Through impressive, metal 3D printers come at a price. Find out how much a metal 3D printer costs by looking at some popular machines on the market.

Metal 3D printing has been a hot topic for a while now, and that’s no surprise given the technology’s incredible potential. Yet, despite the industry’s growth, prices of printers seem to be a bit of an unknown.

Manufacturers of metal 3D printers don’t usually list prices online, and nor can the values be easily “Googled”. The main reason for this is that manufacturers usually tailor quotes specifically to clients’ needs. Indeed, a metal 3D printer can’t simply be ordered online like your typical FDM 3D printer; chances are you’ll need to arrange multiple calls, emails, and meetings.

As you can generally infer when a price isn’t listed online, metal 3D printers are expensive. Prices for professional machines range from around $50,000 to $1 million. That’s a very wide range, and the final amount is highly dependent on a printer’s size and performance.

Cost Is More than Price

It’s important to keep in mind that the price of the machine itself often represents only a fraction of the overall cost of metal 3D printing. In some cases, the printer’s price may account for less than half of all related expenses. Additional costs include operation, maintenance, material, and post-processing costs. In terms of the cost of materials, though not all metal 3D printers use metal powder, a kilogram of this material alone can cost between $300 and $600.

Similarly, post-processing requirements depend on which technology you use. For example, a station for debinding and sintering is required for metal binder jetting. Powder bed fusion doesn’t require the same add-ons, but as supports are needed, the specific tooling used in post-processing can also become expensive.

It’s also important to consider that metal 3D printers aren’t plug-and-play machines. The staff and training costs to operate these machines are an important operating cost to factor in. To sum up, it’s all big numbers with metal 3D printing.

Alternatively, it’s possible to produce real metal parts on an FDM machine. However, not every printer is capable of working with these types of filaments, and the post-processing is just as demanding as for other metal printing technologies.

In this article, we’ll present a few of the market’s most popular metal 3D printers and their prices, moving from low to high. Where relevant, we’ll also highlight secondary costs like machine add-ons.

Before that, though, we’ll discuss how it’s possible to have something metal 3D printed without having to invest in the necessary equipment, material, and training. Let’s dive in!

Metal 3D Printing Services

Based on the price tags you’ll soon be reading about, metal 3D printing isn’t cheap. These machines are serious devices requiring serious skills to operate. Not only that, metal 3D printers are massive, meaning they require a lot of space.

Companies that purchase metal 3D printers either use them on a daily basis or simply have the funds to afford such machines to produce small batches of custom parts. But what if you simply want to try metal 3D printing or need just a few small items made in metal? That’s where 3D printing services come in.

Through Craftcloud by All3DP, not only are you guaranteed to find the best price and provider for your needs, you also stand to benefit from the full catalog of available materials and finishes.

Now, on to the printers.

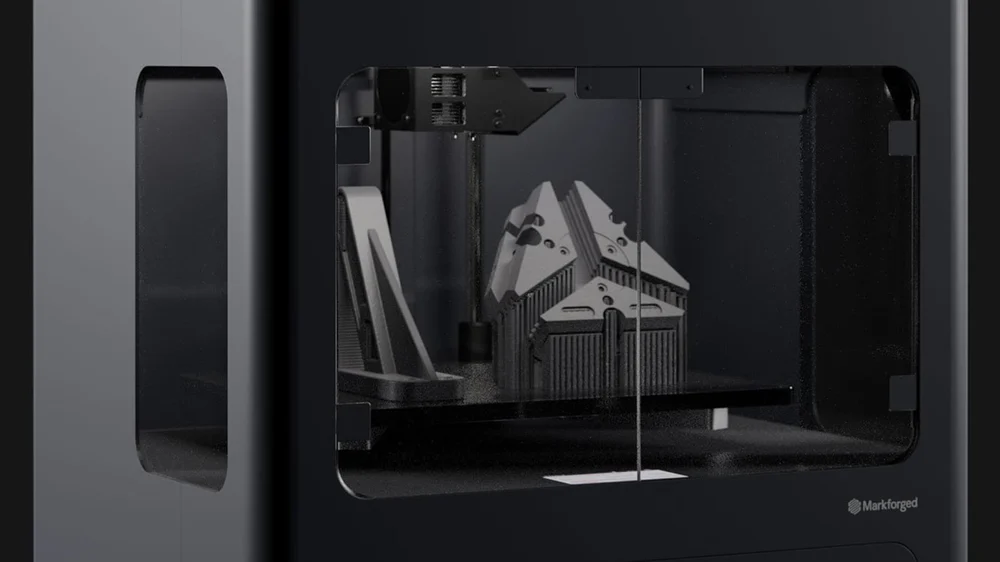

Markforged Metal X – $99,500

The Metal X from Markforged is the company’s first metal 3D printer, designed with the goal of making metal 3D printing more affordable. Normally, the terms “affordable” and “metal 3D printing” don’t make much sense together, but Markforged has somehow made it possible.

The Metal X is priced just shy of six figures – $99,500, to be precise. That’s not bad at all, especially considering the relatively large build volume of 300 x 220 x 180 mm.

The Metal X works in a way similar to FDM technology. It produces metal parts by extruding metal powder bound in a plastic matrix. Markforged likes to call this technique atomic diffusion additive manufacturing, or ADAM.

Unfortunately, the printer alone isn’t enough to complete the production of a metal part. Two post-processing units are needed: the Wash-1 and the Sinter-1. And while we don’t know the exact prices of these devices, some sources claim a price tag of around $165,000 for all three units together.

- Technology: Atomic diffusion additive manufacturing (ADAM)

- Build volume: 300 x 220 x 180 mm

- Price: $99,500

Arcam Spectra H – $100,000-$250,000

Arcam is a Swedish company and one of only a few producing electron beam melting (EBM) 3D printers. GE Additive, General Electric’s additive manufacturing firm, is the majority owner of Arcam.

Arcam’s Spectra H is an industrial metal 3D printer developed mainly for the aerospace industry. The price for the Spectra H is not listed on the official website, but it’s estimated to be between $100,000 and $250,000.

The printer utilizes EBM to achieve highly accurate, lightweight metal parts. For this technology, the Spectra H’s build chamber is one of the largest, measuring 250 mm in diameter and 430 mm in height.

After printing on the Spectra H, the entire build tank (barrel) is removed and transferred to the post-processing unit. This consists of a powder recovery system where parts are cleaned with compressed air, but also a newly developed particle removal system (PRS) that uses a magnetic separator to remove the remaining small powder particles.

After the PRS, the barrel is transferred to an auto-dosing sieve where the powder parts have been through PRS, the powder is again cycled through a magnetic separator to ensure it’s all been properly cleaned.

- Technology: Electron beam melting (EBM)

- Build volume: ⌀250 x 430 mm

- Price: $100,000-$250,000

Desktop Metal Studio System 2 – $110,000

Desktop Metal Studio System 2 is the second generation of the firm’s popular solution for accessible metal 3D printing. This new second generation follows and improves upon the very same ethos associated with the first generation, which is office-friendly metal 3D printing.

Whereas operating the first generation Studio System included a solvent debinding phase, the Studio System 2 removes this step entirely. This creates several benefits. Firstly, there are no more chemical odors present. Also, the price per part gets reduced, since there is one step less involved in the printing process.

The result of such a change in the workflow is a much simpler one, now consisting of only two phases: printing and sintering. Therefore, the Studio printer is not complete without a furnace used for sintering, which adds to the overall price.

Desktop Metal claims the Studio System 2 can deliver even more precisely made parts thanks to the redesigned print heads, as well as the heated build chamber.

Overall, the Studio System 2 is a rather brilliant solution for metal 3D printing in an office environment. The components of the whole system don’t take a huge amount of space, and the overall price isn’t too bad, either.

- Technology: Bound metal deposition (BMD)

- Build volume: 300 x 200 x 200 mm

- Price: $110,000

Desktop Metal Shop System – $150,000-$225,000

The Desktop Metal Shop System is a binder-jetting metal 3D printing solution tailored specifically for machine shops.

The nature of the binder jetting 3D printing technology allows for faster print times when compared to laser metal 3D printers. This is very important for machine shops who need to produce a certain amount of parts per day.

The Shop System also comes with an interesting feature that is variable build volumes. The range consists of 4-L, 8-L, 12-L, and 16-L build volume configurations. Pricing starts at $150,000 for the 4-L configuration and peaks at $225K for the 16-L version.

Unfortunately, the price doesn’t stop there. Alongside the printer, a depowdering station is needed as well as a furnace, which add up to the overall cost of the entire system. The depowdering station will set you back circa a further $15,000, while the furnace is more expensive, coming in at roughly $85,000.

With the print speed provided by binder jetting technology, as well as the adjustable build volumes, the Shop System is truly a great solution for machine shops printing batches of parts on a daily basis.

- Technology: Binder jetting

- Build volume: Switchable between 4-L, 8-L, 12-L, and 16-L configurations

- Price: $150,000 (4L version) – $225,000 (16L version)

Trumpf TruPrint 1000 – $170,000

The Trumpf TruPrint 1000 LMF is an industrial metal 3D printer based on laser metal fusion (LMF) technology, which is the same thing as selective laser melting (SLM).

The build chamber of the TruPrint 1000 isn’t very large, coming in at 100 x 100 x 100 mm. Nevertheless, it’s reported by 3D-grenzenlos to have a starting price of $170,000. This number is hard to confirm, but we figure $300,000 is a safe upper bound.

Apart from the cost of powder, additional investments for this machine would include post-processing methods like sanding and polishing.

- Technology: Selective laser melting (SLM)

- Build volume: 100 x 100 x 100 mm

- Price: >$170,000

EOS M 100 – $350,000

The M 100 is EOS’s entry-level metal 3D printer. Powered by direct metal laser sintering (DMLS), it has a reputation for being a high-quality machine, ideal for cost-effective small production runs.

The most common use case of the M 100 is 3D printing small batches of implants and other medical accessories. Part of the reason for that is the relatively small build chamber, which measures 100 mm in diameter and 95 mm in height.

According to Business.com, the M 100 goes for $350,000, but that figure likely doesn’t include any add-ons. In terms of post-processing, EOS sells shot peening stations and furnaces that finish the sintering of parts.

- Technology: Direct metal laser sintering (DMLS)

- Build volume: ⌀100 x 95 mm

- Price: ~$350,000

HP Metal Jet – $400,000

One of the recent newcomers to the world of metal 3D printing was none other than HP. Their Metal Jet 3D printer makes use of binder jetting to fuse metal particles. HP’s goal with the Metal Jet was to deliver a machine that enables cost-effective high-volume production.

The Metal Jet comes with a build volume of of 430 x 320 x 200 mm, which is a massive upside of HP’s offering. The system is priced just under $400,000, making it a very desirable choice in the ever-growing market of metal additive manufacturing.

Apart from material and maintenance costs, a machine such as the Metal Jet would also require a sintering furnace. As with other add-ons mentioned in this article, it’s likely that this unit must be purchased separately.

- Technology: Binder jetting

- Build volume: 430 x 320 x 200 mm

- Price: $400,000

SLM 125 – $400,000-$500,000

The SLM 125 is a compact metal 3D printer that comes with components of higher performance than usually found in its class. It’s the smallest machine in the SLM Solutions lineup, making it ideal for both rapid prototyping and low-volume serial batch production.

Inside the SLM 125 there’s a 400-watt fiber laser which has more power than the lasers of other similarly sized machines and cuts powder consumption by up to 80%, the manufacturer claims.

Although the build volume isn’t massive, it can be called sufficient for one-off parts and prototypes. Workshops, institutes and other ventures looking for a powerful metal 3D printer capable of working with a wide variety of metals should consider the SLM 125 since it offers a nice balance of performance, pricing, and production capacity.

- Technology: Selective laser melting (SLM)

- Build volume: 125 x 125 x 125 mm

- Price: $400K – $500K

3D Systems DMP Flex 350 – >$575,000

Back at the end of 2018 3D Systems announced the DMP Flex 350 as a new addition to its metal 3D printers lineup. The DMP Flex 350 succeeded the DMP 320, bringing a handful of new improvements.

One of the most important advancements associated with the Flex 350 is the improved gas flow technology. In case you don’t know, the whole point of the gas flow technology is to evacuate oxygen from the build chamber. Argon gas is usually used for this.

The consumption of argon gas has been reduced significantly, while oxygen purity stats have improved. This ensures better repeatability and better print quality as parts can now be denser. The improvements in gas flow are also beneficial for the reuse of the powder.

The DMP 350 has a reasonably sized build volume of 275 x 275 x 420 mm that acts like a vacuum chamber. As the official site claims, it’s a 3D printer intended for heavy usage, meaning it’ll be capable of running 24/7 on the factory floor.

Paired with a large selection of ready-to-run metal alloys including aluminium, steel, inconel, titanium, and cobalt chrome, it’s a serious solution for manufacturing metal parts whose strength can be compared with forged parts.

- Technology: Direct metal printing (DMP)

- Build volume: 275 x 275 x 420 mm

- Price: >$575,000

Desktop Metal Production Printer – $750,000

Desktop Metal specializes in industrial additive manufacturing solutions, with the Production System at the peak. What makes the Production System so unique is its Single Pass Jetting technology. It enables much faster production speed when compared to other metal 3D printers.

Nozzles for the binder agent work together with powder spreaders to print in a single pass across the build area. The idea behind the technology is to ensure that, with each motion, printing is happening, and that’s what enables the high-speed production.

Good things aside, the $750,000 price tag “only” gets you the printer, and not the necessary furnace. The furnace is used to heat the printed parts to just below their melting temperature to remove the remaining binder and completely sinter the powder, thus achieving the desired density of the parts. This unit is similarly rather expensive, with prices starting at $500,000.

- Technology: Single pass jetting (binder jetting)

- Build volume: 337 x 337 x 330 mm

- Price: $750,000