| Technique | Mechanical Attribute |

| FDM | anisotropy |

| SLS | isotropic |

| DMLS | isotropic |

| SLA | isotropic |

It’s crucial for industrial and commercial customers to know the physical attributes of different 3D printing techniques, including strength in different axis, which is part of anisotropy and isotropic. We all know the tensile strength varies between types of 3D printing technology and materials, the manufacturing process and structure of the product, etc. And here we want to introduce how strong is a 3D printed object, made from the mainstream of FDM, SLA, SLS, and DMLS, when it’s elongated in X, Y, and Z directions.

A general conclusion for 3D printing

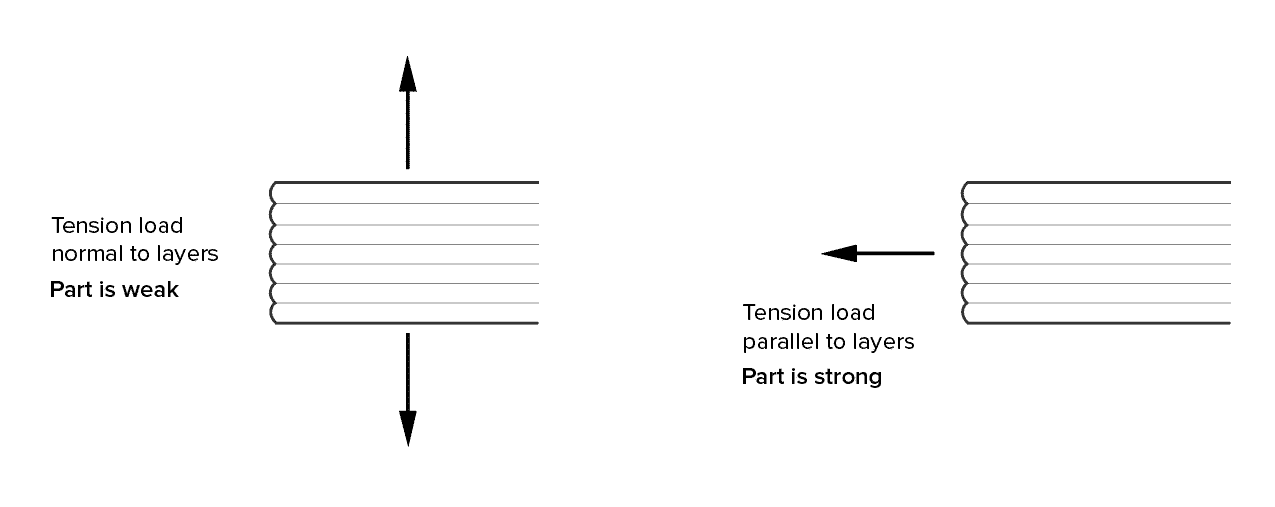

We usually build the object layer by layer, so the strength in the Z-axis is impacted by the internal bonds between the layers. The part made by most 3D printing technologies is strong in X- and Y- axes, and weak in Z-axis, cause the bonds formed between layers are weaker. The general conclusion is: all the internal bonds are referred to as anisotropic, which means their physical properties are different when measured in different directions.

Typically people would rotate the part so that it would be printed with layers matching the required axis of strength, and it often works when part receives mechanical stress from only one direction. Or else you need to choose a compromise axis and it’s restricted by the geometry of the part and the circumstances of its use.

The brief introduction of main 3D printing technology

The difference of strength in various 3D printing technology lies in how the layers are overlaid upon each other. Firstly we need to own the basic knowledge of 3D printing technology.

- FDM, i.e. fused filament fabrication is a method of extruding small beads or streams of material(wax, ABS and nylon) which harden immediately to form layers.

- SLA, known as stereolithography, optical fabrication, photo-solidification or resin printing, produce parts using photochemical processes by which light causes chemical monomers to link together to form polymers.

- SLS: Selective laser sintering, is a technique that uses a laser as the power source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

- DMLS, whose full name is direct metal laser-sintering, can fully melt the alloys and produce products with organic geometries, internal features and challenging passages that could not be cast or otherwise machined.

Z-strength comparison for different techniques

The above-mentioned conclusion is based on generalizations, corresponding with our intuition. It’s more evident for some of the 3D printing techniques when scientists perform experiments on different specimens, but we will briefly sum up the research results and concentrate more on the principle of why the main printing methods behave differently in anisotropy and isotropic attributes.

The principle and experimental results of the difference

The difference can be explained both on mechanical and chemical aspects, the former one focuses on the microscopic bonding effect while the latter one concern about how tightly the polymer chains are entangled.

FDM

When FDM printers melt plastic layers on top of layers, incompact mechanical adhesion (not chemical adhesion) was created. Even when the previous layer is partially melted, the surrounding layers are only partially adhered to their neighboring layers. As a result, FDM-printed objects are pervaded by microscopic voids and holes, thus they are porous. On a molecular level, the highly entangled polymer chains hold each other tightly on the XY plane but behave more individually on the orthogonal Z-axis. Research shows that FDM parts lose approximately more than 55% of their Z-strength.

DMLS & SLS

Out of its production process, the printed object is not likely to delaminate and fracture when placed in tension in the Z direction compared to XY directions. Scientists from Lawrance Technological University conducted research in 2016 with 120 samples built from stainless steel powder using DMLS machines. Those samples revealed the average ultimate tensile strength as well as yield strength in different orientations.Because the principle of DMLS, SLS, and SLM are similar, the corresponding printed objects have good isotropic mechanical properties, making them ideal for functional parts and prototypes.

SLA

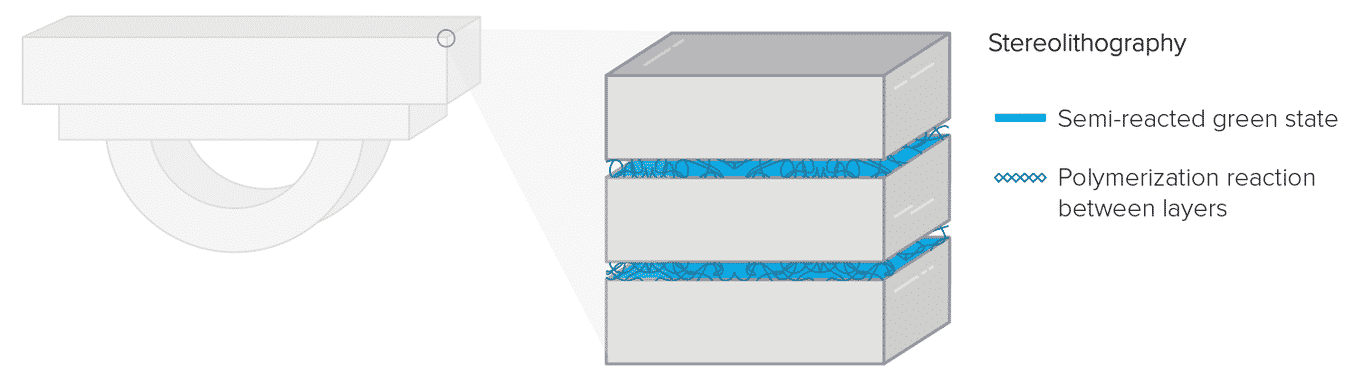

In SLA printing, there is no difference between the Z-axis and XY plane in terms of chemical bonds. There is a polymerization reaction between layers and SLA lines are fully bonded to their neighboring lines. There are no voids or microscopic cracks in SLA prints so that they are watertight and fully dense. The Young’s Modulus data, which is a measure of a solid’s stiffness or resistance to elastic deformation, supports the hypothesis that SLA printed parts are isotropic in fact.

To summarize, FDM < SLS & DMLS & SLA in Z-axis strength tension. FDM parts cannot be equally strong in all directions, which means that orientation should be seriously considered when design and print load-bearing parts. As for DMLS, SLS and SLA, the quality of layer adhesion is excellent, proved to be proper for functional parts.

Some progress for improving the Z-strength

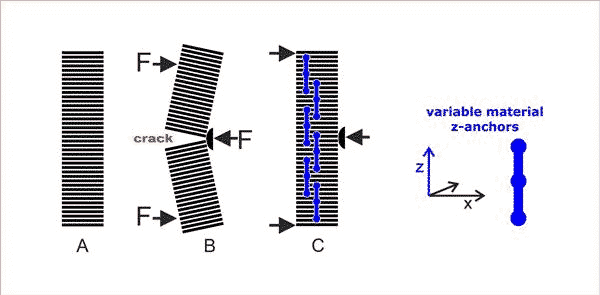

A piece of common knowledge is that you can infuse the vacuum chamber of FDM print with epoxy to help increase tensile strength, which means the higher cost will be generated. In March 2019, Kai Parthy, a specialist who has over 10 years of experimentation about smart filaments, developed a new method that could strengthen FDM 3D printed components locally with little material efforts. His solution is using the Z-anchors as a reinforce to avoid layer cracks, save weight, optimize the local static within the object, and reduce the wall thickness. The principle is shown as below image, Z-anchors can hold the object together and make it more stable in the z-axis. It’s also applicable to SLS and FFF printing techniques. We’d like to share with you the methods of building Z-anchors.