Investment casting can be traced back to ancient Egypt and China 5,500 years ago. It is based on the lost-wax casting method, which is one of the oldest known metal-forming techniques, and developed to be a widespread modern casting process. In recent years, 3D printing becomes increasingly popular in producing the pattern for the expendable investment casting. It delivers changes in the manufacturing industry by reducing lead time, eliminating high tooling costs, producing parts with flexible and complex geometry structure, etc.

The Traditional Investment Casting Process

Investment casting is also called precision casting and lost-foam casting. Its name derives from the process that wax pattern is firstly invested (surrounded) with a refractory material like ceramic, and then the pattern will be melt or vaporized in the furnace. The value of investment casting embodies in its ability to produce parts with accuracy, repeatability, versatility in abundant choices of high-performance metals and alloys.

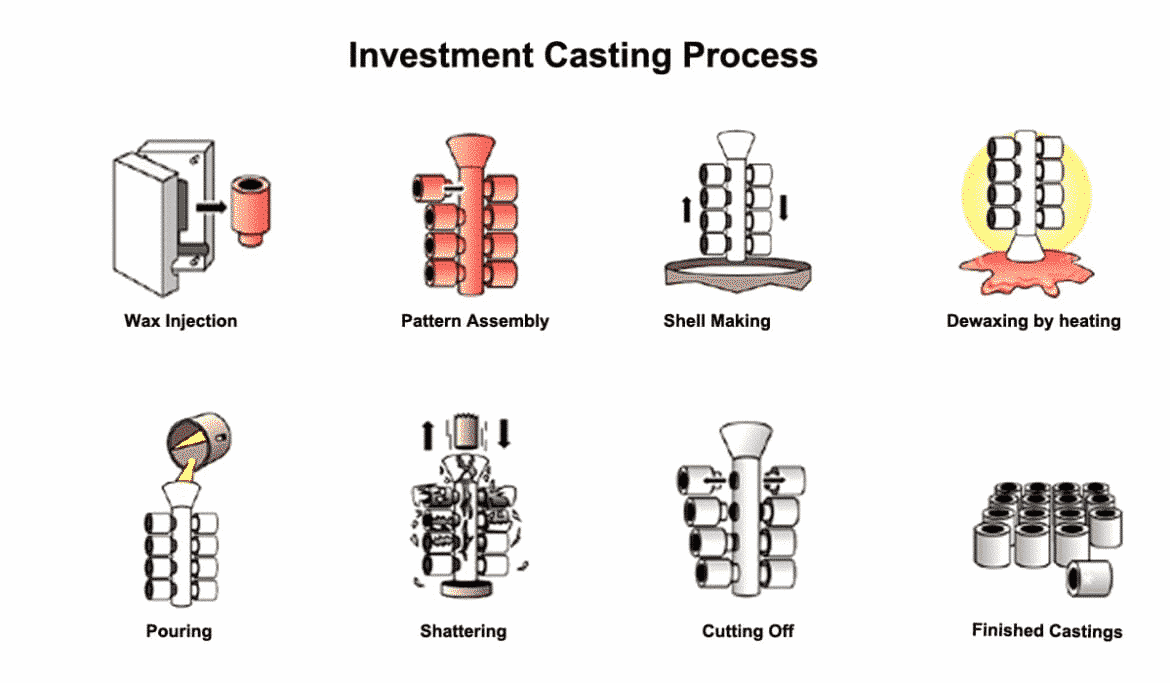

The process of investment casting has been standardized and can be summarized in the below steps:

- Inject the molten wax into the pattern mold and wait for its cooling and hardening into a wax pattern.

- Assemble the wax pattern onto a “wax pattern tree” with a wax sprue (a gate to pour the liquid metal material in).

- Repeatedly submerge the tree into a ceramic slurry and sand alternately to form a rigid and thick outer shell. When the ceramic shell drys out, the whole part becomes an investment mold.

- Heat the investment mold rapidly so that the wax can melt and drain quickly to minimize the inner stress and make space for the wax expansion.

- Heat the investment mold to remove moisture and residual wax, then pour the material into the mold by gravity or air pressure.

- Remove the investment shell from the casting part by hammering, basting or other methods.

- Saw off the casting part from the tree and conduct the finish process.

There are some key points among those steps:

- The pattern mold requires special tools and the building process of which may take 8-20 weeks and cost $50,000 – $100,000, depending on the complexity of the parts.

- The pattern mold must be subtly made and it’s not convenient to modify and verify design plans.

- During dewaxing, the heated wax expands and increases the inner pressure, which is possible to lead the explosion of the investment mold.

What is the SLA 3D printing?

SLA is also known as stereolithography apparatus, optical fabrication, photo-solidification or resin printing. It is a type of 3D printing technology and targets at creating models, prototypes, patterns, and production types. The principle is focusing a UV laser on photopolymer resin and the resin, which is sensitive to ultraviolet light, will be solidified and form a single layer and ultimately make up the body of a three-dimensional solid object.

SLA printing technique is extensively used in plenty of fields as it’s distinctive in:

- Shortening the lead time to a large extent;

- Applying on a wide range of materials;

- Producing high-accuracy, isotropic and watertight objects with excellent qualities and smooth surface finish.

SLA Quick Precise Casting Method

The advent of SLA has triggered a revolution in the casting industry and people name it SLA Quick Precise Casting Method. Below we listed the main difference in the steps of casting:

- Designing There is no need to create a tool to build the pattern mold anymore. Instead, the pattern is designed in CAD and printed directly by the SLA printer. It can fully realize the exact specifications of customers. The gate and runner structure can also be built in advance, no need to be injected in the shelling process. When using stereolithography patterns, it’s easy to modify the original design of the pattern mold and examine the results in just a few days.

- Pattern creation

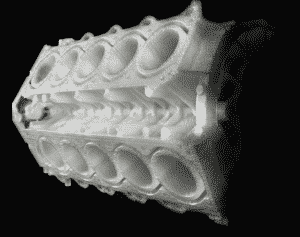

The material of the pattern mold should meet several requirements: leave little or no ash residue after burnout; can form a smooth surface; the structural integrity can be maintained over a period; do not swell due to water absorption. We recommend Somos, one of the best resins which can perfectly meet the requires, to substitute wax in making the pattern. It also allows customers to cast a complicated object while wax can’t make it in some condition. - Shelling process Little difference compared with traditional investment casting process existed in this step.

- Burnout

As for the dewaxing, there is a less thermal expansion of the resin due to its internal structure. With the help of the software QuickCast, we can print the pattern mold with both a cellular internal structure and a smooth and compact surface. When it’s heated, the resin will collapse inward and avoid the failure of shell cracking.

- Casting

Little difference compared with the traditional investment casting process existed in this step.

The Advantages of SLA Technique in the Casting Industry

- The SLA printed patterns can be 25% lighter than conventional patterns.

- Eradicate the process of tooling and molding so the total around time can be reduced to 1-3 weeks, and the entire production cost is cut down sharply.

- Offer relatively greater flexibility for designers while the quality and precision are also ensured.

- Convenient for trial and error in optimizing the design plans – modify the parameters in CAD and the printing machine will automatically yield samples.

- The great potential of expanding its boundries and serving more markets.

Which Circumstances are Suitable for SLA Quick Precise Casting Method?

- There is no final design plan, and you want to optimize the plan by modifying and pre-producing the wax pattern.

- You are in a rush and the parts must be delivered in the lead time.

- The required volume is low (less than 50) thus molding and tooling are too demanding and costing for you.

- The designed special structure is not possible to be molding, and

- Some trial samples are needed to prove your assumption of supposes.