The road to standardization for emerging industries and technologies can be long and arduous. But for an industry to develop a strong market, the need for standardised processes becomes increasingly important.

3D printing has reached this watershed moment: 46 % of companies surveyed by EY expect to apply the technology for end-part production by 2022. Clearly, as the technology continues to shift towards production, the need for standardisation is more acute than ever.

The benefits of standardisation for 3D printing

Standardisation refers to the best practices, regulations and benchmarks that guide industries and organisations. For an emerging, disruptive technology like 3D printing, standards can provide a much-needed foundation to facilitate wider adoption of the technology, especially as the market continues to grow. The benefits for better quality assurance and process consistency is clear.

However, the journey towards greater standardisation for additive manufacturing is not straightforward. The digital origins of additive manufacturing mean that there are additional factors to consider than for traditional manufacturing, from the use of data formats to guidelines for design and production processes.

We see two core benefits of standardisation for 3D printing:

1. Ensuring consistency

Consistently producing parts of high quality and ensuring a repeatable process each time remains one of the current challenges within additive manufacturing.

Additive production consists of a complex network of variables, from raw materials to design optimisation and manufacturing processes, which in turn require interaction between an infrastructure of software and hardware. Each of these stages must be monitored, assessed and controlled to ensure the repeatability and reliability of 3D printed parts, whilst avoiding a costly trial and error approach.

Standardisation can help to define the parameters for each step of AM production, helping to create a consistent process every step of the way. This way, a company can compare the quality of its AM processes against a set of preliminary criteria. This ensures that the desired quality outcome is achieved.

2. Meeting regulatory standards

In highly regulated industries like medical, automotive, aerospace & defence, issues with product certification can also delay wider AM adoption. Parts produced with additive technologies have properties that can be quite different from those achieved with subtractive manufacturing, complicating quality assurance and certification.

Qualification and certification standards open a feasible route to product certification by providing the guidelines against which parts are assessed and qualified.

Challenges for standardisation

While some standards for 3D printing do currently exist, many of the critical standards are still under development. We’ve outlined a few areas where standardisation for 3D printing is needed.

1. Materials

One of the current challenges centres around AM-specific materials, for many of which standards do not exist. Materials for metal additive manufacturing in particular are a key area of focus, particularly as they are used by highly demanding industries like aerospace and medical.

The lack of standardisation for AM-specific materials means, for example, that manufacturers are unable to take stress values. Design and process control data is also very limited due to a lack of 3D printing material specifications, which can affect the way a part is created.

One way to partially deal with this problem is to adopt existing standards, developed for conventional materials, directly for AM materials. However, the extent to which these standards can be applied is still to be determined, as the mechanical behaviour of AM parts can differ significantly from their conventionally made counterparts.

2. Process control

The proprietary nature of AM process variables poses another challenge for standardisation. Many 3D printer manufacturers may be unwilling to share data on process variable optimisation, which affects the properties of a printed part like thermal history, microstructure, and defect formation. Here, collaboration and open platform strategies will be key to addressing this challenge

3. Certification

Finally, developing robust certification approaches is an area of focus in 3D printing standardisation. The current method of quality assurance and verification is testing final parts, which requires additional time and resources. To overcome this issue, the industry needs to develop comprehensive part certification processes which will allow for better real-time quality control.

Making the task more difficult is the fact that certification processes differ according to industry and application. How and when testing is done for certification is an area that will need to be specified by any standardisation process.

Developing a standardised framework for 3D printing

So far, a global consensus on standards for additive manufacturing processes and products has not yet been achieved. However, progress is taking shape, with collaborative efforts being made by standards development organisations (SDO) and other bodies to build a comprehensive set of standards for additive manufacturing.

Standards Development Organisations

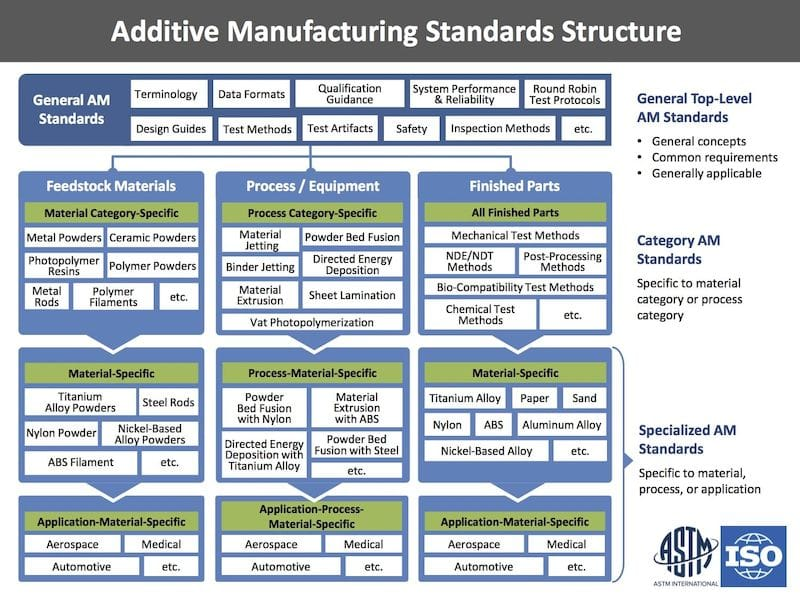

ISO and ASTM International are two key SDOs that have formed dedicated committees to support the adoption of additive manufacturing across industries. Based largely on voluntary efforts, both ISO and ASTM International are working to cover all aspects of additive manufacturing.

In 2016, they set up joint working groups to update and approve a common organisational structure for AM standards, with the goal of harmonising their development within the AM industry.

As part of this collaboration, both SDOs announced a framework for 3D printing standards – the Additive Manufacturing Standards Structure. The framework outlines the various categories that require standardisation, which broadly cover:

- Materials

- Processes and equipment

- The treatment of finished parts

Since then, the collaboration has been fruitful. As of May 2020:

- ASTM Committee F42 on Additive manufacturing technologies has approved 22 standards

- ISO Technical Committee 261 on Additive Manufacturing (ISO/TC 261) has published 15 standards, with an additional 30 standards in various stages of development.

ASTM has also launched several rounds of funding to help support the development of standards for the AM industry. In 2019, a new round of funding was launched, benefitting the same institutions and their research, with the addition of Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC).

3D printing standards for metal powder bed fusion

In 2018, ASTM Committee F42 issued a standard to increase the use of metal Powder Bed Fusion (PBF) processes.

The standard, known as F3303, is geared towards metal additive manufacturing for medical, aerospace, and other sectors. It outlines steps to qualify machines and processes based on SLM, EBM and DMLS technologies. Ensuring that AM steps are fixed and repeatable could help to overcome many of the challenges associated with the application and approval of 3D printed metal parts.

Right now the major focus of ASTM is on developing a standard for SLM technology, currently the most popular metal 3D printing method.

In addition to ASTM, the Metal Powder Industries Federation (MPIF) has recently issued nine MPIF Standard Test Methods for characterising metal AM powders.

Aimed at designers, manufacturers and users of metal AM parts, this collection is yet another sign of industries recognising the growing role of metal 3D printing in the manufacturing world.

Standardising 3D printing for aerospace

To tackle standardisation in metal AM for aerospace, global engineering standards association SAE International has recently issued four new PBF standards.

The new standards suite for Aerospace Material Specifications (AMS) supports the certification of critical aircraft and spacecraft parts, and covers material specifications for nickel alloys and process requirements for 3D printing with metal powders.

However, SAE hasn’t stopped just on that. More recently, the organisation also issued the first AM polymer specifications for the aerospace industry last year. For example, the AMS7100 specification establishes the critical controls and requirements to produce reliable, repeatable, reproducible aerospace parts by Fused Deposition Modeling (FDM®) or other material extrusion production.

ASTM International’s F42 committee is also developing 4 additional standards that will help aircraft parts manufacturers meet safety and performance requirements. The standards cover feedstock materials, finished part properties, system performance and reliability, and qualification principles.

The Additive Manufacturing Standardisation Collaborative (AMSC)

The development of appropriate standards is a key driver for the mainstream adoption of additive manufacturing. However, a consistent approach to this development is needed to facilitate faster industry growth.

In light of this need, America Makes, the US Additive Manufacturing Innovation Institute, and the American National Standards Institute (ANSI) have joined forces to establish the Additive Manufacturing Standardisation Collaborative (AMSC).

Since 2016, AMSC has published two versions of its Standardisation Roadmap for Additive Manufacturing. The roadmap is designed to identify standards (approved and under development), assess gaps and determine priority areas for additional R&D and standardisation. More than 300 individuals from 175 different public and private sector organisations, supported the development of the second version of the Roadmap, published in July 2018.

AMSC’s roadmap provides a snapshot of the current standards landscape for industrial additive manufacturing. Interestingly, it identifies 93 gaps –18 of which are considered a high priority for developing more standards. Gaps include the need to establish a guideline to highlight the trade-offs between additive and subtractive technologies, as well as process-specific design guidelines.

At the end of 2019, America Makes and ANSI also launched an online portal for tracking standardisation activity in AM

Although challenging, tracking and finally bridging standardisation gaps is imperative for AM stakeholders seeking to unlock the potential of additive technologies for production.

The importance of collaboration

Industry collaboration and partnerships have been powerful mechanisms in additive manufacturing, and standards development is no exception. Fostering collaboration provides an excellent opportunity to leverage industrial AM expertise which can help to expand the reach of 3D printing standards for industry.

- For example, SLM Solutions Group has partnered with the German Institute for Standardisation (DIN) to support the latter’s newly-founded Additive Manufacturing Steering Committee. Through its technological expertise, SLM Solutions aims to accelerate the commercial viability of metal 3D printing.

- Collaboration between Oerlikon and Boeing is also set to develop standards for metal 3D printing. Targeting AM use in aerospace and defence, the partnership is focused on standardising materials and processes for powder-based metal 3D printing of structural titanium components.

- Last month, ASTM International invested $300,000 into research projects within Additive Manufacturing Center of Excellence, which target four main areas, including feedstock, process qualification, post-processing, and testing.

- The launch of Additive Manufacturing Center of Excellence this summer is also another milestone for the industry. The new facility, founded by ASTM International in collaboration with Auburn University, NASA, EWI, and the UK-based Manufacturing Technology Centre (MTC), is focused on bridging R&D and standardisation to fill key industry gaps.

While MTC will be developing standards to evaluate quality and recyclability of metal powders, NASA researchers will focus on specifications for laser-based machines and processes. EWI will be studying post-processing to help standardise surface quality and measurement metrics. Finally, Auburn University will be responsible for researching mechanical testing issues in metal AM to help create guidelines on designing specimens to test 3D printed parts.

With a range of key industry stakeholders gathered under one roof, this collaboration could be game-changing for the industry.

Standardisation: shaping the future of 3D printing

‘It would be incredibly beneficial to all stakeholders and constituents if the industry had better standards overall, standards that are universally understood and accepted. With standards, companies can compare apples to apples and make intelligent decisions that can be implemented within a comprehensive ecosystem of suppliers, manufacturers and users.’

Avi Reichental, Founder of XponentialWorks

While 3D printing continues its foray into industrial manufacturing, mainstream adoption of the technology is hampered by challenges concerning part quality, consistency and certification. Standardization can help to address some of the most pressing of these challenges.

To ensure that additive manufacturing continues on the road toward mainstream adoption, standards and guidelines will need to be established. At the same time, however, such developments will take time, potentially even a number of years.

But the benefits are obvious: clear standards will drive the use of 3D printing for production by fostering a common terminology, efficient testing and consistent materials and processes.