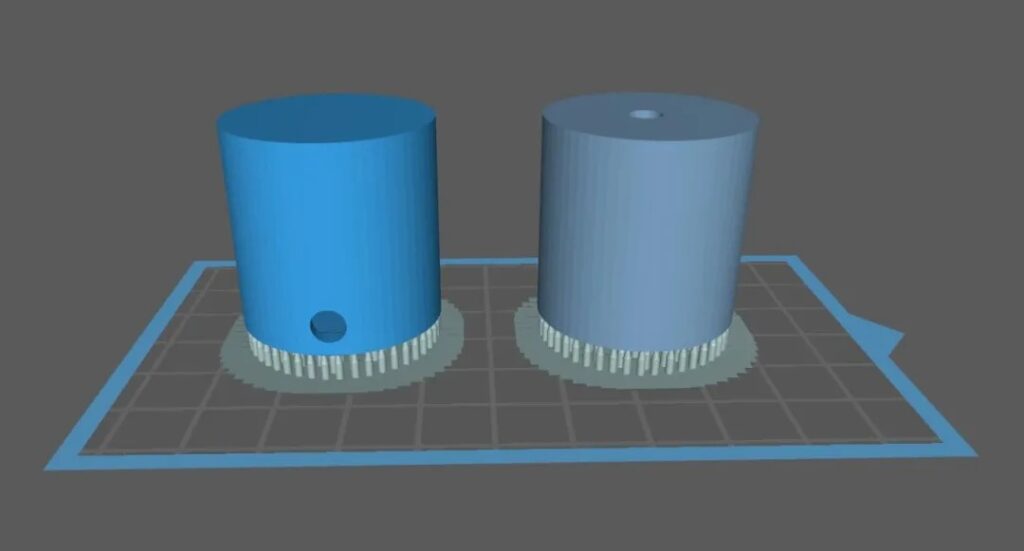

The drilling position of the model

The drilling position also matters. As shown in the below figure, the left one is drilled on the lower part, so the hollowed model is not sealed and the “peel” process is easy. As for the right one, the drilling position is on the top side, making pouring excess resin convenient, but it most likely cause the separation as the inner pressure is large in the sealed model.

In addition, the different punching positions of the hollow model will cause the problem of sealing and drawing of the model. As shown in the figure below, the left side of the hollow cylindrical punching position is at the lower end, which can solve the sealing problem well. The right side of the hollow cylindrical punching position is at the upper end. Although it is convenient to drain after printing, the entire printing process is in a sealed environment. The pull-out force/release force during seal pull-out is very large, which can easily cause the support to separate from the model.

3D printer

The light sources and LCD screens of the 3D printer may also cause the support to be separated from the model.