Strassacker is one of the oldest and largest art foundries in Europe, producing well-known artworks such as the bronze trophy of the Bambi Award of German media. Strassacker has become an art manufacturing partner for many of the world’s leading contemporary artists.

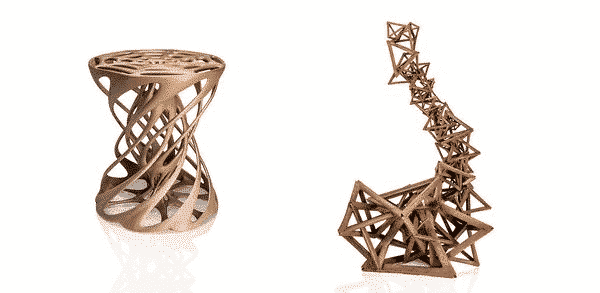

In addition to the traditional casting process, Strassacker gradually introduced the Binder Jetting 3D printing technology to the casting process of bronze artwork. In this issue, Facfox will share examples of artworks produced by Strassacker in collaboration with Voxeljet AG, in order to show the possibilities of spray adhesive in 3D printing technology for sculpture art.

Here are two examples in hundreds of successful artwork Strassascker accomplished.

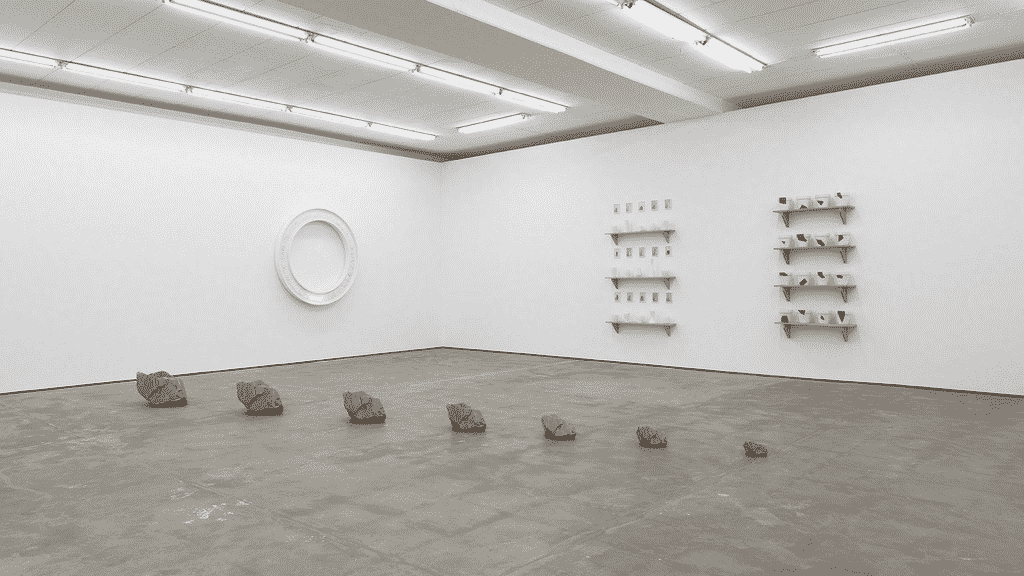

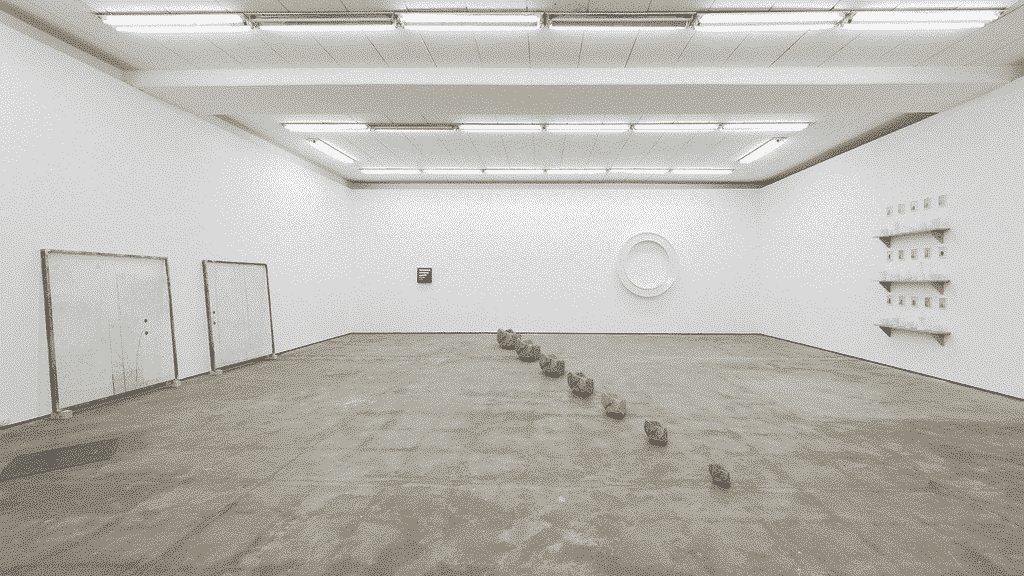

Wachsende Steine by Timm Ulrichs

The work “Wachsende Steine” (“Growing Stone”), which consists of one quartz stone and six uniform but different sized bronze castings, is located centrally on the gallery floor and presents the visitor with the riddle of ancient rock and replicas.

The 74-year-old artist likes to ennoble the copy and leave the original in the shade. Those copy stones are made through the below procedure:

- 3D scan the real stone and digitize it

- Scale the 3D model to the desired size

- 3D print with PMMA in several parts by Voxeljet

- Assemble the parts into a large “stone” and prepare for casting

- Cast the PMMA stone in bronze-like casting the conventional wax model

- Patinate the bronze models by hand

- Airbrush to make it more like the natural stone

Bronze reconstructions of the “Boxer at Rest” and the “Hellenistic Prince” sculptures by Prof. Dr. Vinzenz Brinkmann

The sculptures “Boxer at Rest” and the “Hellenistic Prince” seems to be originally handmade between the 4th and 1st centuries BC and rediscovered on the Quirinal in Rome in 1885.

Liebieghaus Sculpture Museum has led in the area of unraveling the mystery of the original polychromy of ancient sculptures. The archaeologists Vinzenz Brinkmann and Ulrike Koch-Brinkmann think of using 3D printing to build bronze reconstructions of those sculptures, which used to be richly clothed in vivid colors but have their color deceiving during centuries.

- 3D scan the original sculptures and digitize it

- 3D print with PMMA by Voxeljet in Strassacker’s service center in Friedberg, Bavaria

- Cast the pattern with bronze and chisel by hand

- Partially restore and patinate the model

- Post-process is done by archaeologists in Liebieghaus Sculpture Museum

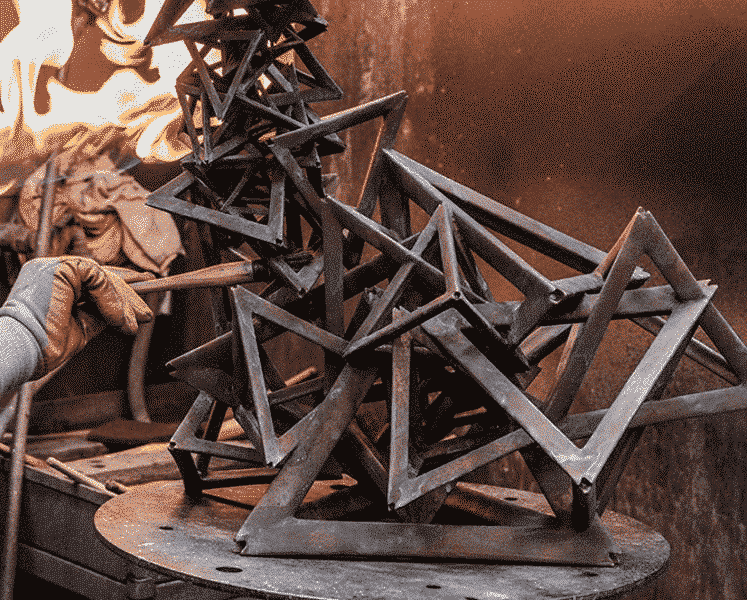

In these cases, Strassacker uses Voxeljet’s 3D printing service to cast bronze models. After the printing of the casting molds, Voxeljet penetrates the models with wax to make the surfaces smoother, and then delivers them to Strassacker, usually within 3-5 days.

The characteristic of this process is that there is no need to create a silicone negative mold. The 3D printed PMMA model is directly immersed in ceramic to create a shell. The model is burned in a 700 ° C furnace, leaving a ceramic mold for casting.

Strassacker has long realized the potential of 3D printing. For more than 15 years, Strassacker has been using 3D printed models in the casting process. Voxeljet industrial 3D printing system can 3D print or cast models with PMMA or silica sand.

Strassacker’s manufacturing process includes traditional manual methods as well as digital methods, also a combination of those two. The art designer can send the completed CAD file to Strassacker, and they discuss the design schemes to determine whether it’s meaningful to apply 3D printing in this work.

Peter Mühlhäußer, product line manager at Strassacker, said that “There are hardly any limits to the ideas, but you still need to develop them yourself. The same way you have to know where the application of technology makes sense and where it doesn’t. Our technicians, designers, and 3D modeling experts are the right people to talk to, in order to define the right technological execution.”