The carbon fiber composite material processing technology is constantly evolving based on the characteristics of a class of products. It varies on the characteristics of the material and the application field. Carbon fiber composite materials, which are light-weighted and have high-strength.

Those materials can adopt different molding manufacturing processes according to different application objects, so as to maximize the special properties of carbon fiber materials.

Maybe you already know that urethane casting is a common-used process to produce a glass fiber or carbon fiber surface. This article will give a brief summary of the carbon fiber composite material forming process and application.

Hand Lay-Up Process

Hand lay-up technique is to apply the release agent and gel coat on the surface of the mold, lay the pre-cut carbon fiber prepreg on the working surface of the mold, brush or spray the resin glue on the working surface to reach the required thickness, and then solidify, demoulding and post-treatment.

Today, the molding technology is highly developed, and the hand lay-up technique is still irreplaceable due to the advantages like the simple process, low investment, and wide application. It is widely used in many fields such as the petrochemical industry, storage containers, and automobile shells.

Its disadvantages are bad densification, low precision, rough surface, low strength, unstable quality, low production efficiency, heavy reliance on human sources, and difficulty in batching and standardization.

Injection Molding Process

It belongs to the category of low-pressure molding process which subordinates to the hand lay-up molding technique. Generally, chopped fibers and resin are mixed, and sprayed on the mold surface evenly from a spray gun with the help of compression air. When the thickness of the mixed materials is ideal, we brush them back and forth with a hand-made rubber trowel, and they finally solidify.

It’s a semi-mechanized molding process created to improve the hand lay-up molding process in production efficiency. It is mostly used to manufacture the transition layers for automobile bodies, hulls, bathtubs, and storage tanks.

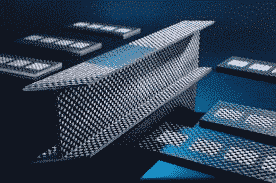

Lamination Process

Placing the prepreg layer-by-layer between the upper and lower flat molds and curing by pressure and high temperature, this process can directly use the production method and equipment of wooden plywood, and further improve it according to the flow properties of the resin.

This molding process is mainly used to produce composite material plates with different specifications and uses. It has the characteristics of high degree of mechanization and automation, stable product quality, and batch utilization, but the equipment investment is large and the cost is high.

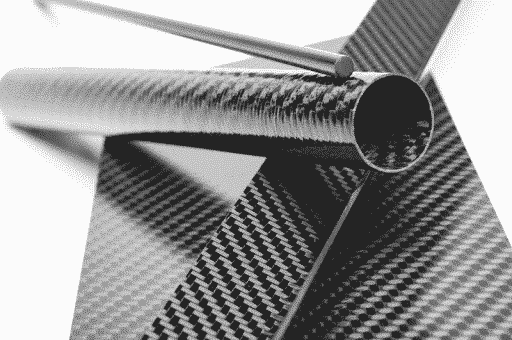

Pultrusion Process

During this process, the fiber or carbon cloth which has been impregnated with resin liquid is put into the extrusion die, and then cured, demoulded, and post-processed into a composite product continuously under the pulling force.

The pultrusion process of composite material is a special one in the forming process. Its remarkable feature is that it can fully realize the automation of the production process, high production efficiency, and has the capacity of mass production.

The fiber mass fraction of extruded products can reach 75%. The resin-impregnated liquid can be carried out under tension, gives full play to the role of reinforcement, thus the product has high strength. Also, the horizontal and vertical strength of the finished products can be adjusted arbitrarily, which can meet different mechanical requirements of carbon fiber composite products.

The forming process is suitable for the production of various cross-section shapes, such as I-shaped, angle shaped, groove-shaped, special-shaped and other kinds of pipes.

Liquid forming Process

The liquid forming process is a kind of product forming process which can synthesize liquid monomers into a polymer, and then change polymer curing reaction into a one-step process in the mold.

This process not only reduces the energy loss but also shortens the production cycle and reduces the production cost (it takes about 2 minutes to complete a product).

However, the popularization of this process must be based on accurate pipeline transportation and material measurement as well as automatic control of temperature and pressure.

This process belongs to the interdisciplinary category of polymer materials and modern high-tech science and technology, and is subject to the development of science and technology. At present, it is not widely used.

Vacuum Autoclave Process

This process is to lay the composite blank which consists of single-layer prepreg in the preset direction into the autoclave, and complete the curing process under a certain preset temperature and pressure.

The autoclave is a kind of special pressure vessel that can bear and adjust the range of temperature and pressure. The blank is laid on the mold surface coated with a release agent, and then completely covered with release cloth, adhesive absorbent felt and air-permeable felt in turn, sealed in a vacuum bag, and then put into a hot pressing tank.

The key to ensuring the quality of composite products is to vacuum before putting it into the autoclave for heating and curing, and then to formulate and implement under high temperature, pressure, and curing.

This forming process is suitable for manufacturing fairings, aircraft doors, airborne radomes, brackets, wings, tails, and other products.

Vacuum Induction Process

The vacuum introduction process is also called VIP. The carbon fiber composite cloth is laid on the surface of the mold, then the vacuum bag is wrapped around it, and the air is drawn out to form a negative pressure inside the vacuum bag and the mold.

The unsaturated resin is pressed into the carbon fiber layer by the pressure generated during the vacuum extraction process through the pre-laid pipeline. So that the resin flows evenly between the carbon fiber cloth.

Finally, the whole product layer is filled evenly. After the high-temperature product solidifies, the vacuum bag is removed and the required product is obtained after the mold is separated.

The process has a patent record since its appearance, but its real popularity occurs in recent years. In the vacuum environment, the resin soaks the carbon fiber cloth, produces fewer bubbles in the vacuum bag. The strength of the product is higher, the quality is lighter, the quality stability is better, and the use of the resin is reduced.

So long as one side of the mold is smooth, the two sides of the product can also be smooth, and the thickness of the product is better controlled. It is generally used to produce rudder, radar shield, wind turbine blade, engine room cover, lightweight refit parts, windshield, car, engine cover, etc.

High-Temperature Molding process

Lay the carbon fiber prepreg flat between the upper and lower molds, seal the molds tightly, place the molds on the hydraulic molding platform, cure the resin and prepreg on the hot press after a certain period of high temperature and pressure, and remove the carbon fiber products from the hot press.

This forming process has the advantages of high strength, high precision, lightweight, little environmental impact, and is suitable for mass production and standardization.

Molding technology has been used for many years in foreign countries, but it’s applied in China recently. It is convenient to form components in the industry. In the production process, the filling amount of resin can be effectively controlled, and the fiber has good wettability, high carbon fiber content, so it has the characteristics of high strength, high precision, short molding cycle, etc.

If the environment is good, it can reach the scale production of 50,000-80,000 pieces per year. China’s high-speed railway uses this molding process to produce some structural parts, which effectively solves the problem of difficult connection between carbon fiber and metal after the product is formed, and effectively ensures the mechanical strength and mechanical requirements of the parts.

According to the feedback from the high-speed railway manufacturers, the light, high-strength, aging resistant and long-life carbon fiber structural parts have achieved their expectations. From the application results, it can be concluded that the carbon fiber products using this molding process can also be applied to more products, such as the interior decorative parts, handrails, body accessories, spare parts and so on.

3iTech induction heating process

This is a new induction heating process that integrates sensors into the mold. It can process carbon fiber materials at a temperature of 20 ℃ – 400 ℃, and heat the mold surface with temperature sensors.

This is a supplementary technology introduced by RocTool on the Cage system. The mold can be heated quickly and the local temperature can be well controlled by using electromagnetic induction. Its advantage is to reduce the production cycle and production costs. However, at present, this technology is not suitable for the production of large-scale parts. It’s mostly used for the production of mass products.

With the development of science and technology and the in-depth application of carbon fiber composite materials, the forming process of carbon fiber composite materials will continue to improve and innovate. However, in the reproduction process of carbon fiber composite materials, not only one process is used, but a variety of processes are used together to achieve the maximum optimal allocation of resources.