Desktop 3D printing has undergone somewhat of a revolution in the last decade. The technology, which began with the consumer market in mind, has become an important part of the industrial, professional market. By enabling cheaper and faster production, desktop 3D printers are increasingly becoming a vital part of the industrial landscape.

But what has fueled this transition and what does it mean for the present and the future of desktop 3D printing and 3D printing as a whole?

RepRap: democratising 3D printing through desktop

In 2018, the 3D printing industry celebrated the 10th anniversary of the RepRap project — a project that would prove instrumental for the evolution of desktop 3D printing.

RepRap, short for replicating rapid prototyper, began with the idea of making a low-cost desktop 3D printer that could print many of its own components. The goal of the project was ambitious: to get these desktop 3D printers in as many peoples’ hands as possible.

The open-source project, led by Dr Adrian Bowyer from the University of Bath, saw tremendous success in the Do-It-Yourself (DIY) community. But for desktop 3D printing, its implications were much deeper.

With the RepRap movement well underway from 2008, a new crop of low-cost desktop 3D printer manufacturers had emerged. For example, MakerBot, founded in 2009, emerged as one of the companies driving the vision of transforming production through 3D printing.

Building on the success of the RepRap movement, MakerBot began by producing open-source DIY kits for consumers wanting to build their own 3D printers and 3D-printed products.

The release of MakerBot’s most recognised 3D printer, the Replicator 2, in 2012 coincided with the height of the consumer 3D printing bubble. With the general industry perspective betting on desktop 3D printers finding their way into mainstream households, Makerbot hoped to spark a new era of consumer 3D printing.

As we know, the 3D printing revolution never materialised — at least not in the consumer market.

A key obstacle for mass consumer adoption was the level of complexity needed to operate a machine. Coupled with limited material choices and a need for design skills, 3D printers were not, and still have yet to become, a consumer-friendly product.

The struggle to establish a consumer market has forced a number of desktop 3D printer manufacturers out of business. However, a few have survived — and thrived — by transitioning from the consumer to the professional and enterprise market.

From consumer to industrial

While desktop 3D printing has yet to find its niche within the consumer market, the technology has become an important part of the industrial manufacturing landscape.

The desktop 3D printing segment has experienced an exponential rise in the last decade. An estimated 1,816 systems were sold in 2009 (Wohlers Report 2015), a figure that surged to over 500,000 units in 2017 (Wohlers Report 2018).

The demand for industrial systems that are smaller and a fraction of the cost of their larger counterparts is a key factor behind the rise of desktop 3D printing for industrial applications.

Today’s desktop 3D printers have a wide range of uses in the professional environment, offering an affordable tool for rapid prototyping, tooling and end-part production.

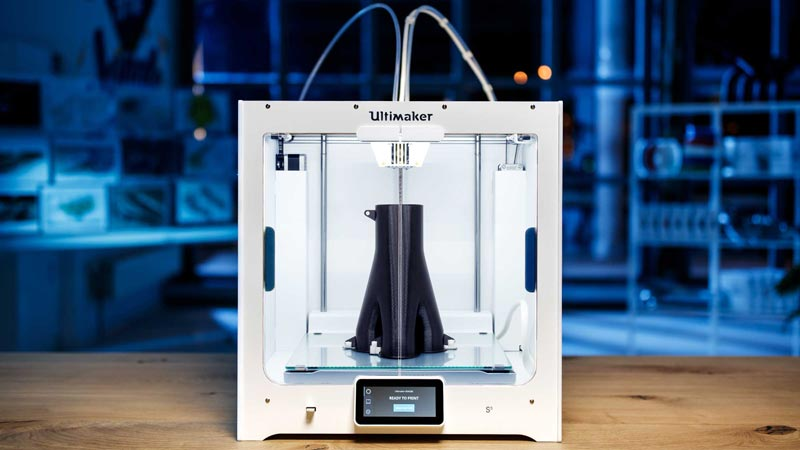

Ultimaker: from DIY kits to factory floor solutions

Perhaps one of the most prominent examples of a company that has successfully made the leap from consumer to industrial 3D printing is FFF 3D printer manufacturer, Ultimaker.

“Ultimaker never really bought into the whole consumer hype that happened between 2012 and 2013,” says John Kawola, Ultimaker’s North America President, in an interview with AMFG.

“We always saw a real difference in the consumer market, where the people who were already pretty hardcore makers or hobbyists would already have the necessary equipment at home. And we thought that was a good market for 3D printing. The general hype extended to thinking that everybody would have a 3D printer – I think that’s turned out not to be true, at least not then and probably still to the present day.”

Founded in 2011, Ultimaker has gone from manufacturing DIY kits to producing industrial desktop systems that have been adopted by the likes of Volkswagen Autoeuropa and Jabil.

Ultimaker’s first machine, the Ultimaker Original, was developed in 2011 and distributed as a kit to the maker community. The machine could print objects up to 21 x 21 x 20.5 cm at a resolution of 20 microns. While sufficient for hobbyists, the machine lacked the speed, quality and material selection required for industrial applications.

In the years since, Ultimaker has made strategic moves to develop desktop solutions suitable for industrial applications.

In 2013, the company released Ultimaker 2, which evolved to the larger Ultimaker 2+ system. A year later, the company took its technology another step towards the professional market with the launch of the Ultimaker 3 machine.

Compared to Ultimaker 2, the third model boasts a build volume that is 10 cm higher, as well as new dual extrusion capabilities not available with its older systems.

Dual extrusion is particularly beneficial because it allows users to print with two materials, for example with a standard material and a dissolvable support material, or two materials in different colours.

In 2018, the company released its latest desktop 3D printer: the Ultimaker S5.

The dual-extrusion Ultimaker S5 has a bigger build volume of 33 x 24 x 30 cm compared to the Ultimaker 3’s 21.5 x 21.5 x 30.0 cm and can reach printing temperatures of up to 280˚C. This makes it particularly suitable for high-temperature engineering materials like PC and nylon.

Use case: Heineken

Heineken, one of the world’s largest brewing companies, has been using Ultimaker’s S5 printers at its brewery in Spain to produce a range of custom tools and spare parts.

Having adopted desktop 3D printing, Heineken has reported cost reductions of 70-90% with the technology, contrasted with traditionally manufactured parts and tools. It has also seen considerable increases to production uptime.

The company can also optimise the designs of its machine components using 3D printing. For example, the team redesigned and 3D printed a metal part used with a quality sensor on a conveyor belt, which previously would frequently knock bottles over.

Heineken’s example illustrates just how much desktop 3D printers have evolved to enable a multitude of applications on the factory floor.

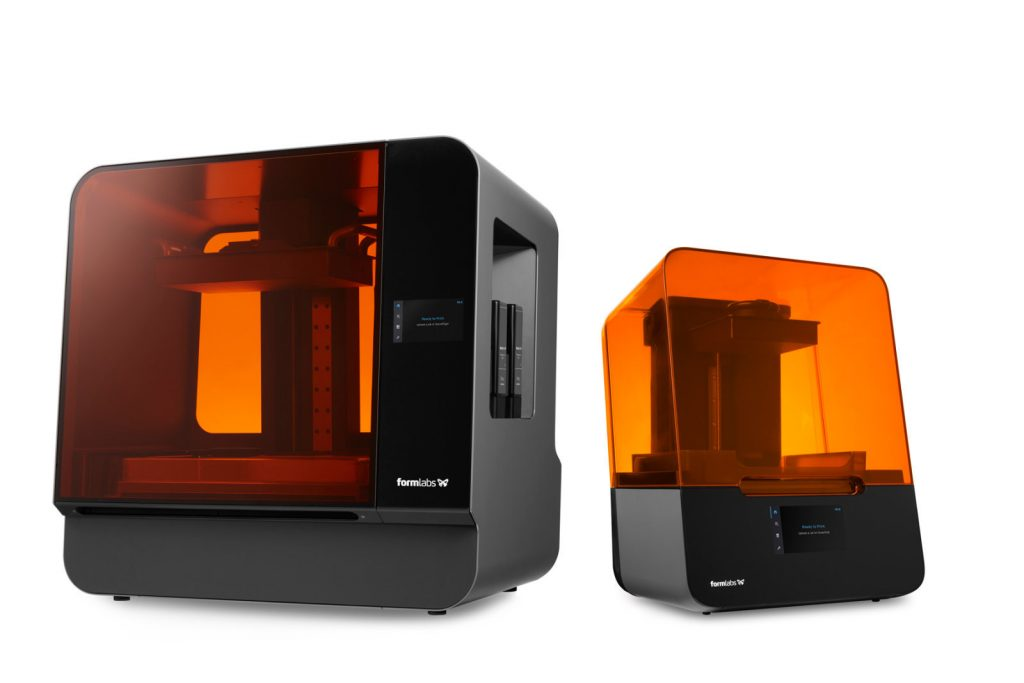

Formlabs: Bringing SLA to desktop

Like desktop FFF 3D printing, adoption of desktop Stereolithography (SLA) systems has taken off in the last few years.

As was the case with FFF 3D printing, the expiration of several SLA patents at the end of the 2000s was a catalyst behind the rise of desktop SLA 3D printing. One company to take advantage of this shifting landscape was Formlabs.

Founded in 2012, Formlabs released its first desktop SLA machine, Form 1, in the same year. Targeting professional users from the outset, the company raised nearly $3 million on Kickstarter in a bid to bring ‘the power and resolution of a truly professional machine’ to desktop.

At the time, the market for SLA machines was dominated by larger and more expensive industrial 3D printers, inaccessible to the majority of smaller companies.

With the introduction of the Form came the desire to change this status quo and make SLA more affordable and accessible.

One of the key milestones in this regard has been the release of Formlabs’ Form 2 machine. The Form 2 features a build volume of 14.5 × 14.5 × 17.5 cm and a powerful optical engine, enabling high quality, reliable prints.

However, anyone familiar with 3D printing knows that the printing process is only one part of the workflow. In SLA, post-processing operations like washing and curing are necessary to achieve high-quality results, but are often done manually.

Formlabs understood that to further expand its solutions into the professional market, it would need to make the processes as streamlined as possible.

With this is mind, Formlabs released Form Wash and Form Cure post-processing accessories for the Form 2. The wash and cure stations help clean up and cure prints, automating some of the manual post-processing steps.

To meet the growing trend of automated 3D printing, the company demonstrated the Form Cell platform for scalable 3D printed production in 2017. The solution comprises an enclosure containing five Form 2 3D printers and a Form Wash and Form Cure module, managed by a moving robotic gantry.

Use case: Northwell Health

Northwell Health, New York State’s largest health care provider, has been one of the early users of Form Cell, using the machine to produce patient-specific anatomical models and surgical guides.

By using 3D-printed, personalised anatomical models, surgeons at Northwell Health can prepare for difficult surgeries more effectively and reduce time spent in the operating room. The latter, according to Northwell Health’s estimations, could translate into up to $1,750,000 in annual savings, thanks to the operating room cost avoidance.

Bringing SLA to desktop and continuously improving on the technology has helped Formlabs to cement its position in the industrial market. The company is reported to be the world’s largest seller of SLA 3D printers, with more than 40,000 systems sold.

Spotting an opportunity to move into other technologies, Formlabs also announced its first powder-based desktop SLS system, the Fuse 1, in 2017. This, coupled with the latest line of its SLA 3D printers introduced earlier this year — the Form 3 and the large-format Form 3L — Formlabs looks set to maintain its status as one of the leading manufacturers of professional desktop 3D printers.

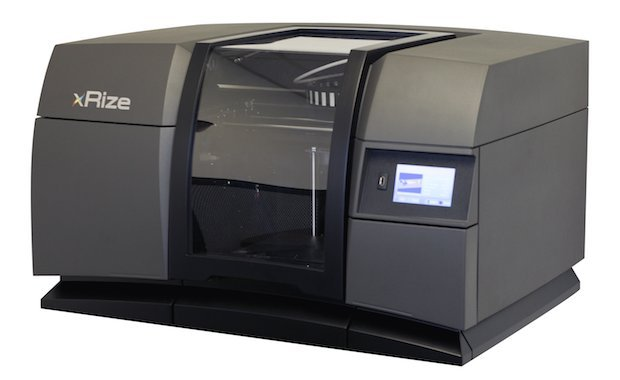

RIZE: Making desktop 3D printing sustainable

Fitting an industrial machine into a desktop format brings a lot of benefits but is just one part of the equation, according to hardware manufacturer RIZE. To help industrial desktop 3D printing to truly take off, it needs to become simpler and safer to use.

“We set ourselves the goal of simplifying the user experience to make it easy and safe, and thereby allow any user to use industrial 3D printing,” said Andy Kalambi, CEO of RIZE, in a recent interview with AMFG.

“We believe that with that kind of an approach, 3D printing can become a tool used by a lot of different stakeholders within an organisation.”

Starting with the RIZE One 3D printer, the company has developed a unique 3D printing process called Augmented Deposition. The process combines the principles of FFF technology and material jetting to mark 3D-printed parts with text or graphics. More recently, the manufacturer released its full-colour XRIZE 3D printer.

To simplify the 3D printing process, RIZE’s 3D printers jet a special Release Ink between the part and the automatically-generated support structures. This enables users to quickly peel away the support material once the print is complete.

The machines also use emission-free materials, making the technology completely safe for office use.

By focusing on safety and ease of use, RIZE has made its technology particularly appealing for product development firms looking to simplify and speed up their prototyping process.

For example, Boston Engineering has added RIZE’s machine to its 3D printing capabilities, but instead of placing the 3D printer in their specially-equipped 3D printing lab, the Boston Engineering team operates it from the office. This allows the team to print prototypes in as fast as one day, compared to lead times of 2 to 3 days when manufacturing them in the lab.

Bringing engineering-grade materials to desktop 3D printing

As the technology behind desktop 3D printers continues to evolve for the industrial market, so too has the range of suitable materials. Beyond the standard PLA and ABS, industrial desktop 3D printers are now capable of supporting engineering-grade materials.

This has opened the door to high-performance materials that were previously only available with larger industrial machines. These high-performance materials can be used for a broad range of applications, from functional prototypes to low-cost tools and spare parts.

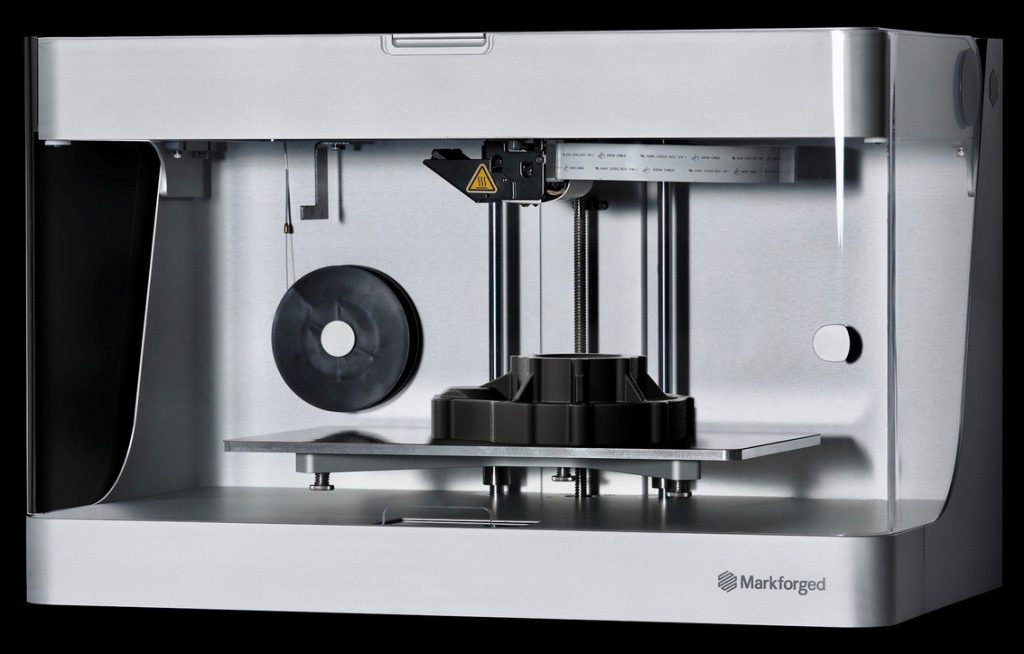

Markforged: Composite polymer 3D printing

One of the key advancements in this area has been the introduction of composite polymer 3D printing.

Polymer composites are typically materials made of two components, a core material and a reinforcing material — for example, fibre. Polymers reinforced with fibre, such as glass, carbon or aramid, create parts with added strength, stiffness and durability.

Markforged is reported to be the first company to bring continuous carbon fibre reinforced 3D printing to desktop. The company launched its first composite 3D printer, Mark One, in 2014, with the ability to 3D print nylon parts reinforced with continuous strands of carbon fibre, fibreglass or Kevlar.

Since then, Markforged has unveiled a number of upgrades, including the Mark Two and Onyx series, as well as the X3, X5 and X7 industrial 3D printers. All of the systems are based on the company’s Continuous Filament Fabrication (CFF) technology.

CFF is an extrusion-based process, where one nozzle deposits continuous strands of carbon fibre, fibreglass or Kevlar while the second nozzle lays down the base material such as nylon.

The introduction of CFF technology has been a turning point in 3D printing, as it has unlocked capabilities not available with traditional desktop extrusion 3D printers. Using composite materials enabled by Markforged’s technology, manufacturers are able to create a composite part that is up to 8 times stronger than ABS and 20% stronger than aluminium.

Siemens Gas & Power is one example of a company using Markforged composite 3D printers to produce custom tooling. In a recent case of a housing tooling, the company 3D printed the custom circular saw housing with the Markforged’s proprietary composite Onyx material. The result is the lead time reduced from three weeks to a few days and over $8,000 saved for just one tool.

By developing new ways to print with carbon fibre, Markforged has significantly extended the capabilities of desktop 3D printing. The company reportedly shipped 2,500 printers in 2018, proving that there are many gaps in manufacturing that industrial desktop 3D printing is helping to bridge.

Moving beyond polymers to metals

Polymer materials have historically been the key desktop 3D printing materials. But this status quo has been disrupted with the introduction of the office-friendly metal systems between 2017 and 2018.

Markforged and Desktop Metal are two companies that have helped to make desktop metal 3D printing possible.

Both Markforged’s Metal X and Desktop Metal’s Studio System are extrusion-based 3D printers that use plastic-encapsulated metal powders to create green parts which are then sintered in a furnace. This approach makes it a much more affordable option compared to traditionally more expensive metal 3D printers. This is largely due to lower operating costs, enabled by cheaper metal injection moulding materials.

Priced at less than $200,000, both Metal X and Studio System have sparked new possibilities in desktop metal 3D printing by making the process less expensive, office-friendly and easier to manage.

For example, tool manufacturing company, Built-Rite, is now able to realise the benefits of 3D printing by using Desktop Metal’s Studio System in-house. With the Studio System, Built-Rite can make quick-turn mould assembly components with a process that is 90% cheaper and 30% faster than using a third-party service provider.

This application not only showcases the suitability of the technology for tooling production, but also indicates that metal desktop 3D printers have the potential to reduce the barriers to entry for businesses that previously couldn’t afford to invest in metal 3D printing technology.

Managing desktop 3D printing fleets

Desktop AM machines are relatively inexpensive and, as we’ve seen, their current capabilities span beyond producing makers’ playthings. That’s why desktop 3D printers are often the first choice when companies are looking to invest in 3D printing, whether it’s for internal RP labs or 3D printing services business.

While handling one desktop 3D printer usually doesn’t pose any challenges, when a business invests in its second, third 3D printer or even more, it soon discovers that the workflow is more complicated than it first seemed.

Increasing your investment in 3D printers is a positive sign of growth, but this growth can also create a whole new set of challenges. Managing a constant stream of emails with 3D printing requests, analysing and repairing 3D files, calculating printing costs, scheduling jobs – there’s great chance that your team is performing these tasks manually, limiting the productivity of your department or business.

While these processes are essential for successful utilisation of 3D printers, they can and should be improved to ensure higher efficiency.

One way to do this is through automation software. There are solutions that can streamline the management side of 3D printing, for example by providing a web-based requests submition portal, powered by instant pricing and quotation features. Automation software packages, like AMFG, can also include automated file conversion and repair tools, to simplify file preparation before printing.

Good 3D printing automation software is also able to integrate with 3D printers to provide real-time machine status updates about in-progress, completed, or failed print jobs.

What’s next for desktop 3D printing?

Desktop 3D printing has made huge strides in the last decade: the technology is improving, and the range of available industrial-grade materials is wider than ever before. As the industry has shifted its focus to professional, industrial applications, so too have desktop 3D printer manufacturers.

This has made it cheaper for businesses to invest in the technology, lowering barriers to adoption and crossing the threshold of affordability, quality and reliability.

The pace of innovation in desktop 3D printing shows no signs of slowing down. Today, new processes and materials are being developed and commercialised, taking desktop 3D printing beyond prototyping to manufacturing. Software advancements in automation, too, make desktop 3D printing easier to manage, simplifying the workflow and providing the foundation for scalability.

Looking ahead, we’ll see desktop 3D printing offering new use cases and opening the door to new industry segments. As desktop machines continuously achieve higher levels of performance, they’ll become a standard tool, from office environments and engineers’ desks to factory floors.